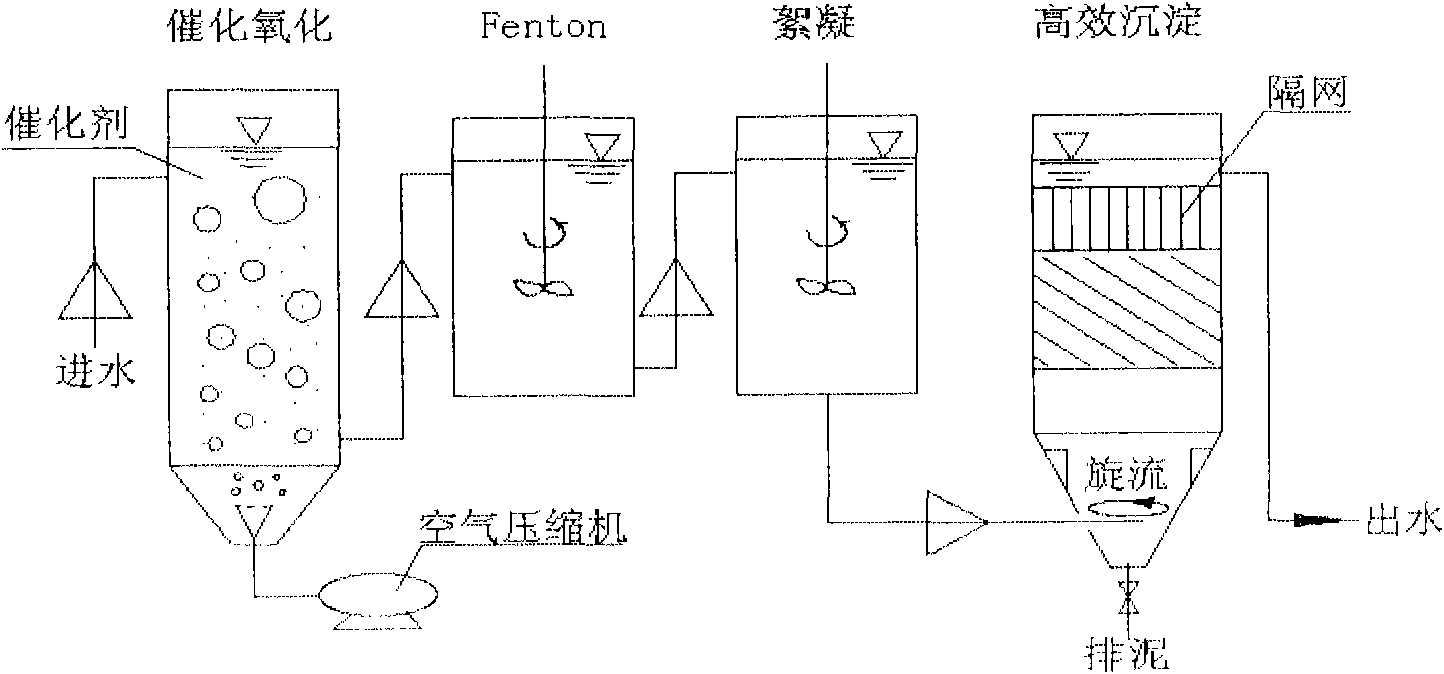

Process for catalytic oxidation-compound flocculation integrated treatment of comprehensive waste water

A catalytic oxidation and comprehensive wastewater technology, which is applied in the direction of oxidized water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of low process integration, cumbersome operation, and complicated process , to achieve the effect of shortening the flocculation time, reducing the dosage and improving the flocculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] ① Put the comprehensive chemical wastewater with a pH value of 6.8, a turbidity of 95 NTU, a chromaticity of 1700, and a COD of 836 mg / L into the catalytic oxidation reactor, and add nano-iron oxide catalyst at a rate of 100 mg / L, and add 1.2 L / L s m 2 The aeration intensity is aerated with air, and the reaction is 20 minutes;

[0030] ② Add FeSO to the wastewater at concentrations of 360mg / L and 4.0mmol / L respectively 4 ·7H 2 O and H 2 o 2 , and reacted for 30min at a stirring speed of 200r / min;

[0031] ③Add cationic PAM at a concentration of 0.5mg / L, stir rapidly at a speed of 300r / min for 3min, and then stir slowly at a speed of 40r / min for 10min;

[0032] ④Wastewater enters the high-efficiency slanted plate sedimentation tank, settles for 15 minutes, and exits.

[0033] After being treated by this process, the turbidity of the effluent is less than 5NTU, the chroma is less than 25, the COD is less than 120mg / L, and the removal rates are over 95%, 98% and 85% ...

Embodiment 2

[0035] ①Put the comprehensive chemical wastewater with a pH value of 6.98, a turbidity of 148.9NTU, a chromaticity of 1763, and a COD of 2320mg / L into the catalytic oxidation reactor. / s·m 2 The aeration intensity is aerated with air, and the reaction is 35 minutes;

[0036] ② Add FeSO to wastewater at concentrations of 600mg / L and 6.5mmol / L respectively 4 ·7H 2 O and H 2 o 2 , and reacted for 60min at a stirring speed of 200r / min;

[0037] ③ Add cationic PAM at a concentration of 0.9mg / L, stir rapidly at a speed of 300r / min for 5min, and then stir slowly at a speed of 40r / min for 15min;

[0038] ④Wastewater enters the high-efficiency slanted plate sedimentation tank, settles for 30 minutes, and exits.

[0039] After being treated by this process, the turbidity of the effluent is less than 8NTU, the chroma is less than 27, the COD is less than 280mg / L, and the removal rates are over 94%, 98% and 87% respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cod | aaaaa | aaaaa |

| Cod | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com