Control system and control method for automatic gear shifting of loader

A control method and automatic transmission technology, which is applied to earth movers/excavators, construction, etc., can solve the problem of not considering the impact of machine efficiency, not considering the traction demand of loaders, and unable to ensure continuous power when shifting gears sexual issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0053] The specific embodiment of the present invention is as follows:

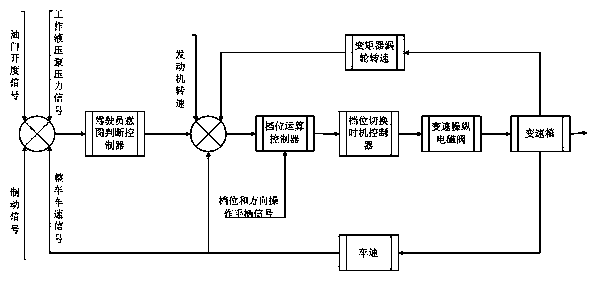

[0054] The control system includes:

[0055] The driver's intention recognition controller is used to detect the vehicle speed, accelerator opening, working hydraulic pump pressure and vehicle braking signal, and use fuzzy algorithm and threshold value comparison method to calculate the category of driver's intention;

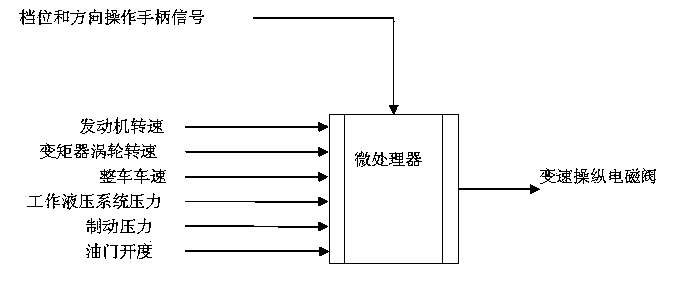

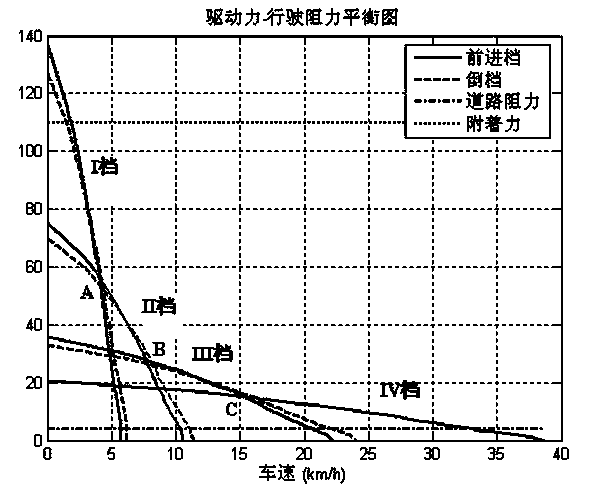

[0056] The target gear calculation controller is used to detect the vehicle speed, shift and direction joystick signals, the torque converter turbine speed and receive the driver's intention signal, and combine the driver's intention category calculated by the driver's intention recognition controller, Use the optimal power shift algorithm, the optimal torque converter efficiency shift algorithm and the corresponding shift strategy to calculate the target gear;

[0057] The gear switching timing controller is used to receive the signal output by the target gear calculation controller, use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com