Dielectric-adjustable low-temperature co-firing ceramic material and preparation method thereof

A ceramic powder and dielectric technology, which is applied in the field of preparation of composite microwave ceramic materials and low-temperature co-fired ceramic devices, can solve the problem of low dielectric constant and achieve low cost, environmental protection, non-toxic side effects, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

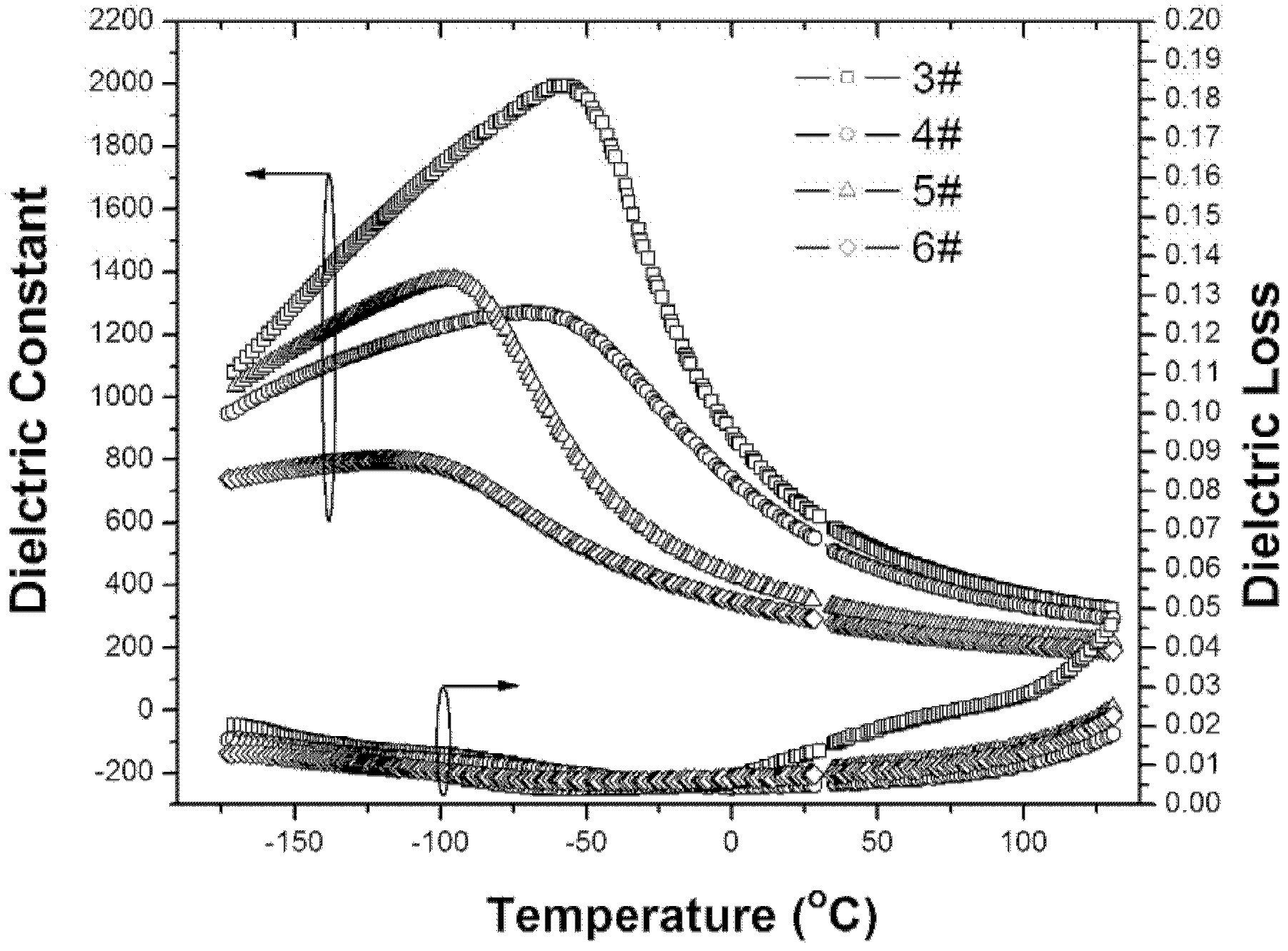

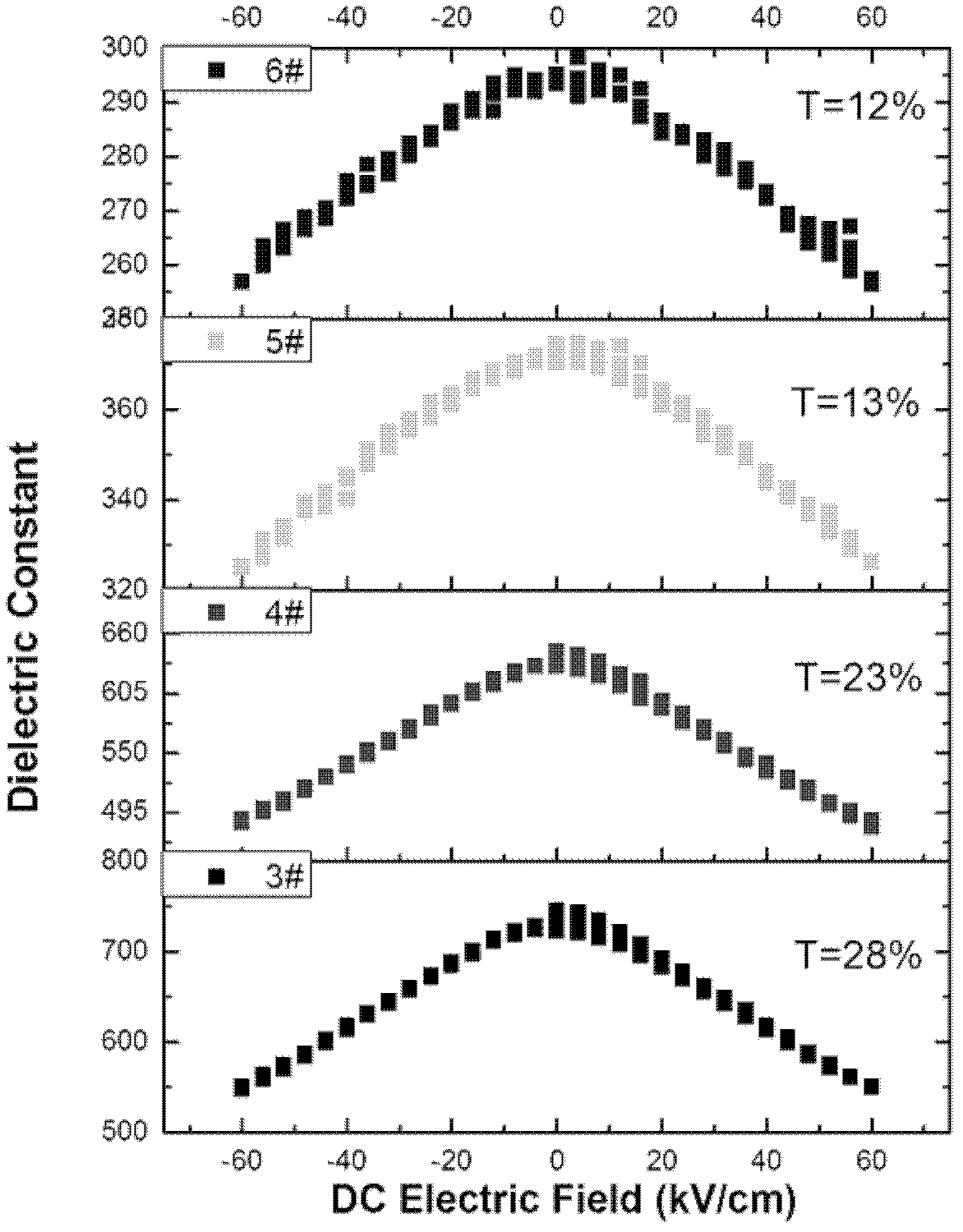

[0033] Ba 1-x Sr x TiO 3 -AMoO 4 Preparation of (A=Ba, Sr or Ca) Low Temperature Co-fired Ceramics

