Planet row and assembly process thereof

A technology of planetary row and planetary carrier, which is applied in the field of power transmission device for transmission, planetary row and its assembly process, which can solve the problems that the planetary row cannot bear, takes up a large space, and large axial load, etc., and achieves convenient processing and compact structure , The effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

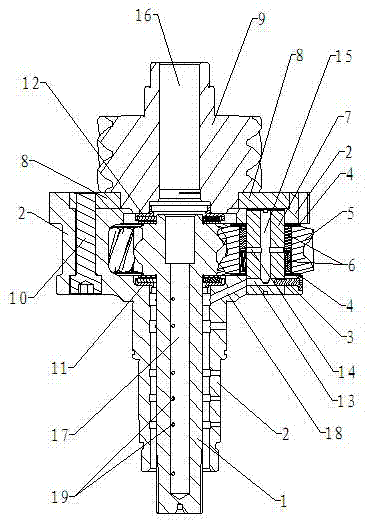

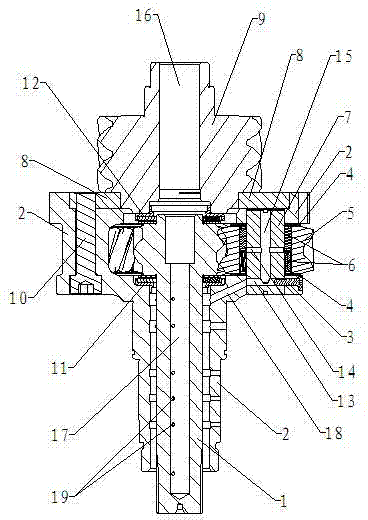

[0041] Example 1, such as figure 1 As shown, a planetary row includes a sun gear 1, a planet gear 5 and a planet carrier 2, the sun gear 1 is set in the cavity of the planet carrier 2, the planet gear 5 is supported on the planet carrier 2, and the sun gear 1 is close to the input A first thrust bearing 11 is provided between the end surface of the end and the planet carrier 2; a second thrust bearing 12 is provided on the end surface of the sun gear 1 close to the output end; the outer surfaces of the first thrust bearing 11 and the second thrust bearing 12 The radius of the circle is greater than the minimum distance from the tooth top of the planetary gear 5 to the center line of the planetary carrier 2; the output end of the sun gear 1 is coaxially connected with a gear 9, and the second thrust bearing 12 is arranged between the gear 9 and the sun gear 1; the gear 9 It is fixedly connected with the planetary carrier 2; the gear 9 is fixedly connected with a connecting disc...

Embodiment 2

[0051] Example 2, such as figure 1 As shown, a planetary row includes a sun gear 1, a planet gear 5 and a planet carrier 2, the sun gear 1 is set in the cavity of the planet carrier 2, the planet gear 5 is supported on the planet carrier 2, and the sun gear 1 is close to the input A first thrust bearing 11 is provided between the end surface of the end and the planet carrier 2; a second thrust bearing 12 is provided on the end surface of the sun gear 1 close to the output end; the outer surfaces of the first thrust bearing 11 and the second thrust bearing 12 The radius of the circle is greater than the minimum distance from the tooth top of the planetary gear 5 to the center line of the planetary carrier 2; the output end of the sun gear 1 is coaxially connected with a gear 9, and the second thrust bearing 12 is arranged between the gear 9 and the sun gear 1; the gear 9 It is fixedly connected with the planetary carrier 2; the gear 9 is fixedly connected with a connecting disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com