CRTS II-type ballastless track plate pavement accurate adjustment vehicle

A technology of ballastless track and fine adjustment, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of difficult to realize automatic operation, difficult to realize automation, low adjustment accuracy, etc. high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

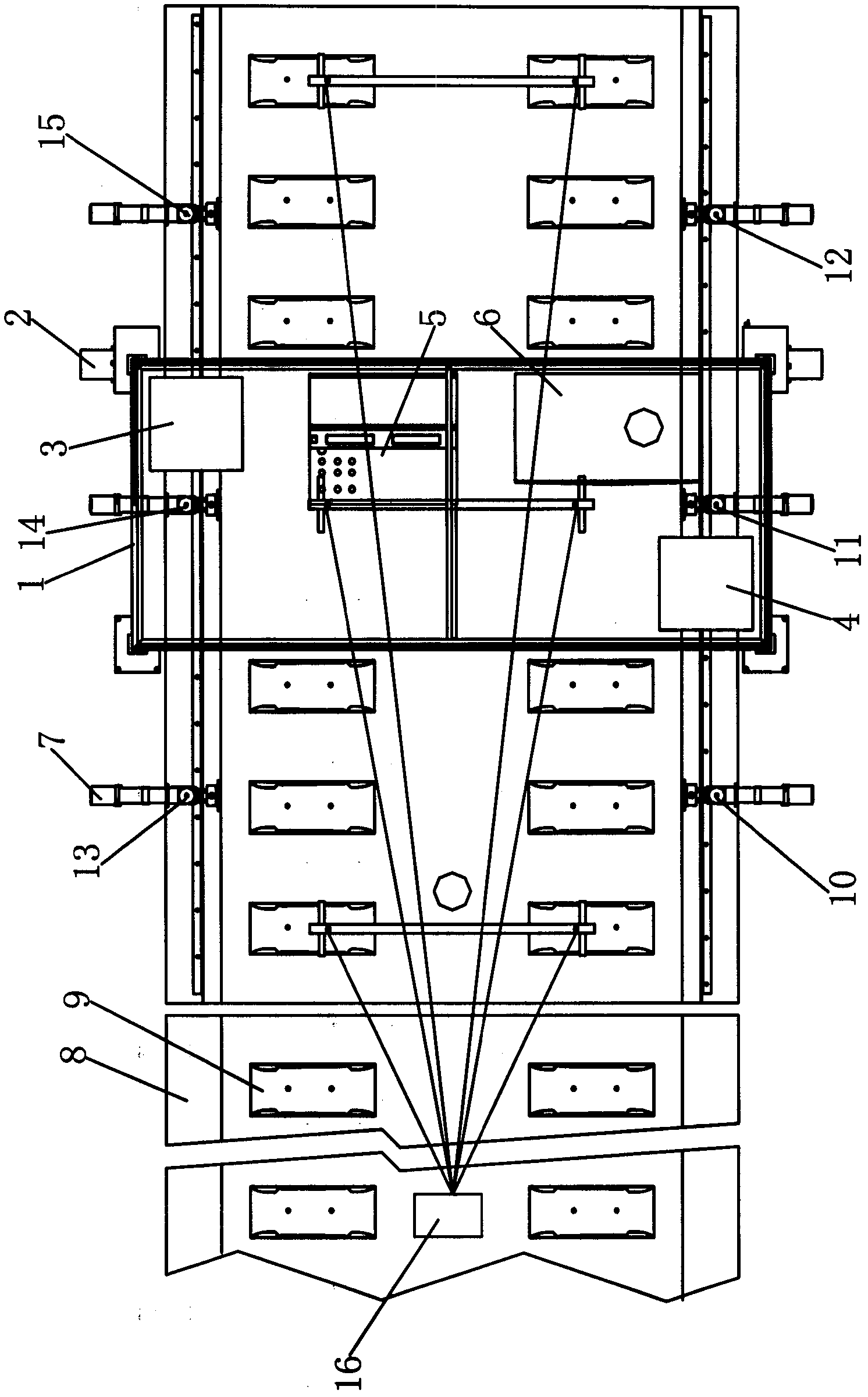

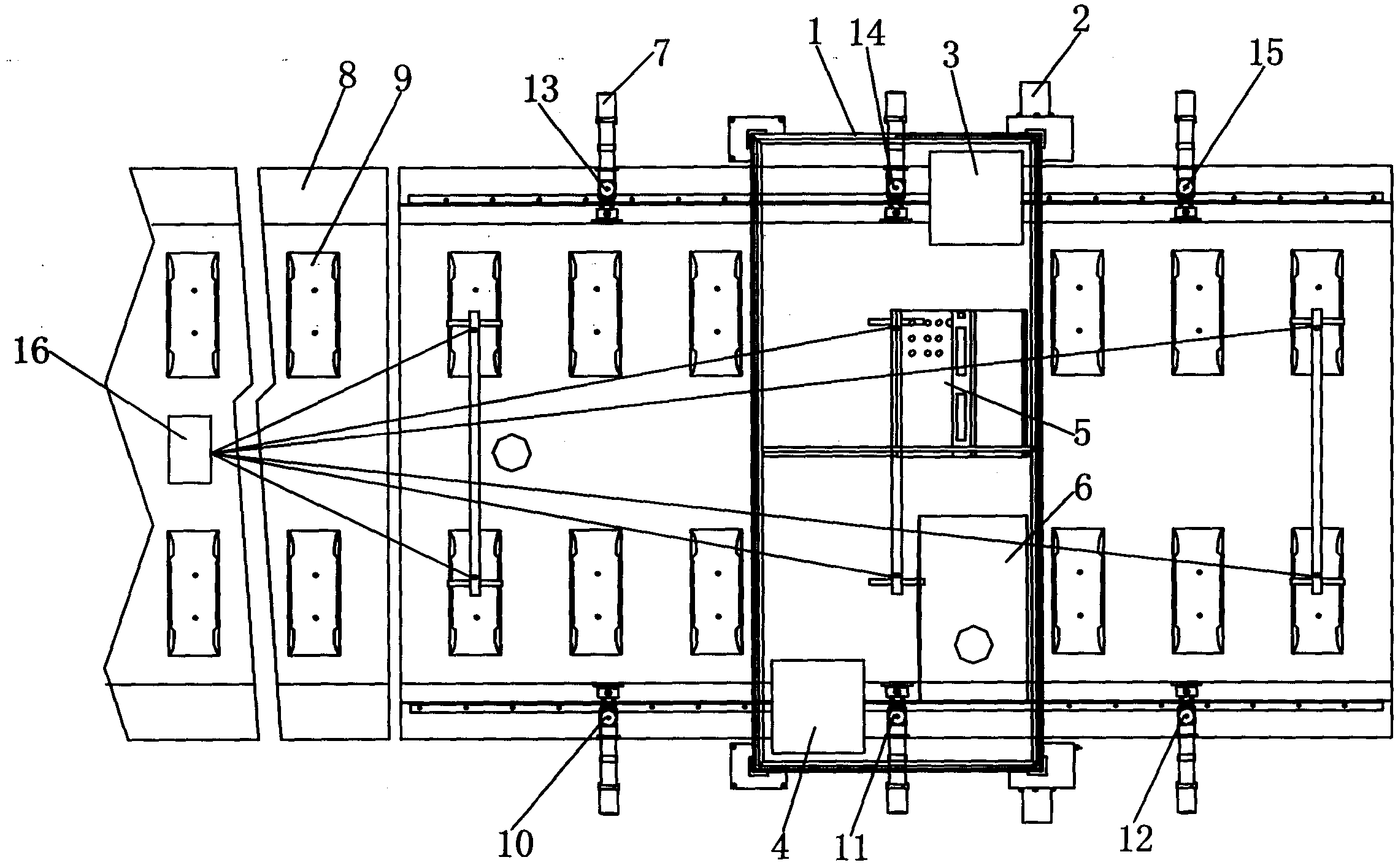

[0017] Such as figure 1 As shown, the CRTS II ballastless track slab laying fine-tuning vehicle consists of two parts, the hood frame and the walking part, and is applied to the automatic and precise adjustment of the CRTS II ballastless track slab. The hood frame is arranged on the walking part, and the walking part includes the walking wheels 2 arranged under the hood frame 1. The four corners of the hood frame are respectively provided with driving wheels, and the two driving wheels at the front end are equipped with drive motors. A hydraulic motor, the hydraulic circuit of the hydraulic motor is provided with a two-way valve for controlling braking; The lower end of the hood frame is provided with a bottom support platform, and the distance between the bottom support beam and the upper surface of the rail platform 9 of the ballastless track slab 8 is greater than 65 cm, and the ballastless track slab 8 is arranged on the foundation. Two fine-tuning mechanism storage boxes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com