Hot rolling container steel without punctiform surface defect and manufacturing method thereof

A manufacturing method and container technology are applied in the field of steel smelting and rolling, which can solve the problems of willow leaf shape, billet waiting to be warmed, spot shape, willow leaf shape surface defects, etc., and achieve the effect of reducing segregation and reducing penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with specific embodiment the present invention is described in further detail:

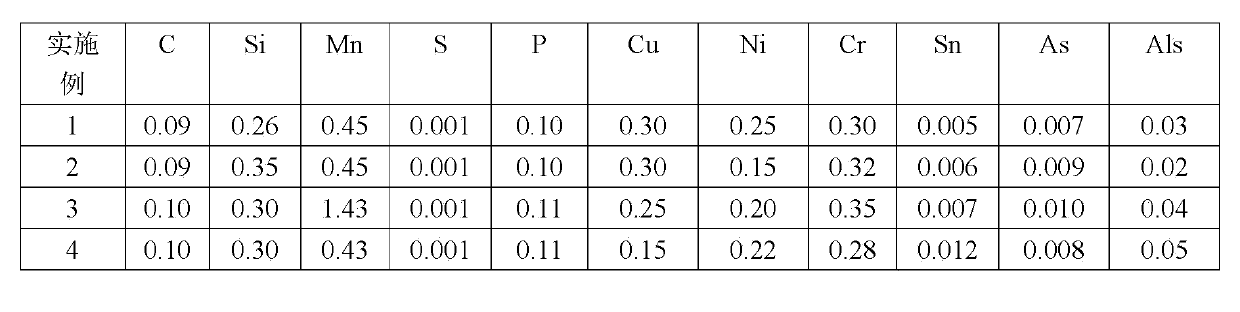

[0023] A hot-rolled container steel without point surface defects, characterized in that the components of the hot-rolled container steel are: C: 0.05-0.20, Si: 0.05-1.00, Mn: 0.2-2.0, P: 0.05~0.20, Cu: 0.05~0.60, Cr: 0.20~0.80, Ni: 0~0.60, S: ≤0.010, Als: 0.015~0.060, Sn≤0.020%, As≤0.020%, the rest are iron and Avoid impurities.

[0024]In the above technical solution, the ratio of Ni to Cu≥0.2, the ratio of Sn to Cu≤0.12, and the ratio of As to Cu≤0.10. Ensuring that the ratio of Ni to Cu ≥ 0.2 can significantly reduce the segregation of Cu at the interface between the oxide scale and the substrate and the penetration into the substrate. Ensuring that the ratio of Sn to Cu ≤ 0.12, and the ratio of As to Cu ≤ 0.10 can reduce the segregation of residual elements, and make the melting point of alloys enriched in residual elements enriched in the interface at a higher t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com