Circumferential Feed Cone Friction Mechanical Clutch

A mechanical clutch and circular feed technology, applied in the field of mechanical parts manufacturing, can solve the problems of long processing cycle, not completely solving the fundamental problems of ball valves, and low efficiency, and achieve large transmission force, shortened intermittent time, and large contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

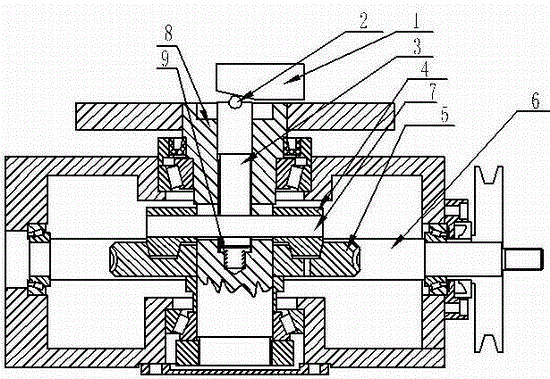

[0013] exist figure 1 The structure diagram of the circular feed cone friction mechanical clutch shown in the figure, its main structure includes: the inclined surface of the wedge block 1 is in contact with the movable steel ball 2, the small shaft 3 is arranged at the lower part of the movable steel ball 2, and the dynamic clutch 4 is provided with The outer conical surface 10 of the dynamic clutch and the inner conical surface 11 of the static fixed clutch are arranged on the static fixed clutch 5, the outer conical surface 10 of the dynamic clutch and the inner conical surface 11 of the static fixed clutch are closely fitted, and the worm 6 is connected with the dynamic clutch 4 through the worm wheel, The dynamic clutch 4 is connected with the pin shaft 7, and the pin shaft 7 is connected with the main shaft 8, and a spring 9 is arranged at the bottom of the dynamic clutch 4.

[0014] The working principle of the present invention: the wedge 1 moves forward under the acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com