Torque buffering device capable of being elastically compressed by multiple circles for mechanical transmission

A mechanical transmission and elastic compression technology, which is applied in the direction of transmission control, mechanical equipment, and components with teeth, etc., can solve the problems of increasing the size of gears and transmission shafts, breaking teeth or transmission shafts, and increasing safety factors. Achieve the effect of increased vehicle weight, increased volume, and reduced torque impact value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

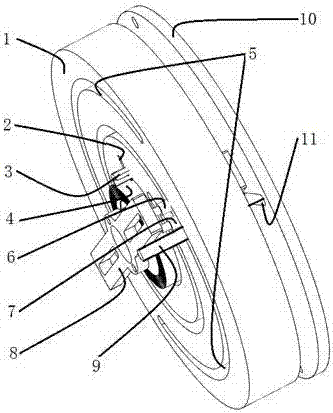

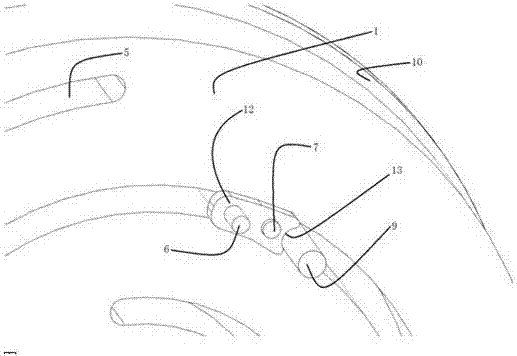

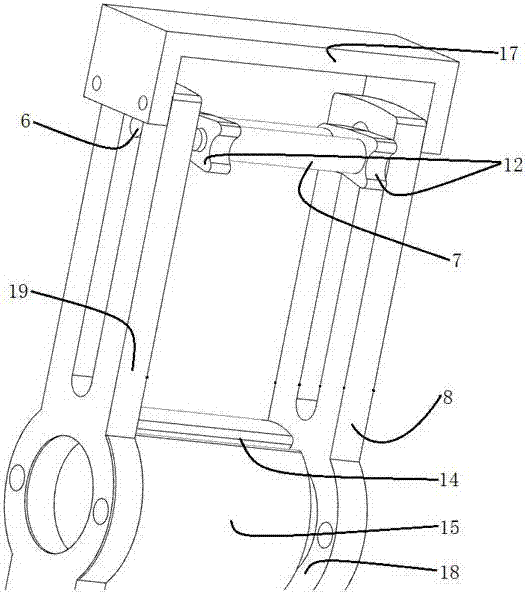

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0025] The invention provides a second-speed gear transmission suitable for transmissions of internal combustion engine vehicles and new energy vehicles, buffer transmission of clutch output shafts, input shafts or second-speed gear transmissions of dual-clutch automatic transmissions, and hydraulic transmission of hydraulic-mechanical automatic transmissions. The output shaft of the torque converter or the second gear transmission, the input shaft of the electronically controlled mechanical automatic transmission or the second gear transmission, the transmission transmission of industrial and mining machinery or agricultural machinery, which can shorten the shift time while realizing buffering, making the transmission intermittent The time is shortened to achieve the purpose of smoother transmission.

[0026] As a specific embodiment of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com