Temperature rise strain monitoring and alarming and fault analysis method for composite submarine cable

A fault analysis method and strain monitoring technology, applied in the fault location and other directions, can solve problems such as failure to locate the fault location, abnormal temperature rise of submarine cables, lack of monitoring measures for stress and deformation, and unpredictable safety status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

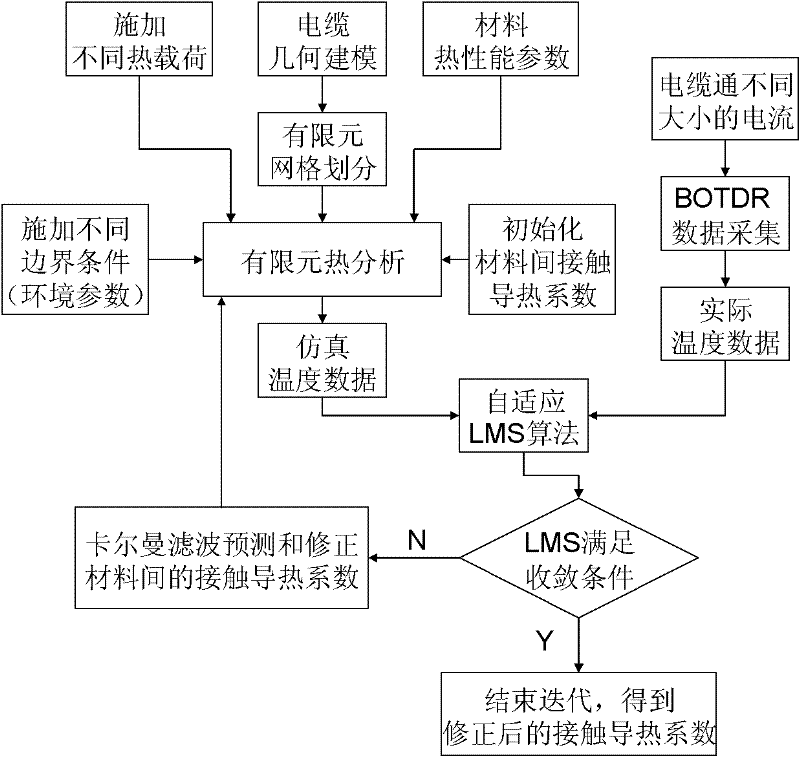

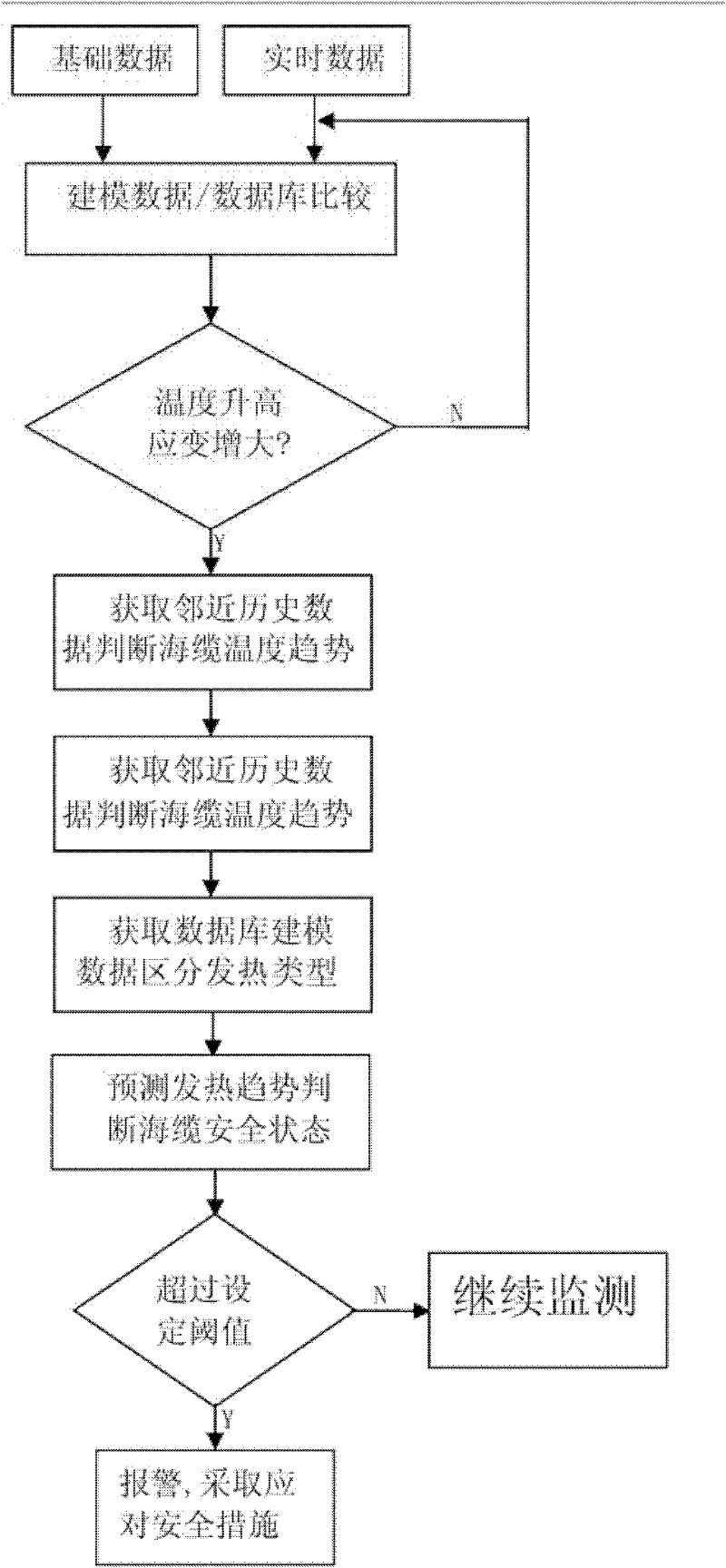

[0054]The composite submarine cable includes power cables and single-mode communication optical fibers. The power cables are used for power