Three-channel ABS (anti-locked braking system)

An ABS system, three-channel technology, applied in the field of ABS system, can solve the problems of low performance of ABS system, increased maintenance cost, tire wear, etc., to achieve the effect of compact structure, prolong service life, and reduce wheel wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

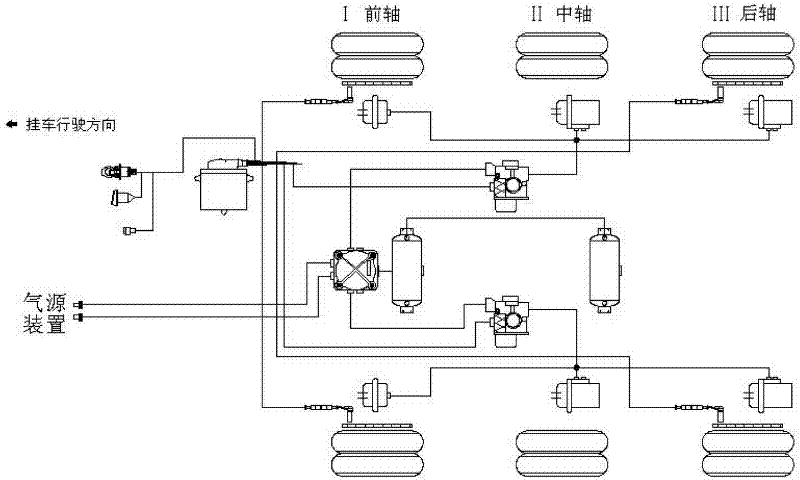

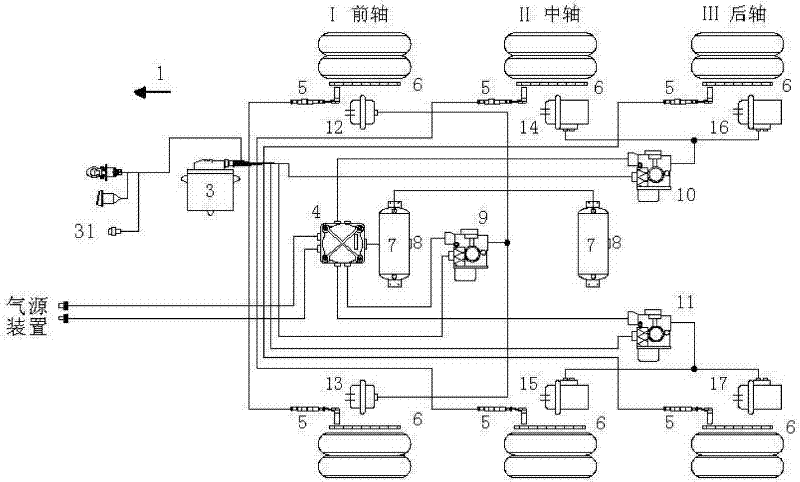

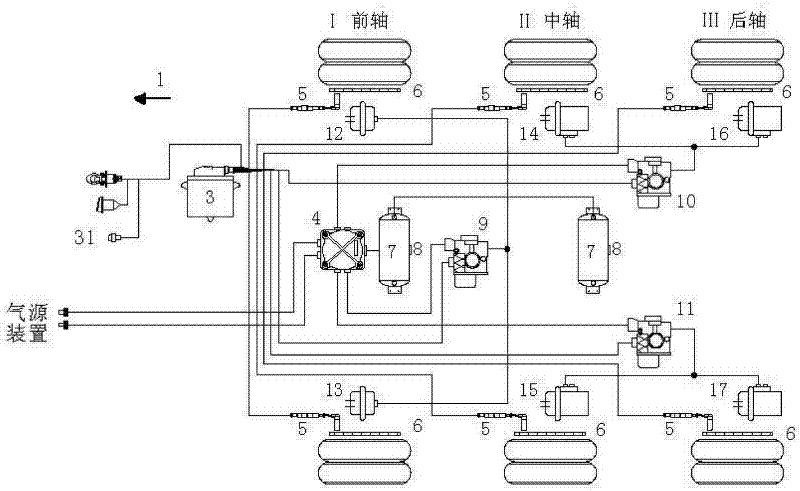

[0018] refer to figure 2 , a three-channel ABS system applied to a three-axle semi-trailer, figure 2 The direction indicated by the middle arrow 1 is the driving direction of the trailer, and the three-axle semi-trailer includes a front axle I, a middle axle II and a rear axle III. In the present invention, ring gears 6 and corresponding ABS wheel speed sensors 5 are installed on the wheels on both sides of the front axle I, middle axle II and rear axle III. figure 2 The ABS wheel speed sensors 5 at the six wheels are all connected to the ABS electronic control unit 3, and the ABS electronic control unit 3 will receive the wheel speed signals of each wheel detected by the ABS wheel speed sensor 5, and the ABS electronic control unit 3 is also connected to There are separate control units for controlling the air intake volume of each wheel brake chamber.

[0019] refer to figure 2 , the control unit includes a first ABS solenoid valve 9, a second ABS solenoid valve 11 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com