Gas sensor chip as well as manufacturing method and measuring system thereof

A technology of a gas sensor and a manufacturing method, which is applied in the direction of electrochemical variables of materials, etc., can solve the problems of difficulty in the preservation of the activity of the active layer, and achieve the effects of improving production efficiency and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

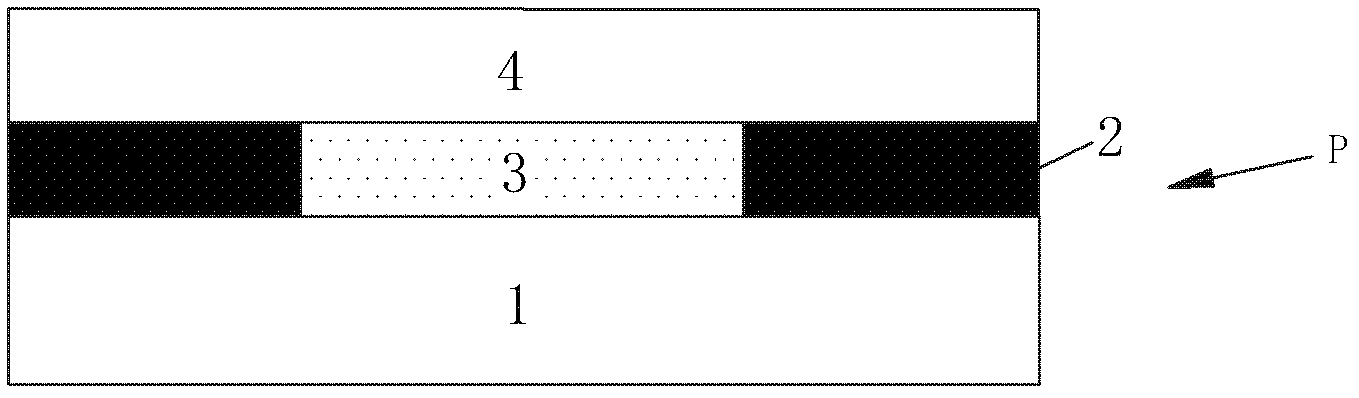

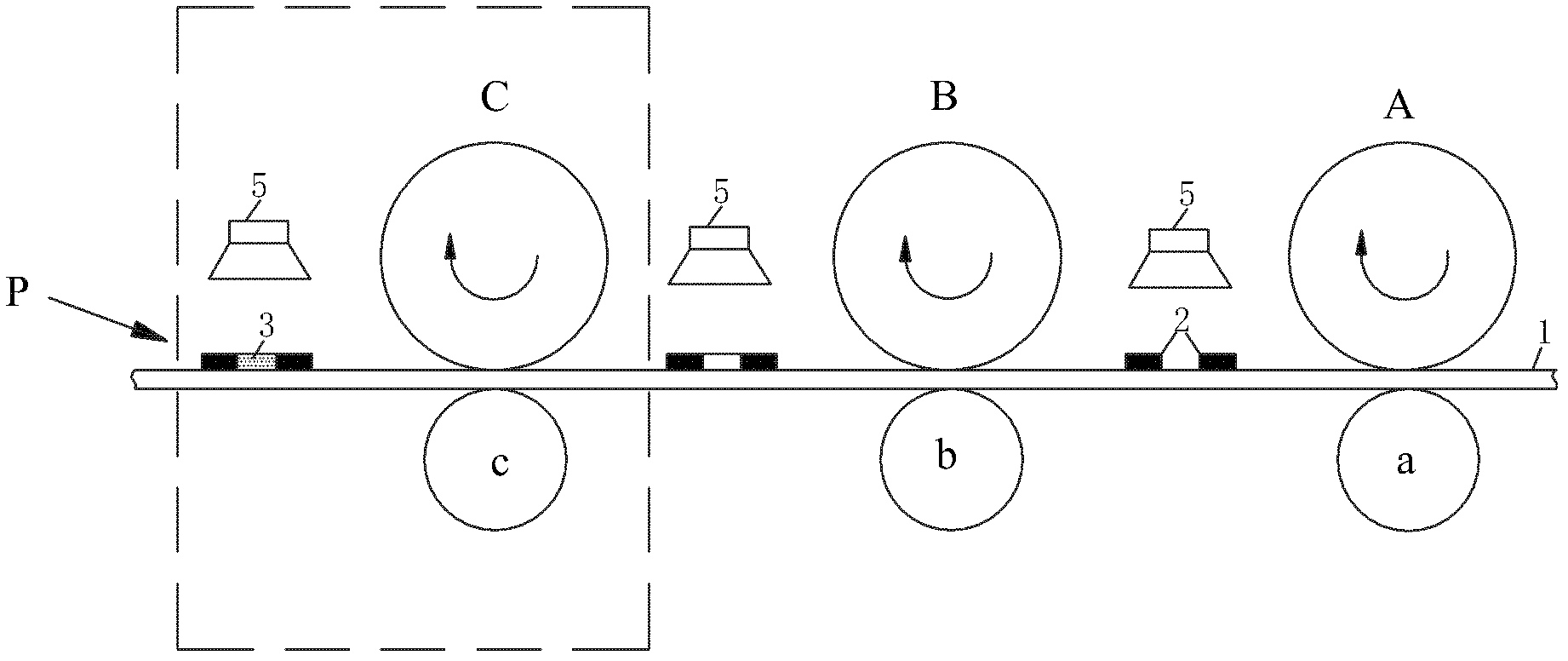

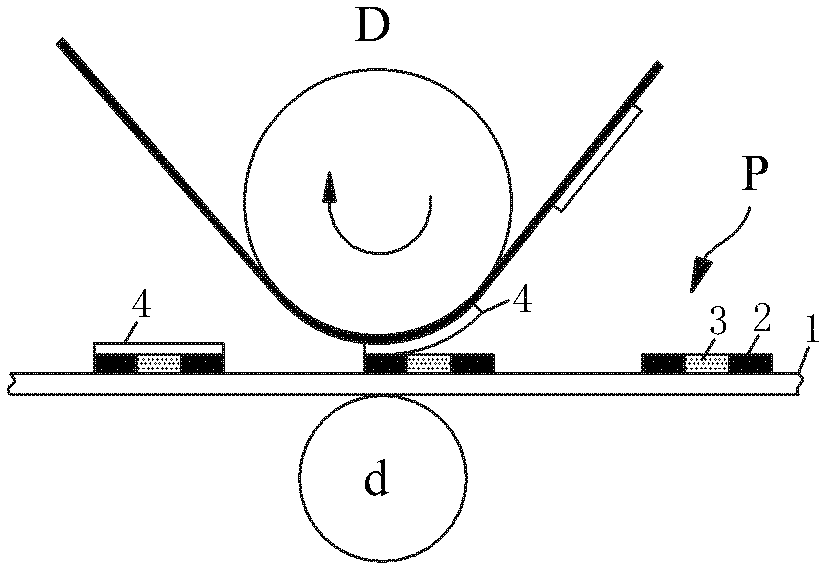

[0045] Sensor chip P for testing food freshness

[0046] Food safety is a major issue related to the national economy and the people's livelihood, and eating food before it spoils is the safest way of consumption. Because food contains a lot of amino acids and proteins, ammonia gas will be emitted when the food is spoiled. The detection of ammonia gas is also a relatively simple method to detect the freshness of food. The modern way of serving food is generally to serve food in plastic film. Among them, the flexible substrate 1 of this embodiment is made of polyimide (PI), and the flexible electrode pair 2 is made with 1.3% PEDOT ink according to the above method, and the concentration of organic polythiophene is 5 mg / ml, and the concentration is 15 mg / ml P-type dopant material NOPF 6 Make the sensing layer 3, and then print each device on the surface of the flexible substrate 1 according to the method for making the gas sensor chip P of the present invention, so as to o...

Embodiment 2

[0048] Sensor chip P for testing food freshness