transmission between oil production platforms, and the single-mode optical fibers realize long-distance communication. When manufacturing submarine cables, the number of communication optical fibers generally has a margin of 20%. The invention utilizes redundant single-mode optical fibers for temperature stress sensing, and evaluates the safety status of composite submarine cables in combination with power harmonic test parameters.

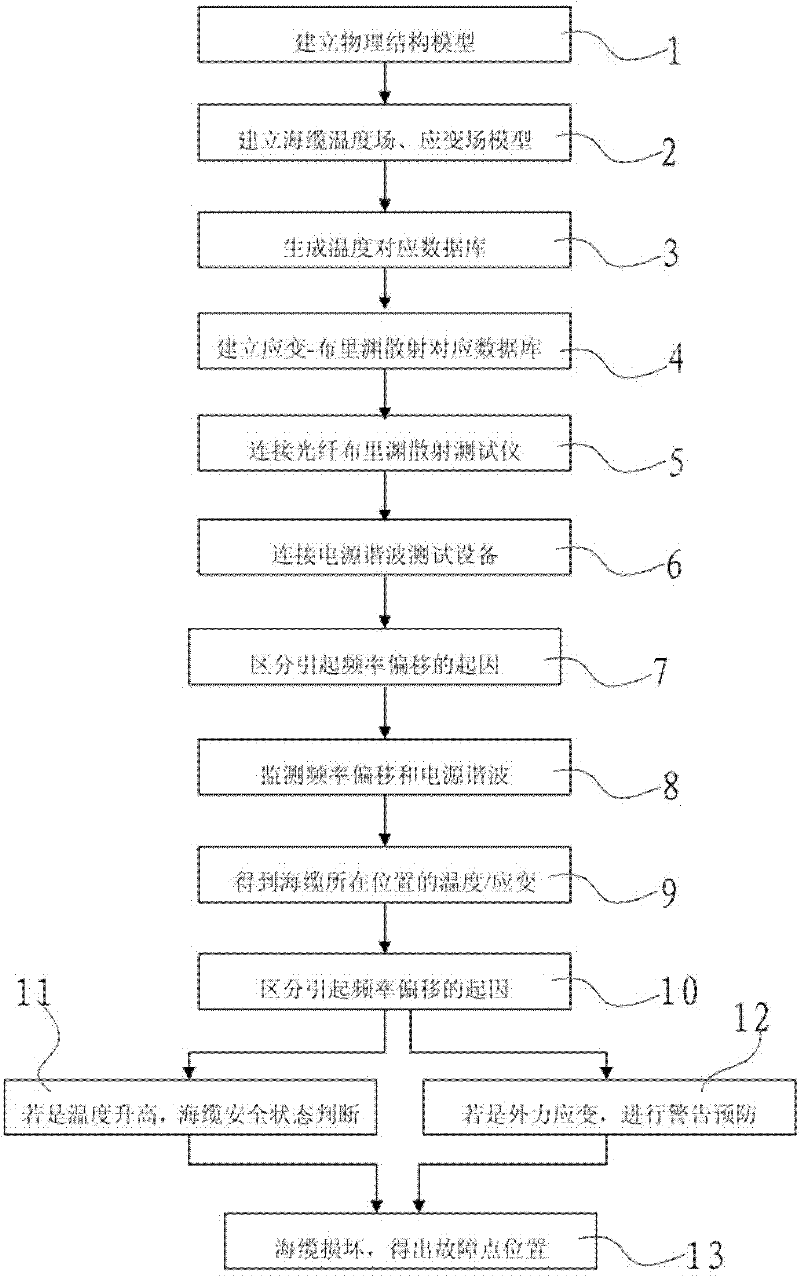

[0055] Based on the above principles, the specific implementation of the present invention is as follows (see figure 1 ):

[0056] 1. Obtain the physical structure size of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com