Inclined capillary tube and construction method thereof

A construction method and capillary technology, applied in heating methods, building components, applications, etc., can solve the problems affecting the energy utilization rate and radiation efficiency of the capillary net, long response time of the capillary, and complicated installation procedures, etc. Exposure risk, simplified structure and installation process, the effect of short installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

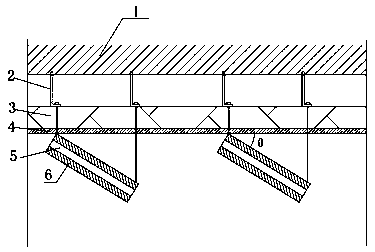

[0026] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0027] An inclined capillary, including a hook 2 pre-buried in the wall 1, the hook 2 is connected to the two ends of the capillary mat support frame 6 through a nylon cable tie, and the capillary mat support frame 6 is installed with a capillary mat 5 , and the lower structural layer 3 and the heat insulating layer 4 are arranged between the capillary mat support frame 6 and the hook 2, and the two ends of the capillary mat support frame are passed through a nylon cable tie and a suspension hook respectively. Hook connection, wherein one end of the capillary mat supporting frame is close to the heat insulation layer, and the other end is installed inclined downward, and the included angle between the inclined angle and the wall is 0-45°.

[0028] The construction method of the above-mentioned inclined capillary, the method comprises the steps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com