[0034] Table 1

[0035]

[0036]

[0037] Take by weighing Ba respectively according to the component distribution ratio in each embodiment in table 1 1-x Sr x TiO 3 (x=0.4~0.6) Powder, AMoO 4 (A=Ba, Sr, Ca) powder and yB 2 o 3 ·zLi 2 O powder, add zirconia balls and absolute ethanol or water, ball mill for 20 to 24 hours, discharge, dry and grind into powder, pass through a 200-mesh sieve to obtain the required low-temperature co-fired ceramic material.

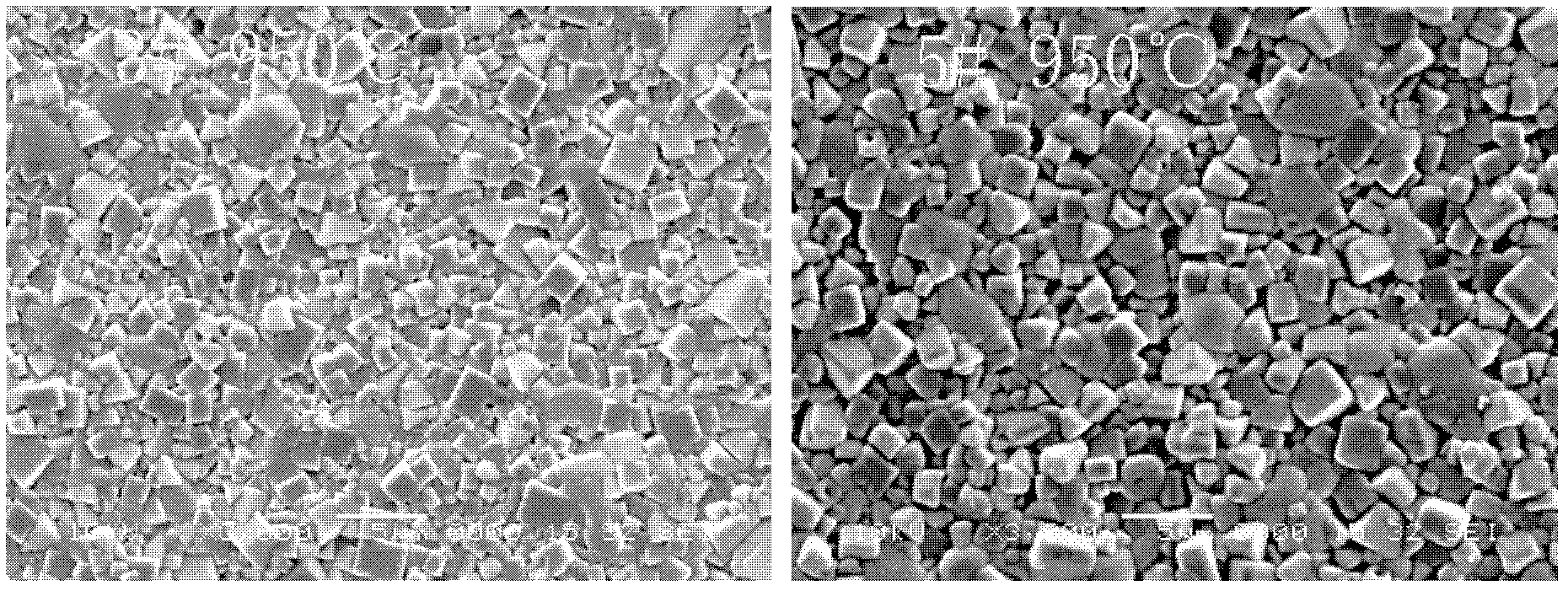

[0038] According to the traditional electronic ceramics preparation process, 8% polyvinyl alcohol (PVA) is used as a binder for granulation, and the granulated low-temperature co-fired ceramic material is dry-pressed into diameters under a pressure of 10 MPa. Green sheet, after debonding treatment at 550°C, the sample is sintered in the air atmosphere, the sintering temperature is in the range of 900-950°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com