CRTS III ballastless track slab layering fine tuning vehicle

A ballastless track, fine-tuning technology, applied in tracks, track laying, track maintenance, etc., can solve the problems of difficult to achieve automatic operation, difficult to achieve automation, many operators, etc., to achieve complete functions, fewer operators, and adjustment. high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

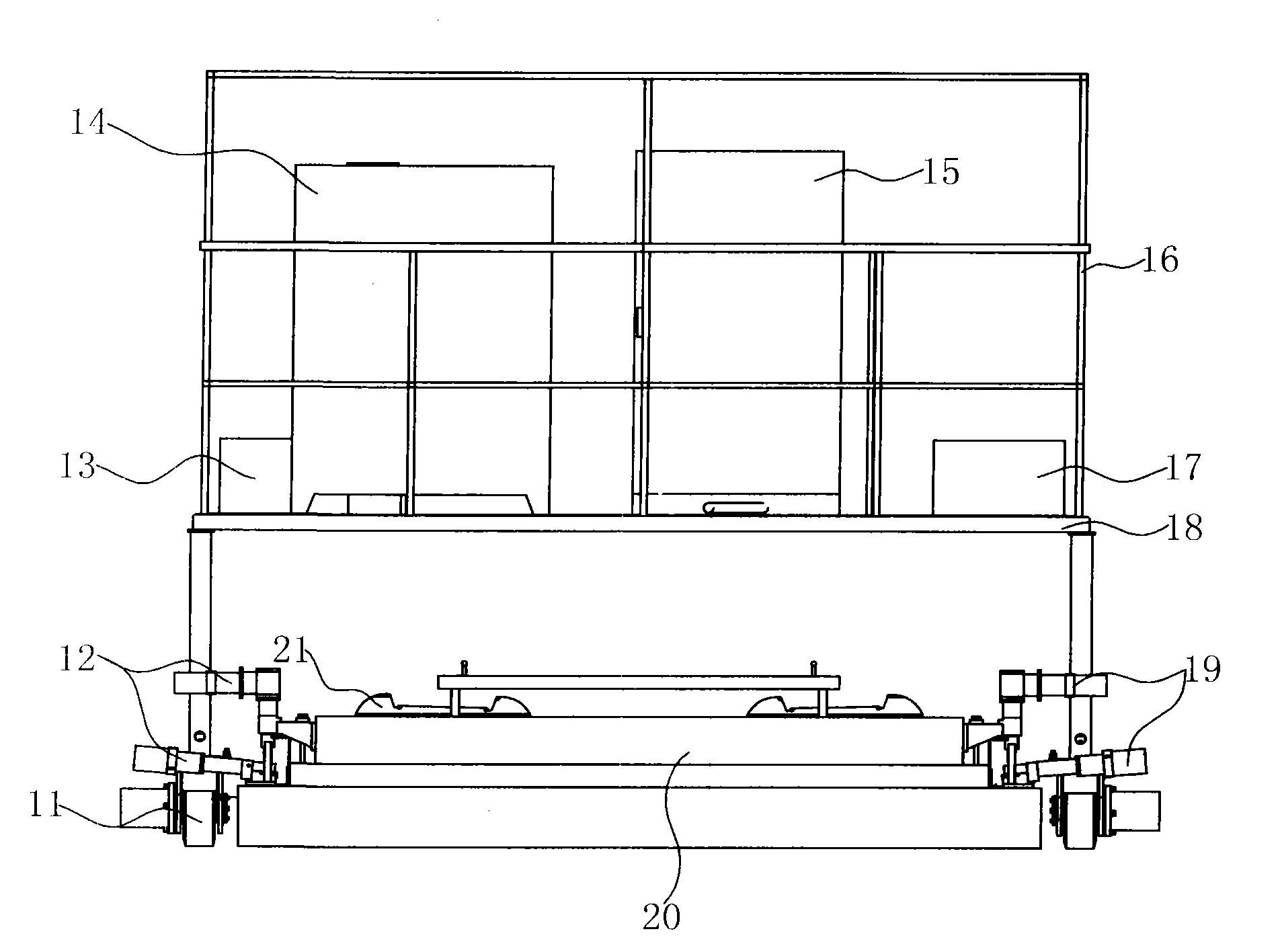

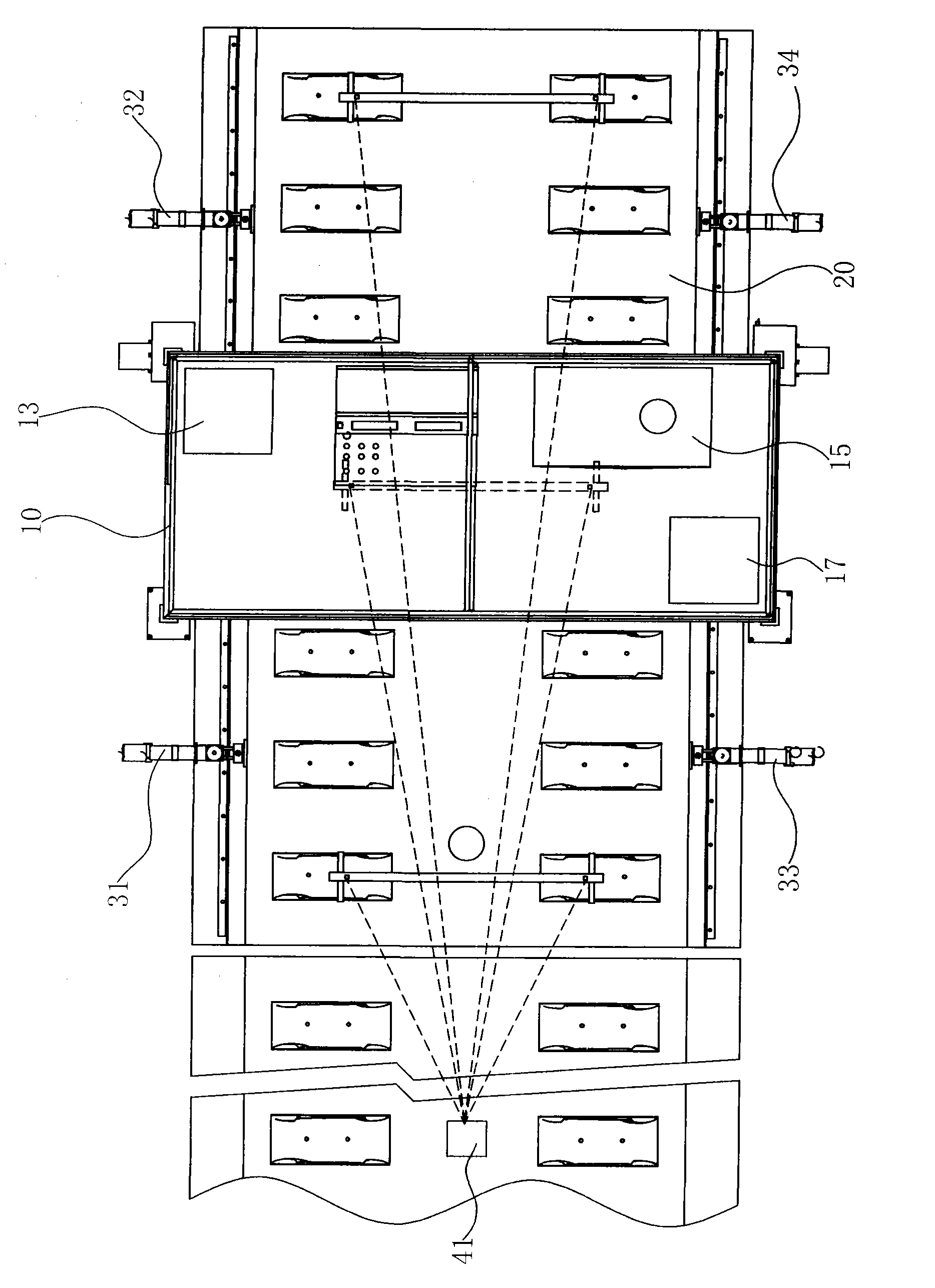

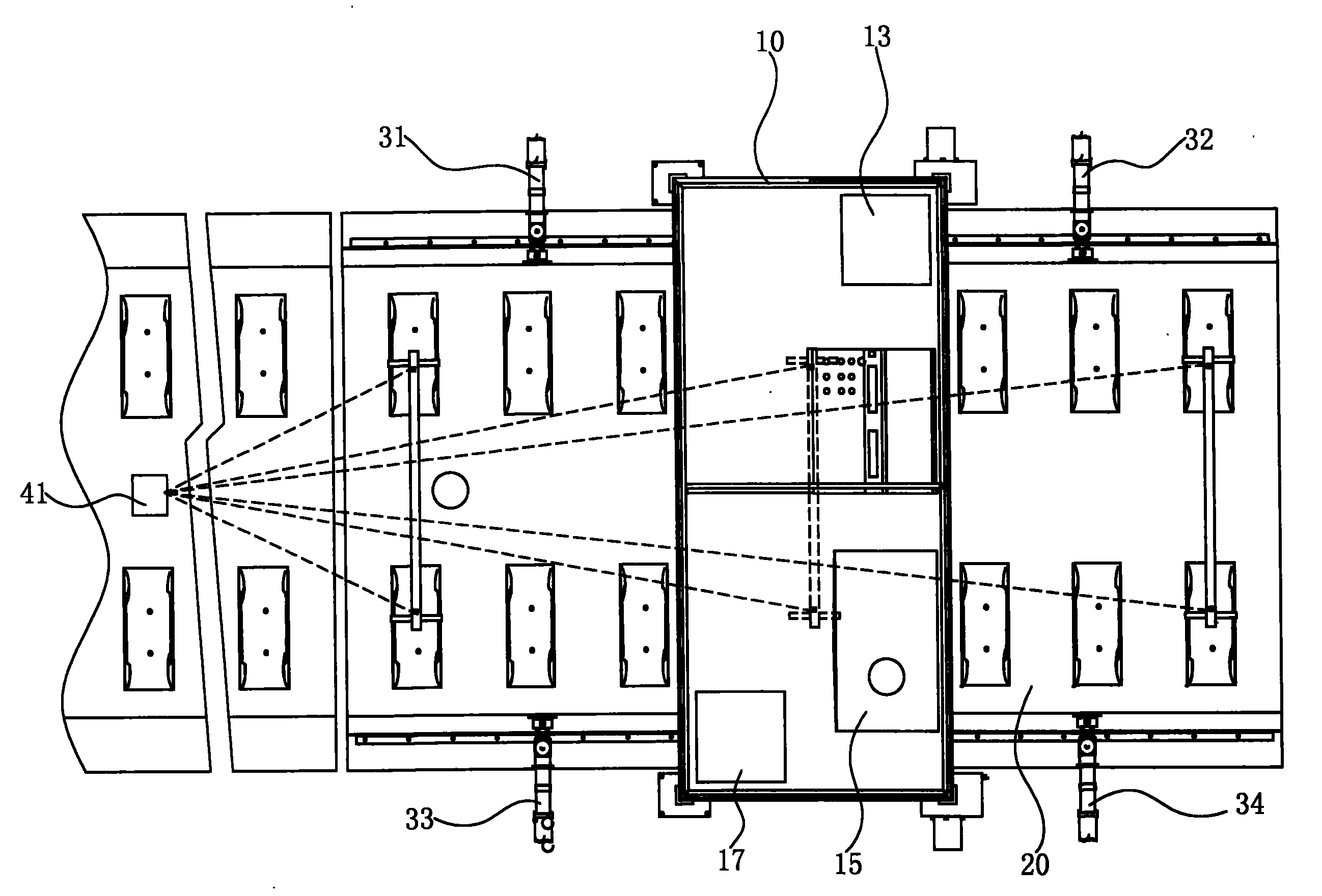

[0019] Such as figure 1 and figure 2 As shown, the CRTSIII type ballastless track slab laying fine-tuning car mainly includes a hood frame and a walking part, and a bearing plate 18 is arranged on the hood frame, and the fine-tuning mechanism storage boxes 13, 17 and The walking part of the industrial computer 14 includes traveling wheels 11 arranged at four corners below the frame, wherein the two traveling wheels at the front end are connected with a driving mechanism. The axles of the two walking wheels are equipped with hydraulic motors (or motors and reducers) to control the walking of the automatic adjustment mechanism, and a two-way valve is installed on the hydraulic circuit to control the braking of the automatic adjustment mechanism. In addition, one or more sets of side limit wheel mechanisms are respectively arranged in the middle part of both sides of the fine-tuning vehicle to play a guiding role.

[0020] Two fine adjustment mechanism storage boxes 13, 17 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com