Blast furnace top flange jackscrew aligning method

A technology of blast furnace and top wire, which is applied in the direction of blast furnace, blast furnace details, blast furnace parts, etc., can solve the problems that affect the installation period of furnace top equipment, labor and time, and inconvenient operation, so as to shorten the alignment time, reduce costs, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

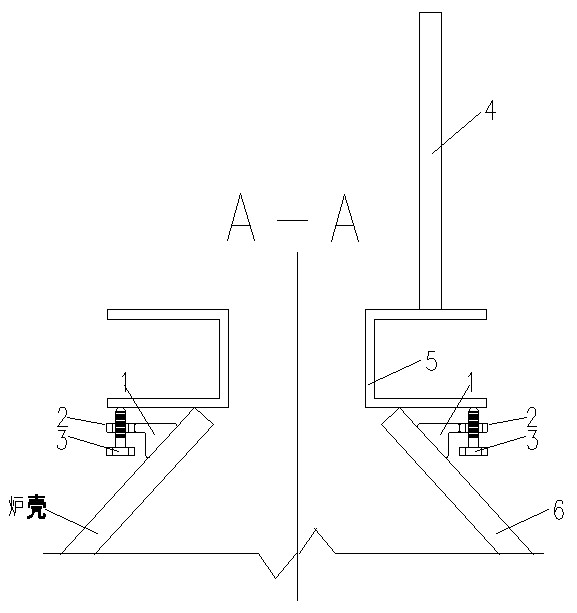

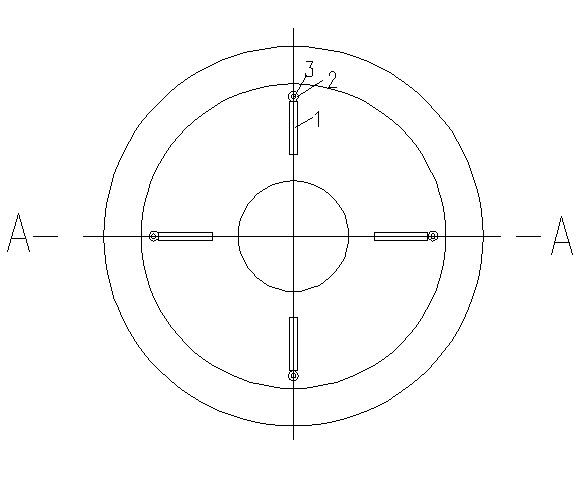

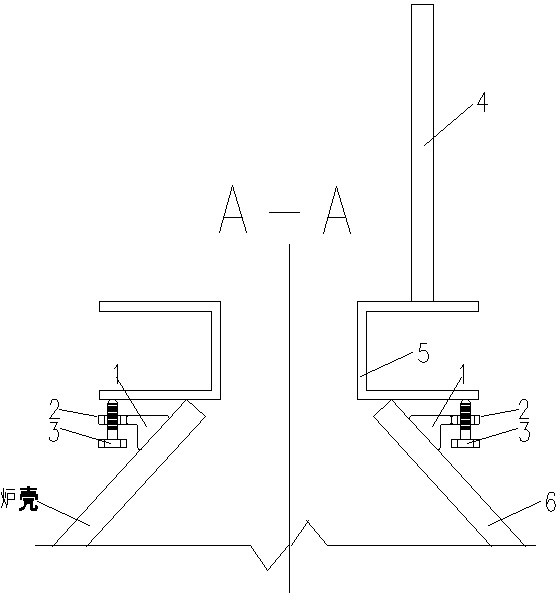

[0018] In order to further describe the present invention, the method for aligning the top wire of the blast furnace roof flange of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0019] As shown in the figure, the method for aligning the top wire of the blast furnace roof flange is characterized in that the adjusting nut (3) of the top wire (2) is first welded to the end of the 20mm thick steel plate (1), and then the four A steel plate (1) welded with an adjusting nut (3) is welded to the furnace shell (6) directly below the cross center of the furnace top flange (5), and the adjusting nut (3) is internally screwed onto a semicircular top wire (2), according to the actual height difference measured by the measuring tower ruler (4) level, adjust the levelness of the flange by adjusting the jacking screw (2).

[0020] The method of aligning the top flange top wire of the blast furnace roof is carried out ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com