Driving apparatus of sensorless brushless motor

A technology for brushless motors and drive equipment, applied in the direction of AC motor control, electronic commutation motor control, single motor speed/torque control, etc., can solve the problems of complex circuit design, high cost, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

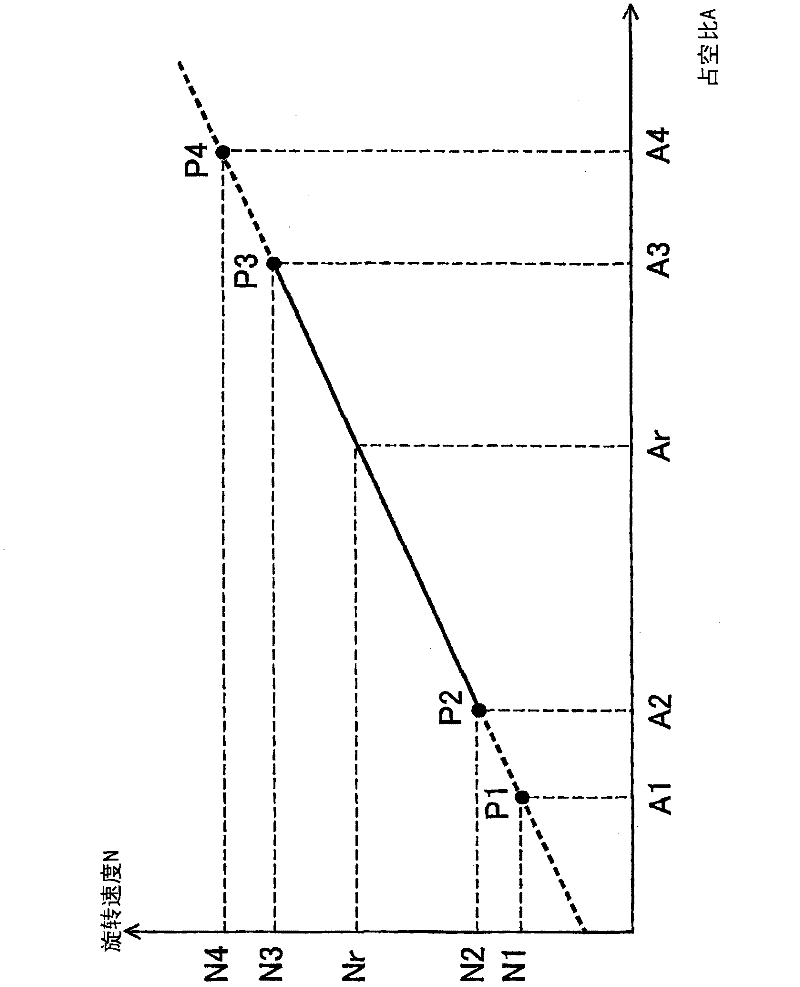

[0043] For the purpose of describing an embodiment of the sensorless brushless motor 9 driving device 1 according to the present invention, the length of time during which the power supply voltage Vcc is supplied within one PWM frequency cycle is referred to as an operation period. The length of time for which the power supply voltage Vcc is continuously supplied to a predetermined phase with a plurality of operation periods higher than or close to 120 electrical degrees is referred to as a power-on time zone. Generally speaking, the working period is much shorter than the power-on time zone.

