Automatic shifting target for artillery

A moving target and automatic technology, applied in the direction of movable targets, targets, offensive equipment, etc., can solve the problems of difficult installation quality assurance, heavy artillery targets, difficult target movement, etc., and achieve short installation time, high degree of automation, and easy operation. high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the embodiments shown in the drawings.

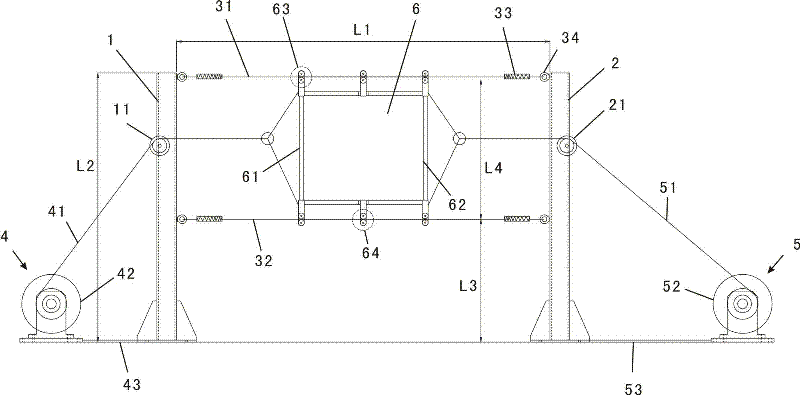

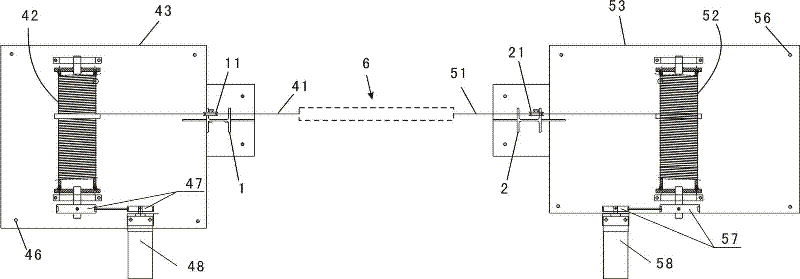

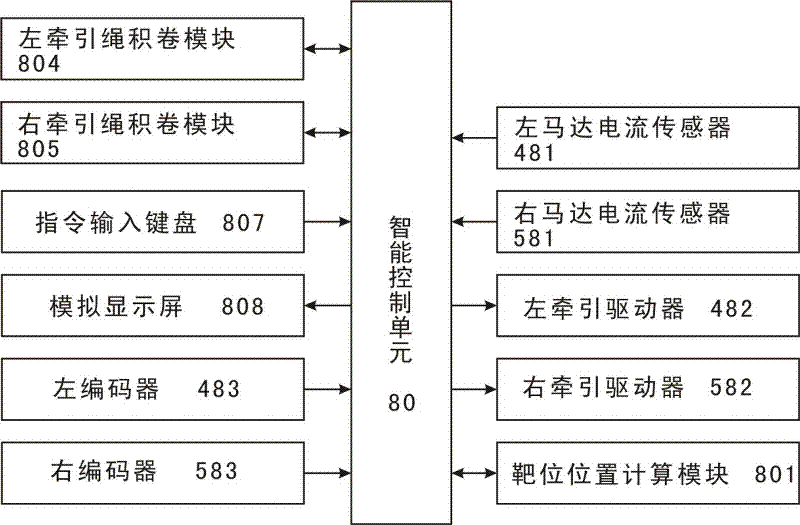

[0048] Such as Figure 1 ~ Figure 3 As shown, an artillery automatic displacement target is designed and manufactured, and its structure includes:

[0049] A left support rod 1, a right support rod 2, the left support rod 1 is provided with two pull rings 34 up and down; the right support rod 2 is provided with two pull rings 34 up and down;

[0050] Between the two upper pull rings, an upper steel rope 31 is used to fix it, and the two ends are tightened with a rope tightener 33;

[0051] A steel rope 32 is placed between the two pull-down rings to fix it, and the two ends are tightened with a rope tensioner 33;

[0052] A target 6, the target 6 has more than one upper pulley group 63, and the upper steel rope 31 passes through each upper pulley group 63;

[0053] And more than one lower pulley group 64, the lower steel rope 32 passes through each lower pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com