A ceramic block cutting production line and its cutting processing method

A production line and block technology, applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of high labor intensity, low degree of automation, health hazards of workers, etc., to ensure life and health, improve the level of automation, The effect of improving machining efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing.

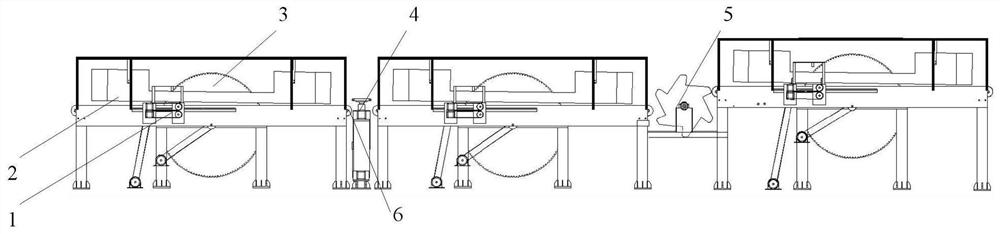

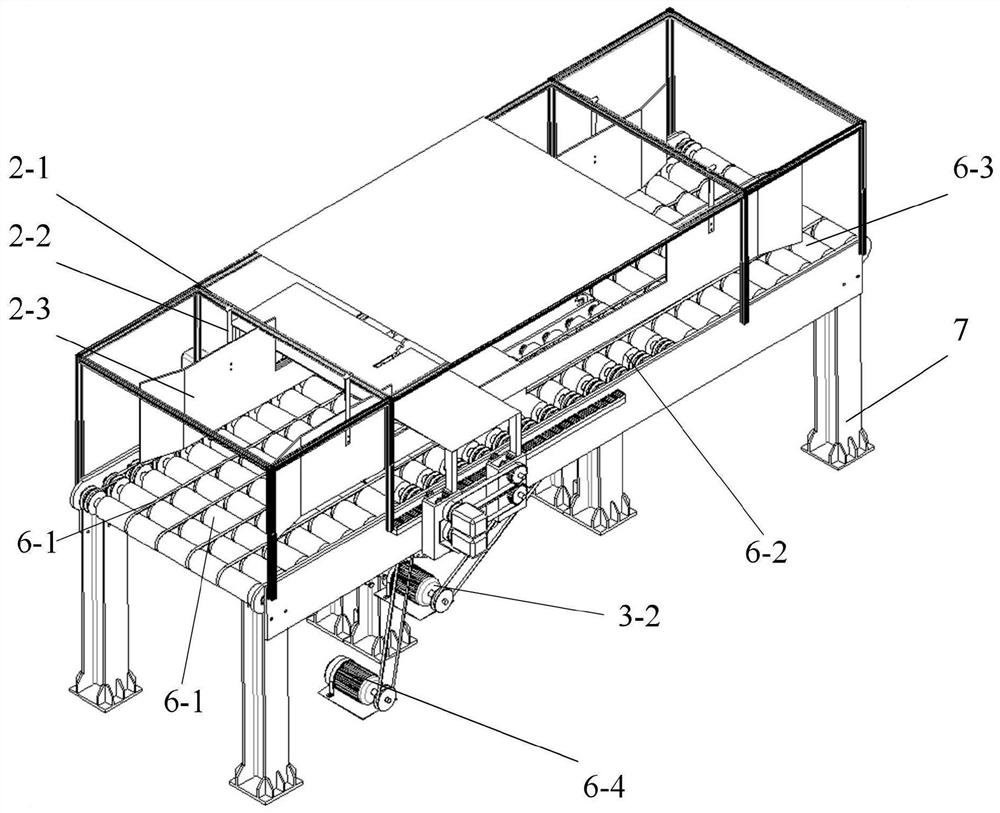

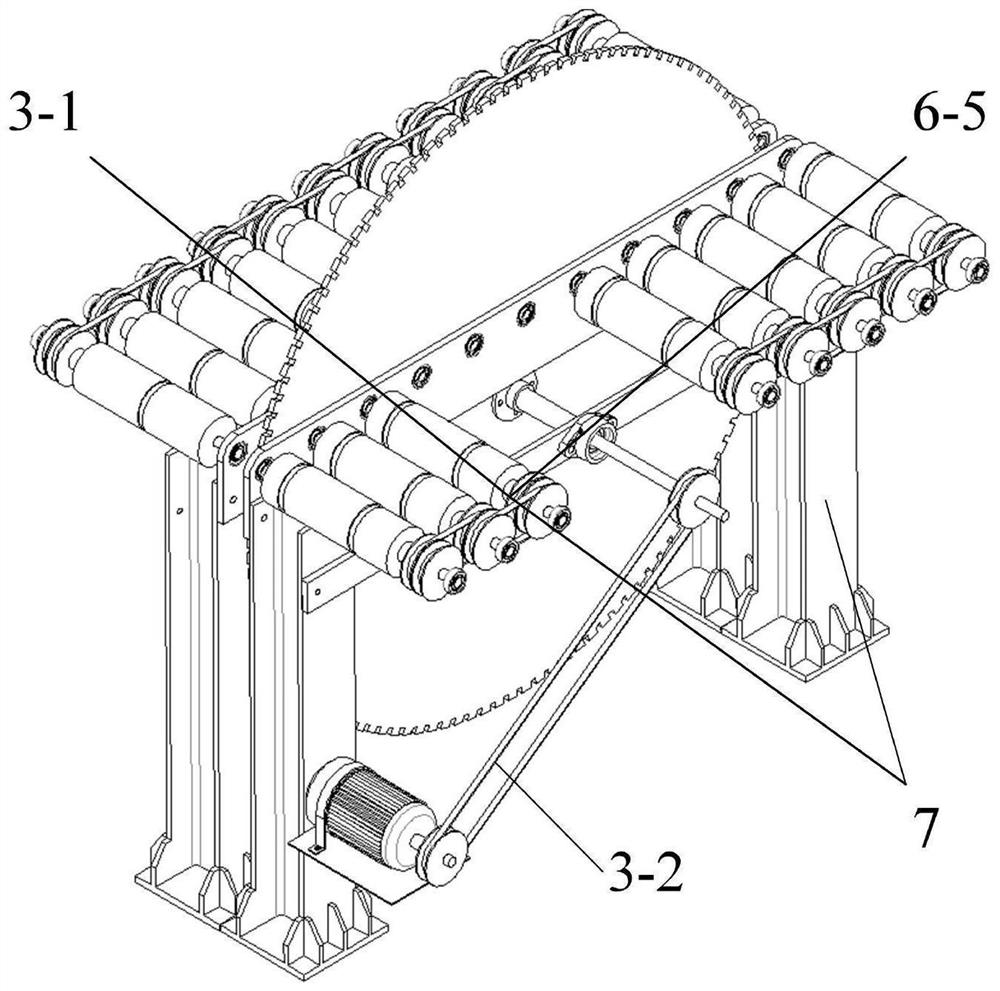

[0037] Such as figure 1 As shown, a ceramic block cutting production line includes a rotating mechanism 4, a turning mechanism 5 and three feeding processing modules. The three feed processing modules are arranged at intervals in sequence. The rotating mechanism 4 is arranged between the first feeding processing module and the second feeding processing module, and is used for rotating the ceramic block to be cut around a vertical axis. The turning mechanism 5 is arranged between the second feeding processing module and the third feeding processing module, and is used for rotating the ceramic block to be cut around a horizontal axis. The three feed processing modules have the same structure, and all include a frame 7, a pressing device 1, a positioning device 2, a sawing system 3 and a power roller conveyor 6. The positioning device 2 , the pressing device 1 , the sawing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com