Conversion module of electronic ballast-driven LED (light emitting diode)

A technology of electronic ballast and conversion module, which is applied in the electronic field and can solve the problems of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

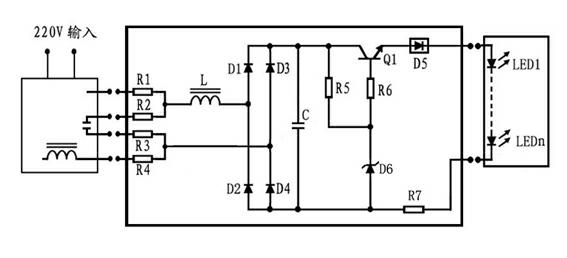

[0012] Below in conjunction with accompanying drawing, the present invention will be further described:

[0013] The electronic ballast drives the LED conversion module, which is connected between the electronic ballast and the LED array. The conversion module includes a high-frequency current limiting circuit for adjusting the high-frequency and high-voltage AC current at the output end of the electronic ballast. The rectification and filtering circuit for rectification and filtering to become a stable DC, the initial voltage stabilization circuit for adjusting the LED drive voltage, the constant current drive circuit for adjusting the current control required by the LED, the high frequency current limiting circuit, the rectification and filtering circuit, The initial voltage stabilizing circuit and the constant current driving circuit are connected together. Among them, the high-frequency current limiting circuit is composed of resistor R1, resistor R2, resistor R3, resistor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com