Heat insulation greenhouse for pool and building method of heat insulation greenhouse for pool

A technology of thermal insulation greenhouse and construction method, applied in fish farming, application, animal husbandry, etc., can solve the problems of high maintenance cost, indurability, small span, etc., to save heating energy, long service life, and solve the problem of small span Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

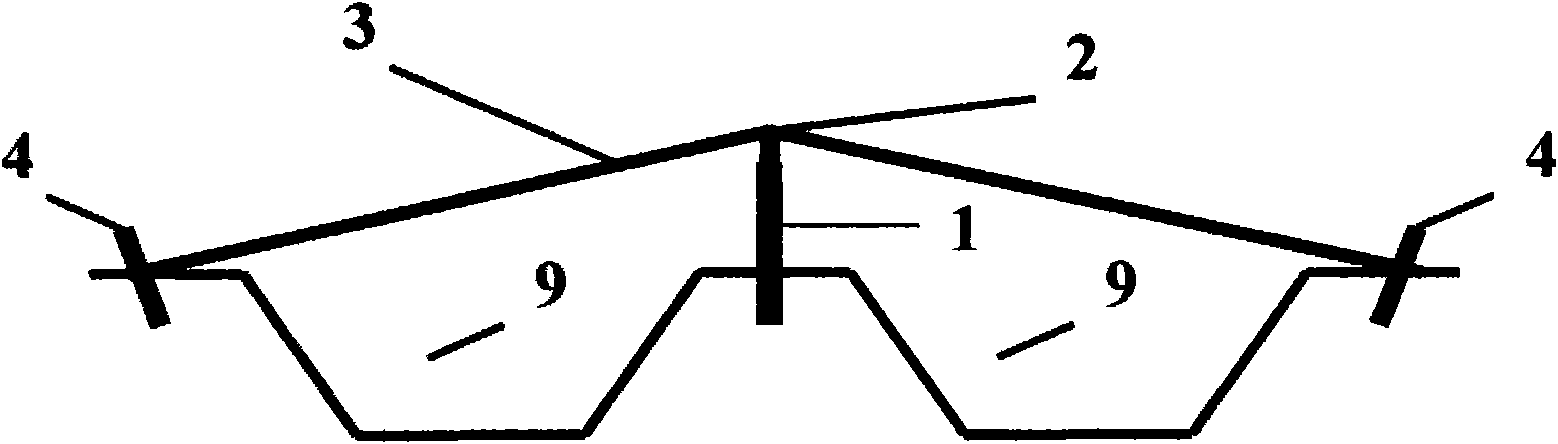

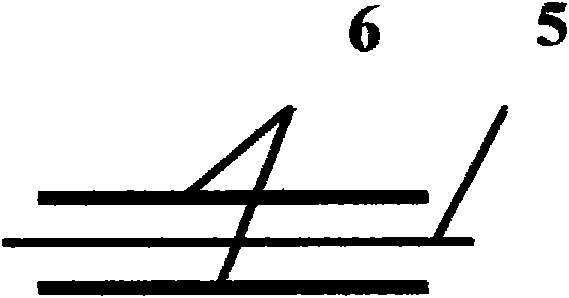

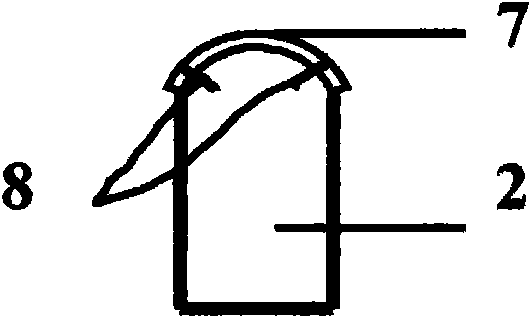

[0010] The present invention (refer to the drawings) adopts a column 1, a beam 2, a foundation pile 4, a plastic film 5, and a rope 6 composed of a foundation 11 and a pile body 10. In the invention, a plurality of reinforced concrete columns are constructed on the ridge between two adjacent ponds 9 and on the banks at both ends of the pond respectively. The columns are cylindrical. The position of the reinforced concrete column in the building is excavated according to the cross-sectional specifications of the reinforced concrete column. , And poured with soil molds to reduce damage to the soil structure around the reinforced concrete column. The compaction coefficient of the soil layer at the construction site is above 0.9; the top of the reinforced concrete column supports a reinforced concrete beam, and the cross section of the reinforced concrete beam is rounded. The arc-shaped fixed member 8 is used to fix the arc-shaped plate 7; the bearing capacity of the reinforced conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com