[0049] The flexible substrate 1 of this embodiment is made of polyimide (PI), and the flexible electrode pair 2 is made of 1.5% PEDOT:PSS ink according to the above method, and the concentration is 8 mg / ml organic polythiophene, and the concentration is 18 mg / ml P-type dopant material NOPF 6 Make the sensing layer 3, then according to the manufacturing method of the gas sensor chip P of the present invention, print each device on the surface of the flexible substrate 1 in turn, obtain the gas sensor chip P that can judge the freshness of food according to the measurement of ammonia gas, When there is doubt about the freshness of the food, the protective film 4 of the gas sensor chip P is removed, and the measuring electrode pair 11 is placed on the flexible electrode pair 2 of the gas sensor chip P. If the food emits ammonia gas, the ammonia gas will interact with the sensing layer 3 of the gas sensor chip P, increasing th...

Embodiment 3

[0051] The flexible substrate 1 of this embodiment is made of polyimide (PI), and the flexible electrode pair 2 is made with 1.7% PEDOT:PSS ink according to the above method, and the concentration is 10 mg / ml organic polythiophene, and the concentration is 20 mg / ml P-type dopant material NOPF 6 Make the sensing layer 3, then according to the manufacturing method of the gas sensor chip P of the present invention, print each device on the surface of the flexible substrate 1 in turn, obtain the gas sensor chip P that can judge the freshness of food according to the measurement of ammonia gas, When there is doubt about the freshness of the food, the protective film 4 of the gas sensor chip P is removed, and the measuring electrode pair 11 is placed on the flexible electrode pair 2 of the gas sensor chip P. If the food emits ammonia gas, the ammonia gas will interact with the sensing layer 3 of the gas sensor chip P, increasing the resistance of the sensing layer 3, which reduces t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com