A kind of preparation method of polyimide modified nylon resin

A polyimide and modified nylon technology, which is applied in the field of thermoplastic polyimide modified nylon resin, can solve the problems of limiting the research scope of modification and narrow selection of substrates, so as to improve water absorption and toughness, The effect of high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

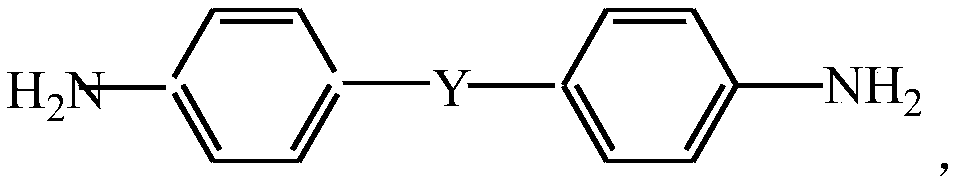

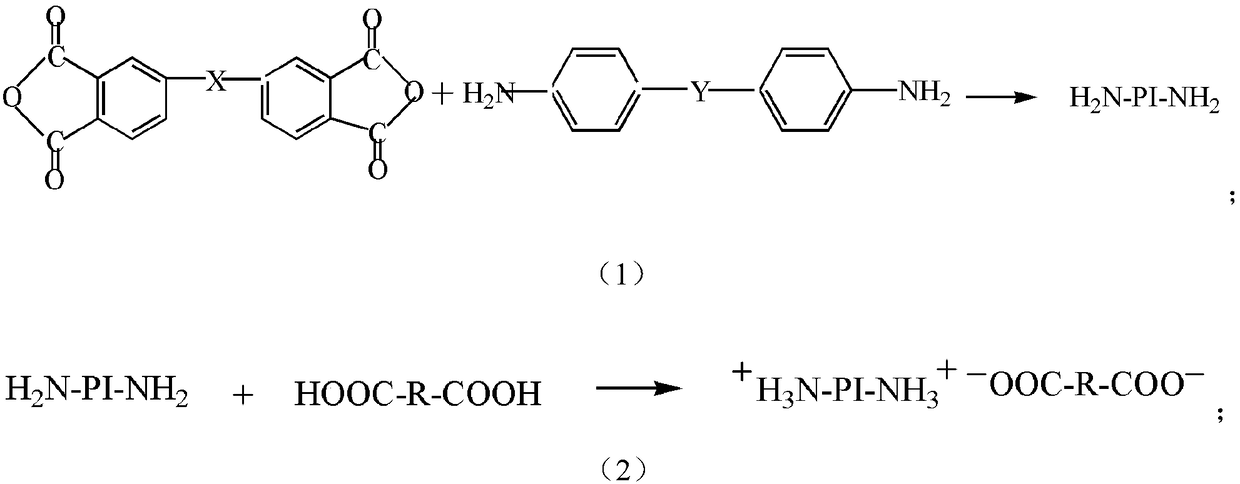

Method used

Image

Examples

Embodiment 1

[0038] A kind of preparation method of polyimide modified nylon 6 of the present invention, comprises the following steps:

[0039] (1) Under the protection of nitrogen, dissolve 4,4'-diaminodiphenyl ether in N,N-dimethylformamide solvent, and then add 4,4'- Oxydiphthalic anhydride and stirring to react to obtain N,N-dimethylformamide solution of polyamic acid, in which 4,4'-diaminodiphenyl ether and 4,4'-oxydiphthalic acid The molar ratio of formic anhydride is 1.5:1, the mass fraction of the total amount of 4,4'-diaminodiphenyl ether and 4,4'-oxydiphthalic anhydride in the system (total mass of diamine, dianhydride and solvent) 15%;

[0040](2) Add m-xylene / pyridine mixed solvent in the N,N-dimethylformamide solution of polyamic acid prepared in step (1) (xylene and pyridine volume ratio are 2:1 in this mixed solvent), Then reflux at 60±5°C for 18 hours to obtain N,N-dimethylformamide solvent of thermoplastic polyimide. After cooling, precipitate with absolute ethanol, fil...

Embodiment 2

[0048] A kind of preparation method of polyimide modified nylon 66 of the present invention, comprises the following steps:.

[0049] (1) is identical with embodiment 1 step (1);

[0050] (2) is identical with embodiment 1 step (2);

[0051] (3) is identical with embodiment 1 step (3);

[0052] (4) Add 0.03mol compound salt I, 15mol adipic acid, 15mol hexamethylenediamine, 20wt% water (the amount of water added accounts for 20wt% of the total mass of compound salt I, adipic acid, hexamethylenediamine and water) In the 10L high-temperature and high-pressure polymerization kettle, nitrogen was replaced three times; then the stirring was started, the temperature inside the kettle was heated to 215°C, the pressure inside the kettle rose to 1.8MPa, and the pressure was maintained for 2 hours; The temperature in the kettle was gradually increased to 280°C; finally, the reaction was continued for 1 hour under the conditions of -0.006MPa and 280°C in the kettle; then the bottom valv...

Embodiment 3

[0056] A kind of preparation method of polyimide modified nylon 610 of the present invention, comprises the following steps:.

[0057] (1) is identical with embodiment 1 step (1);

[0058] (2) is identical with embodiment 1 step (2);

[0059] (3) is identical with embodiment 1 step (3);

[0060] (4) Add 0.03mol compound salt I, 15mol sebacic acid, 15mol hexamethylenediamine, 20wt% water (the amount of water added accounts for 20wt% of the total mass of compound salt I, sebacic acid, hexamethylenediamine and water) In the 10L high-temperature and high-pressure polymerization kettle, nitrogen was replaced three times; then the stirring was started, the temperature inside the kettle was heated to 215°C, the pressure inside the kettle rose to 1.8MPa, and the pressure was maintained for 2 hours; The temperature in the kettle was gradually increased to 270°C; finally, the reaction was continued for 1 hour under the conditions of -0.006MPa and 280°C in the kettle; then the bottom v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com