A device for installing bearings of motor of washing machine

A technology of motor bearings and washing machines, which is applied in the direction of electromechanical devices, manufacturing motor generators, casings/covers/supports, etc., can solve problems such as instability, affecting motor quality, and small motor size, and achieve force balance and installation Good effect, good force transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

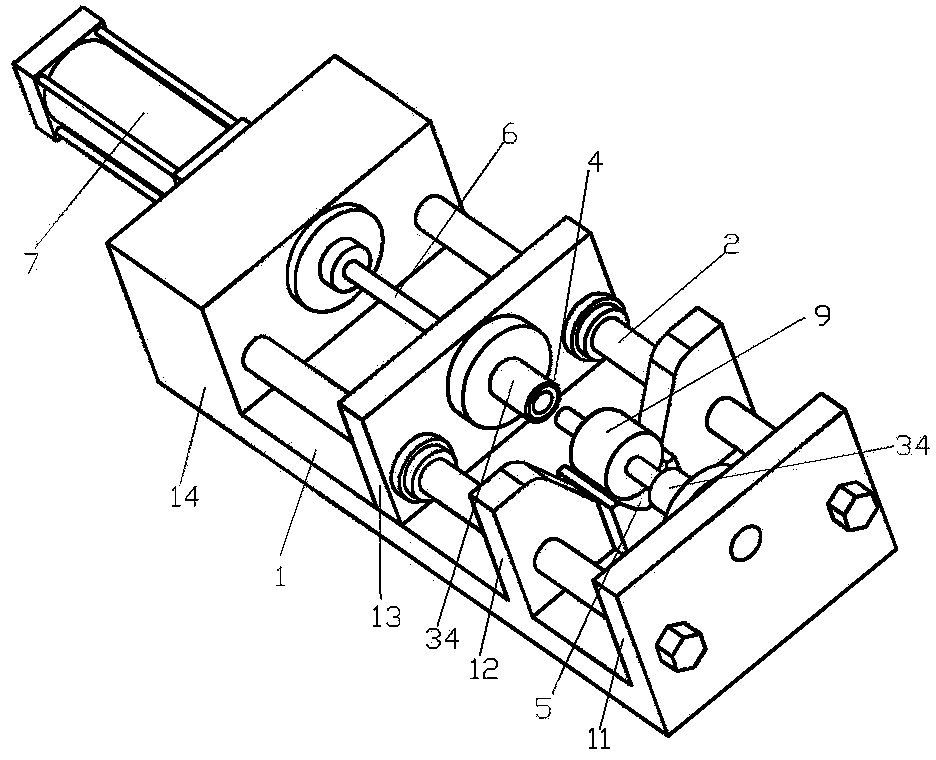

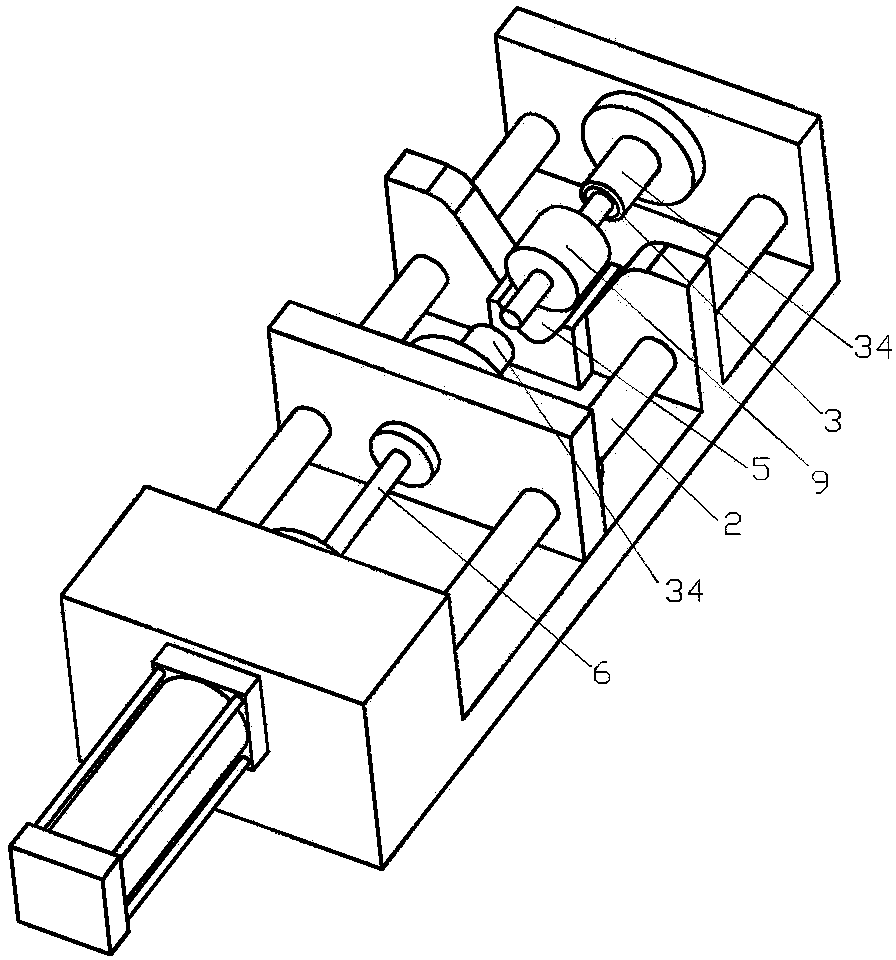

[0018] Example 1, such as figure 1 , 2 As shown, a device for installing the bearings of washing machine motors includes a bottom plate 1. The bottom plate 1 is provided with a head plate 11, a positioning plate 12 and a tail plate 14 arranged in parallel in sequence from the beginning to the end, and through two parallel and perpendicular to the head The guide column 2 of plate 11, positioning plate 12 and tail plate 14 connects head plate 11, positioning plate 12 and tail plate 14 in series, and guide column 2 is positioned at the two ends of head plate 11, positioning plate 12 and tail plate 14 and with Each plate is fixedly connected, a push plate 13 is provided between the positioning plate 12 and the tail plate 14, and the push plate 13 is also connected in series with the guide column 2 and is slidably connected with it, and the head plate 11 is provided with a fixed bearing on the side facing the positioning plate 12 Shelving groove 3, the push plate 13 facing the...

Embodiment 2

[0019] The difference between Embodiment 2 and Embodiment 1 is that the power source 7 is a hydraulic cylinder.

Embodiment 3

[0020] The difference between Embodiment 3 and Embodiment 1 is that an infrared alarm sensor is arranged on the outside of the structure with pushing action in the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com