Method for obtaining keratin from feather

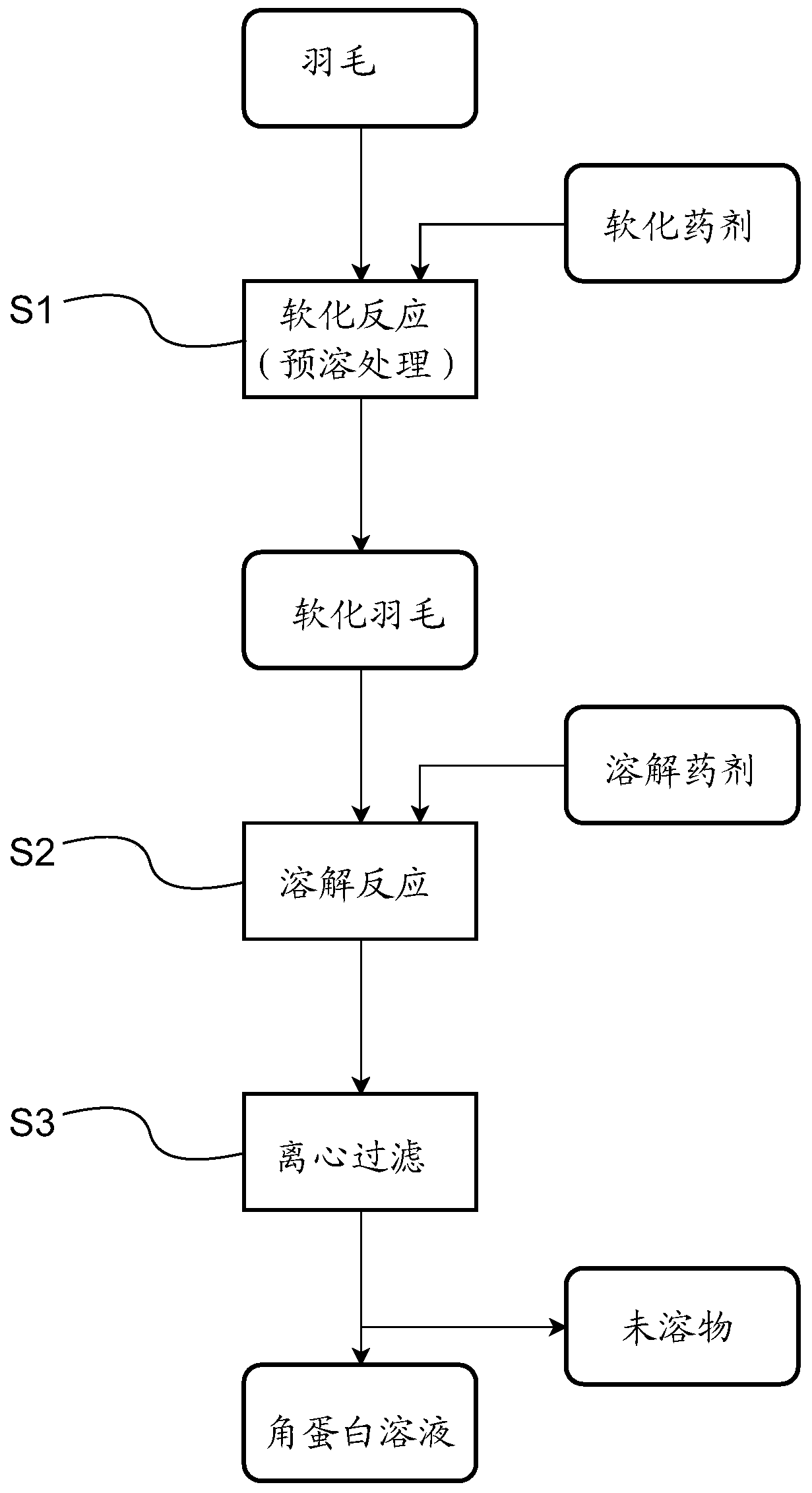

A keratin and feather technology, applied in the field of keratin extraction, can solve the problems of high proportion of water bath, cleaning machine, difficult maintenance, high equipment cost, etc., and achieve the effect of reducing reaction time, increasing added value, and short operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

