Preparation method of vitamin A midbody

A technology for intermediates and vitamins, which is applied in the field of preparation of vitamin A intermediates, can solve problems such as poor stability, high production costs, and expensive commercial enzymes, and achieve the effects of less environmental pollution, lower production costs, and strong regional selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

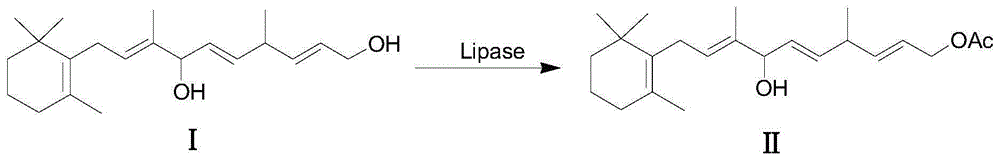

Method used

Image

Examples

Embodiment 1

[0026] Slant culture: inoculate Aspergillus oryzae (Aspergillusoryzae) WZ007 (preservation number CCTCC No. M206105) into the slant medium, and culture at 30° C. for 3 days, as the slant activated seeds. The composition of the final concentration of the slant medium: NaNO 3 0.2%, K 2 HPO 4 0.1%, KCl0.5%, FeSO 4 0.001%, MgSO 4 0.05%, 3% sucrose, 1.5% agar, deionized water as solvent, natural pH, sterilized at 121°C for 20 minutes.

[0027] Fermentation culture: inoculate slant seeds into 1L liquid fermentation medium, culture at 30°C with a shaker speed of 200r / m for 48 hours, filter to obtain 80g wet weight of mycelia, and freeze-dry at 0°C for 24h to obtain 20g of dry mycelium. The final concentration of the liquid fermentation medium consists of: glucose 20g / L, peptone 20g / L, sucrose 10g / L, urea 3g / L, NaCl 5g / L, K 2 HPO 4 2g / L, MgSO 4 1g / L, (NH 4 ) 2 SO 4 5g / L, the solvent is deionized water, the pH is natural, the liquid volume is 80ml in a 500ml Erlenmeyer bottle...

Embodiment 2

[0034] 0.1g of Aspergillus oryzae WZ007 dried thallus and 0.5g of intermediate I prepared by the method of Example 1 were added to 10ml of n-hexane solution containing 10% (volume ratio) ethylene acetate, and placed in a water bath at 30°C and 200rpm. After reacting for 12 hours, filter, and HPLC detects that the reaction conversion rate is 99.5% (regioselectivity 99.0%), and the filtrate is distilled under reduced pressure at 0.1 MPa until no liquid flows out to remove solvent and acylating agent to obtain vitamin E intermediate II with a purity of 97.8%, can be directly used in the next reaction.

Embodiment 3

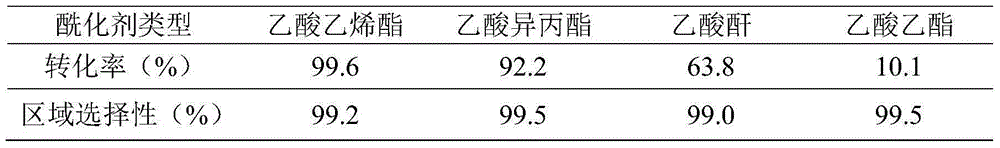

[0036] 0.1g of Aspergillus oryzae WZ007 dried thalline and 0.5g of intermediate I prepared by the method of Example 1 were added to 10ml of n-hexane solutions containing 10% (volume ratio) of different acylating agents, at 30°C and 200rpm, in a water bath After reacting for 12 hours, the reaction solution was filtered, and the conversion rate of the filtrate was detected by HPLC, and the results of enzyme conversion were shown in Table 1.

[0037] Table 1 Enzyme conversion results of different acylating agent types

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com