Wind generating set with bottom driving

A technology of wind power generating set and wind power transmission, which is applied in the direction of wind power motor combination, wind power engine, wind power generation, etc. It can solve the problems of large investment, high price of wind power generator, complicated grid-connected technical route, etc., and achieve low volume and weight requirements , simple structure and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

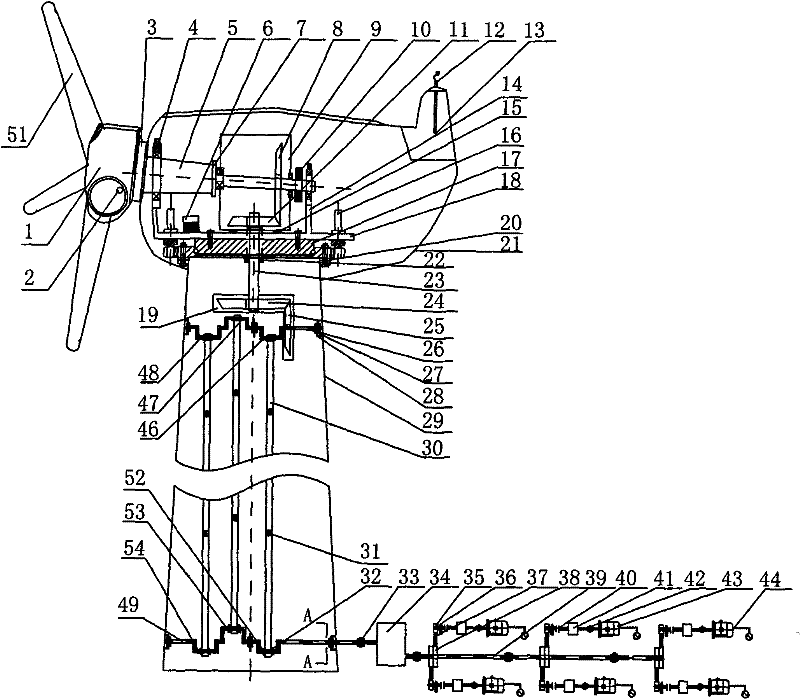

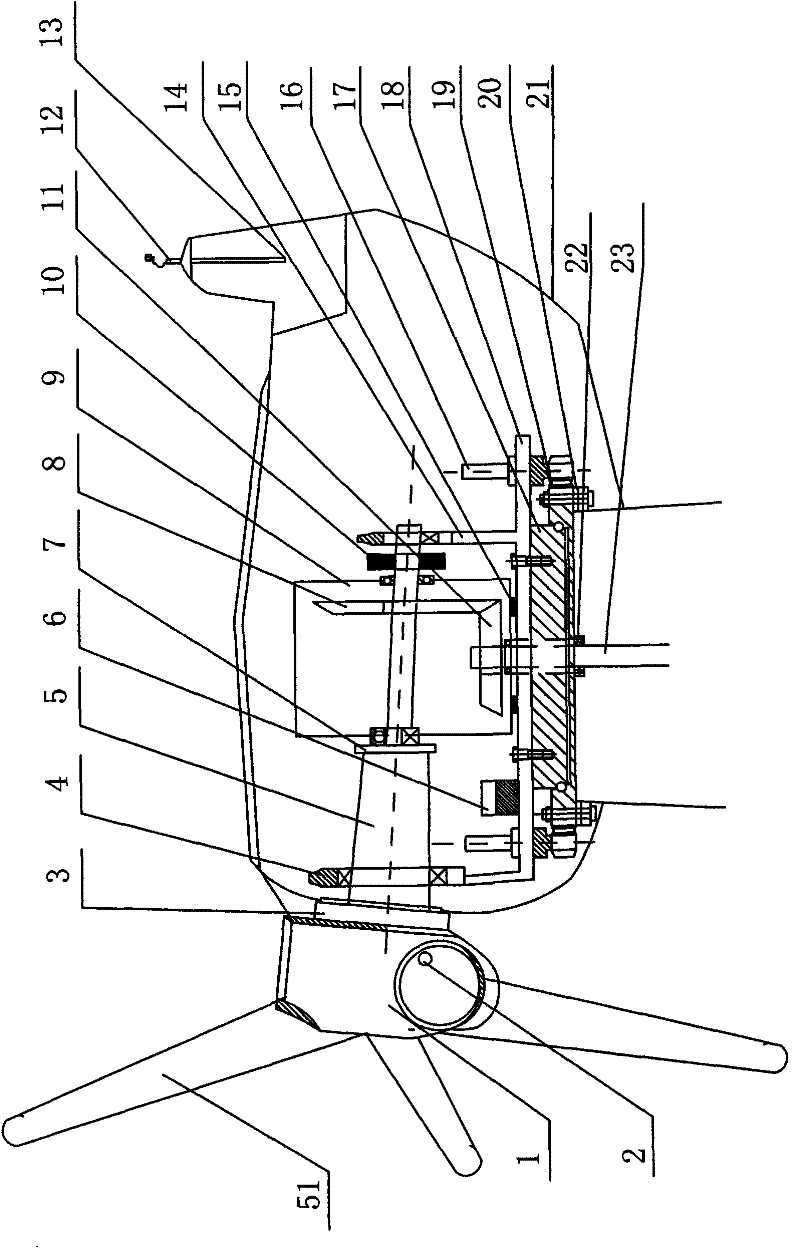

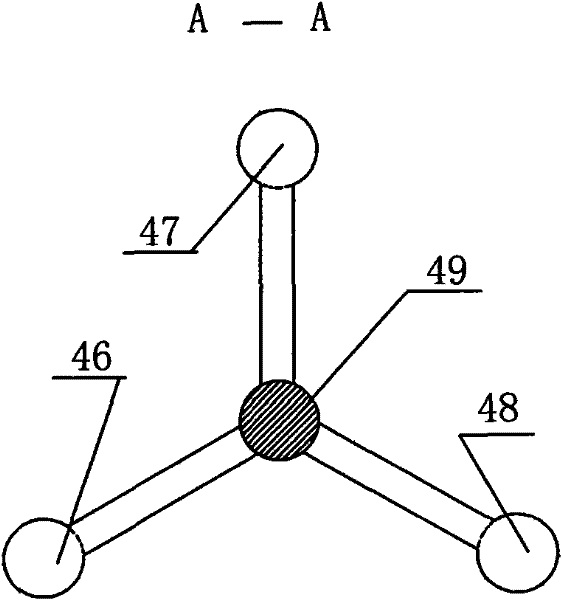

[0039] Bottom drive wind turbine, including wind transmission part, mechanical transmission part, speed increasing part, speed regulating power generation part, control part, nacelle and tower; the entire nacelle 21 is located on the slewing bearing 17 connected to the tower 29, The tower flange 20 is connected to the tower 29. The above-mentioned wind transmission part includes blades 51 and a hub 1; the blades 51 are connected to the hub 1 by a flange, and the hub 1 is installed at the front end of the nacelle 21; the blades 51 rotate under the action of wind to generate power, and the hub 1 and the rear mechanical transmission Partially connected to transmit the rotational power generated by the blade 51;

[0040] A pitch device 2 is installed at the root of the blade 51. The pitch device 2 is movably connected to the blade 51. Under the action of the pitch device 2, the blade 51 can rotate around the hub 1 in a circle. The start wind speed and the rated wind speed The blades...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com