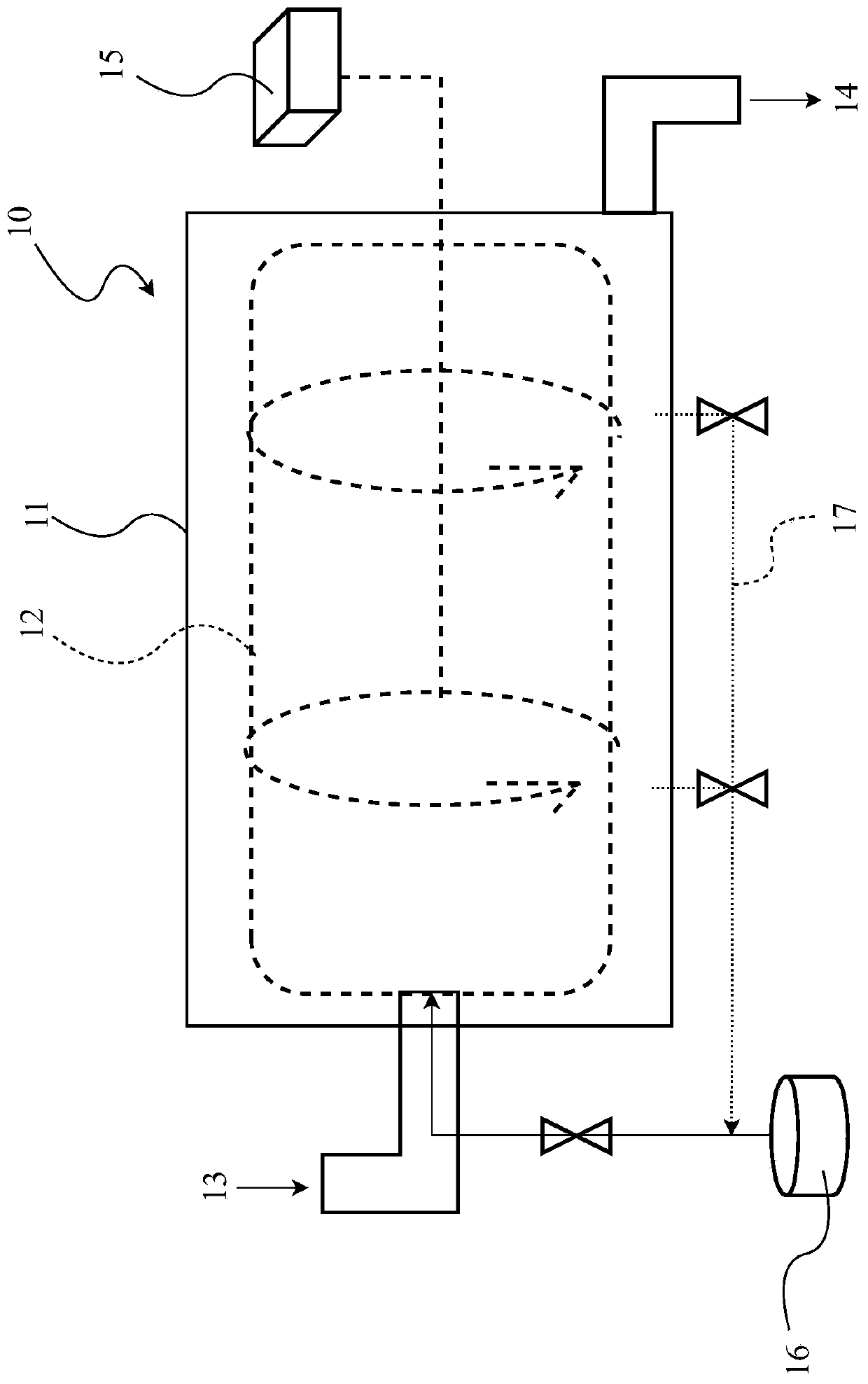

Embodiment 1

[0054] 1. Fill 1 kg of feather material (with feather stalk / rachis, washed and crushed) into the inner tank;

[0055] 2. Inject clean water and hydrogen peroxide (softening agent), and mix to form an aqueous solution with a hydrogen peroxide concentration of about 15-20%. °C to 60 °C;

[0056] 3. Drive the inner tank to stir continuously in a circle of two seconds, and keep it for 30 minutes for softening reaction;

[0057] 4. Add the prepared dissolving agent (which contains SDS, Urea, βME), mix into the aqueous solution to form an aqueous solution containing 0.02MSDS, 0.6M Urea and 0.1M βME (such as about 150g of SDS, 1kg of Urea and 150g of βME), and raise the temperature to 85°C;

[0058] 5. Drive the inner tank to stir continuously in a circle of two seconds, and maintain the dissolution reaction for 30-60 minutes;

[0059] 6. Drive the inner tank at a speed of about 800rpm, run for about five minutes to discharge, separate the undissolved matter and the aqueous soluti...

Embodiment 2

[0062] 1. Fill 1 kg of feather material (with feather stalk / rachis, washed and crushed) into the inner tank;

[0063] 2. Inject clean water and hydrogen peroxide (softening agent), and mix to form an aqueous solution with a hydrogen peroxide concentration of about 35-50%. The aqueous solution is about 10 times the weight of a feather, and the temperature reaches 60°C;

[0064] 3. Drive the inner tank to stir continuously in a circle of two seconds, and keep it for 30 minutes for softening reaction;

[0065] 4. Add the prepared dissolving agent (including SDS, Urea, βME), mix it into the aqueous solution to form an aqueous solution containing 0.02MSDS, 0.6M Urea and 0.08M βME, and raise the temperature to 85°C;

[0066] 5. Drive the inner tank to stir continuously in a circle of two seconds, and maintain the dissolution reaction for 30 minutes;

[0067] 6. Drive the inner tank at a speed of about 800rpm, run for about five minutes to discharge, separate the undissolved matter ...

Embodiment 3

[0070] 1. Fill 1 kg of feather material (with feather stalk / rachis, washed and crushed) into the inner tank;

[0071] 2. Inject clean water and NaOH (softening agent), mix to form an aqueous solution with a NaOH concentration of about 0.5N, the aqueous solution is about 10 times the weight of the feather, and the temperature reaches 60°C;

[0072] 3. Drive the inner tank to stir continuously in a circle of two seconds, and keep it for 30 minutes for softening reaction;

[0073] 4. Add the prepared dissolving agent (including SDS, Urea, βME), mix it into the aqueous solution to form an aqueous solution containing 0.005MSDS, 0.25M Urea and 0.08M βME, and raise the temperature to 85°C;

[0074] 5. Drive the inner tank to stir continuously in a circle of two seconds, and maintain the dissolution reaction for 60 minutes;

[0075] 6. Drive the inner tank at a speed of about 800rpm, run for about five minutes to discharge, separate the undissolved matter and the aqueous solution con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com