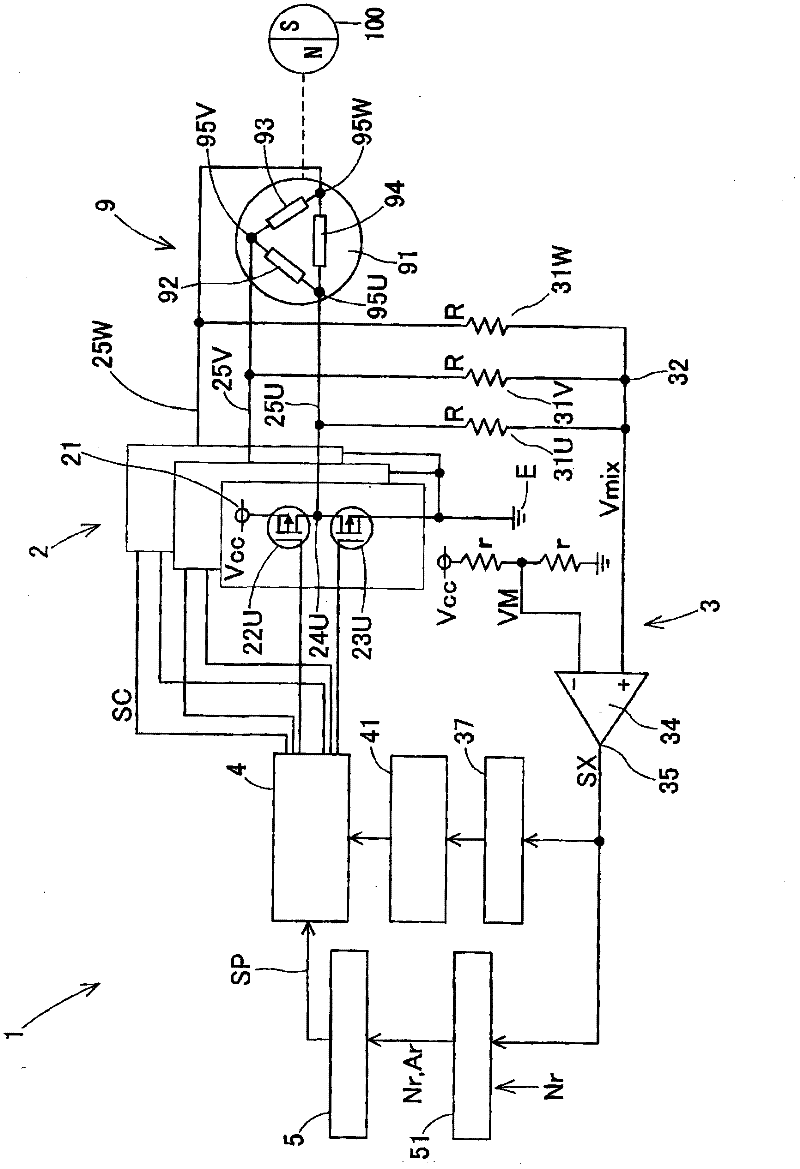

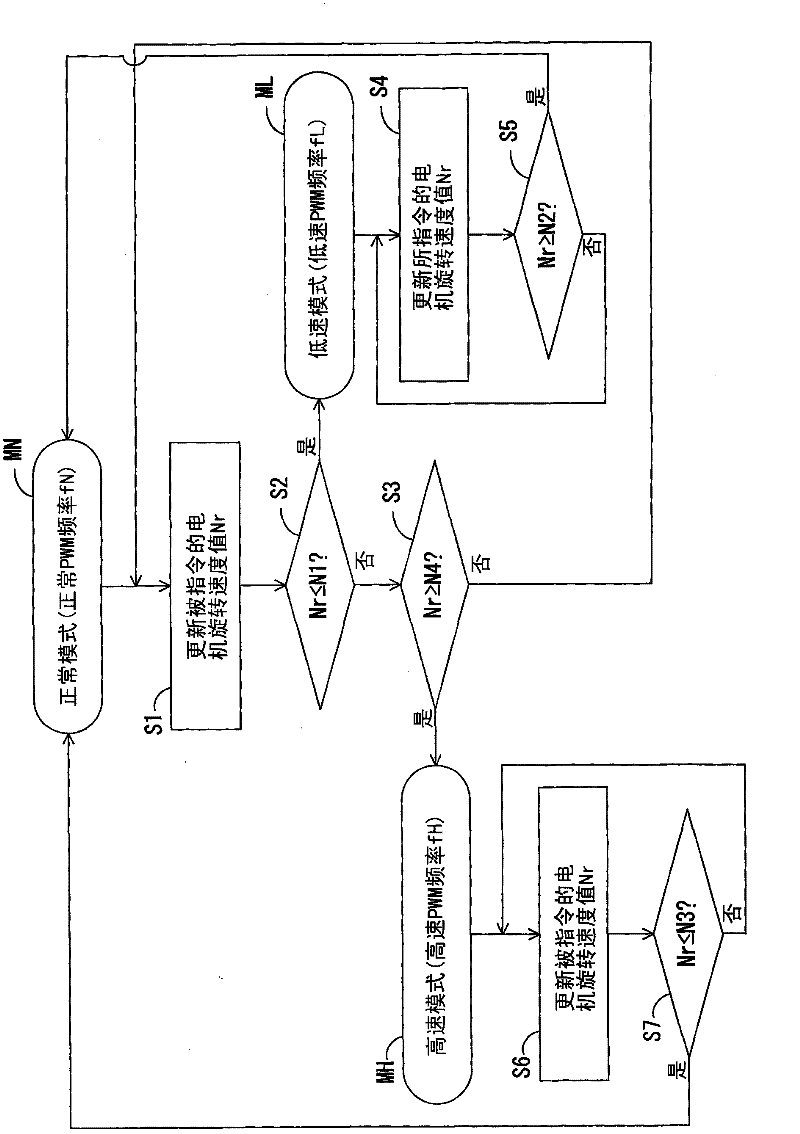

[0044] will refer to figure 1 The configuration and driving operation of the driving device 1 of the sensorless brushless motor 9 according to the first embodiment are described to FIG. 5 . Configure as figure 1 The drive device 1 shown powers up a sensorless brushless motor 9 by using an inverter circuit 2 in which the duty ratio of a power supply voltage is changed by a PWM (Pulse W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com