Vacuum sputtering device and use method thereof

A technology of vacuum sputtering and sputtering, which is used in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions, and can solve the problems of poor sputtering effect, air leakage, and poor sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

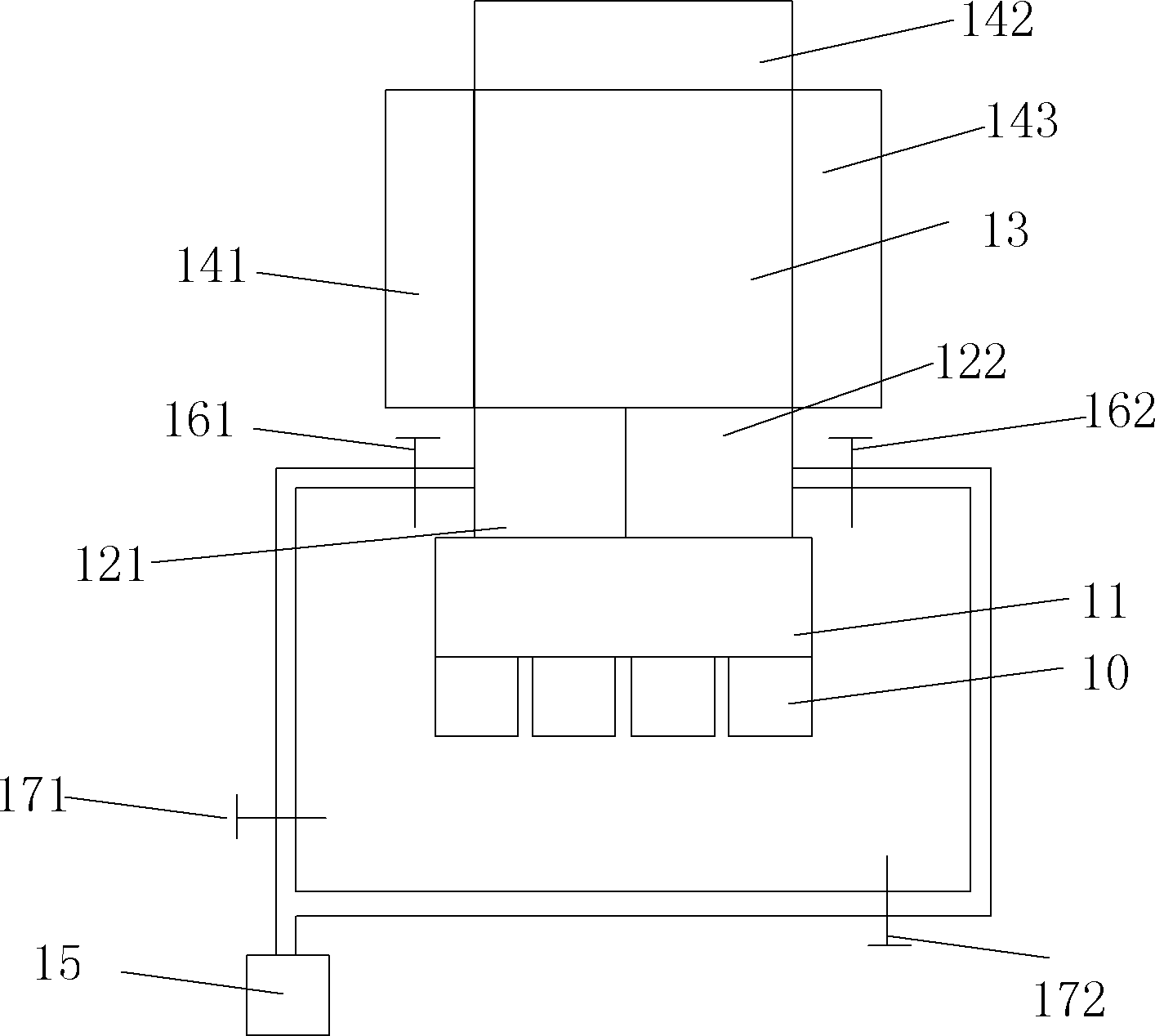

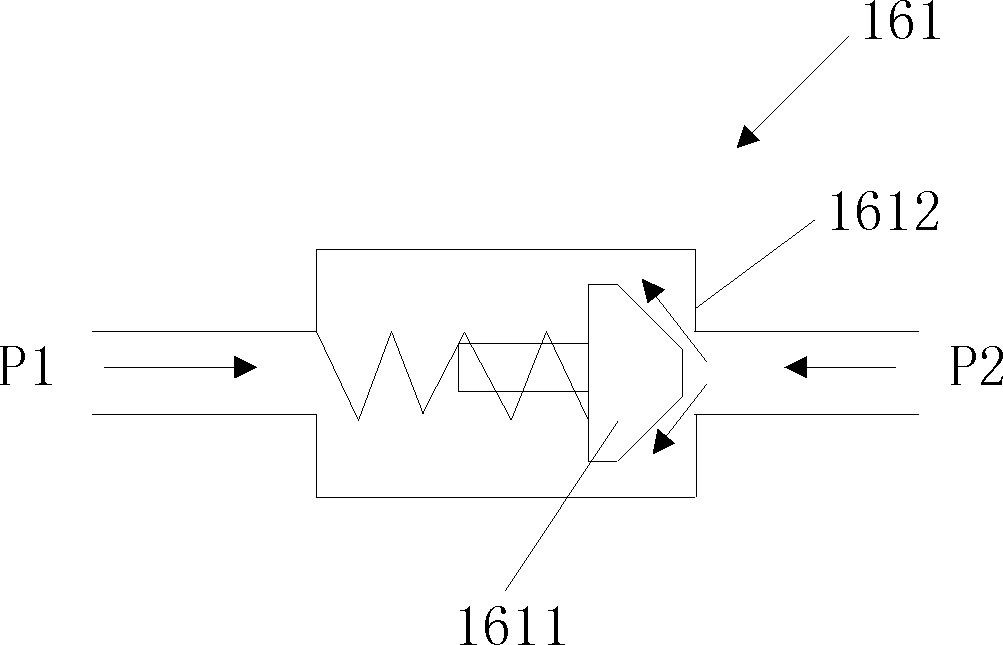

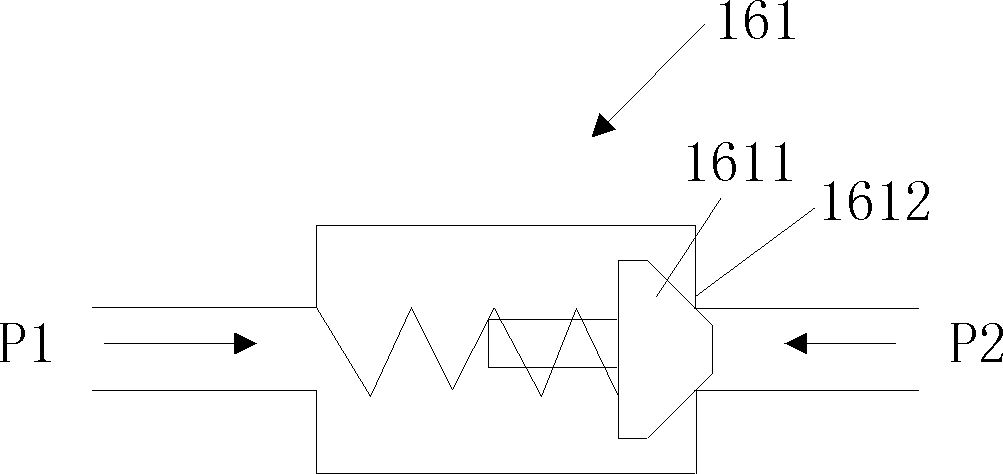

[0034] As mentioned in the background technology, the vacuuming process of multiple exit / entry chambers is realized by one vacuum pump. Therefore, when the vacuum degree of a certain cavity reaches a certain requirement, the valve arranged between the vacuum pump and the exit / entry chamber is closed, and the other chambers are closed. The chamber is still being evacuated or undergoing a transfer process. However, due to the long-term use of the valve or the corrosion of the inert plasma gas in the sputtering environment, the gasket of the chamber whose vacuum degree reaches a certain level may be worn out, and the seal may not be good, resulting in the entry of external gas and gas backflow. To solve this problem, the present invention proposes that at least two airflow isolation devices are arranged between each of the outlet / inlet chambers and the vacuum pump, at least one of which can automatically prevent gas from flowing into the outlet / inlet chambers. In this way, the qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com