Feeding device for C-shaped annular thin sheet

A technology of feeding device and sheet, which is applied in thin material handling, transportation and packaging, and separation of objects, etc., can solve the problems of producing substandard products, easy deformation, restricting automatic production, etc., and achieves convenient processing and manufacturing, simple device structure, and high reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

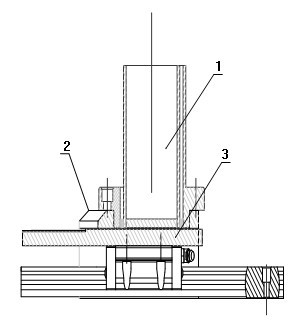

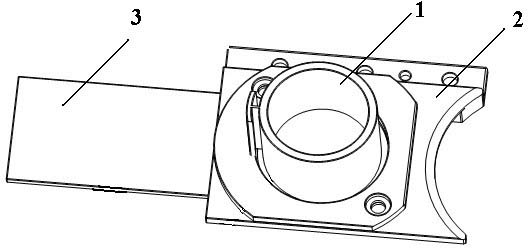

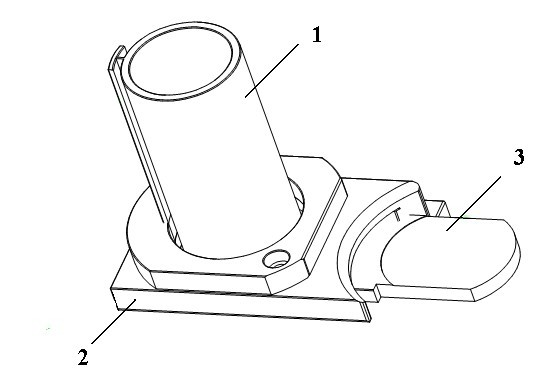

[0014] Example: The feeding device for C-shaped annular sheets of the present invention includes a barrel 1, a fixed bracket 2, a push plate 3, a slide rail 5 and a driving device 6; the slide rail 5 is fixed on a workbench; The plate 3 is connected with the driving device 6 and slides back and forth along the slide rail 5. The upper surface of the push plate 3 is a stepped surface with a low front and a high rear, and the height of the steps is equal to the thickness of the C-shaped annular sheet; The barrel 1 is fixed directly above the push plate 3 through the fixing bracket 2 , and the lower bottom surface of the barrel 1 is level with the upper stepped surface of the push plate 3 . The material cylinder 1 is a double cylinder structure composed of an inner cylinder and an outer cylinder, a longitudinal partition is arranged between the outer wall of the inner cylinder and the inner wall of the outer cylinder, and a C-shaped annular sheet is arranged in the gap between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com