Method for removing and inhibiting fishy smell of aquatic animal enzymatic hydrolysate

A technology for aquatic animals and enzymatic hydrolyzate, which is applied in the field of removing and inhibiting the fishy smell of aquatic animal enzymatically hydrolyzed liquid. It can solve the problem of deodorization mechanism and reliability that need to be further studied. It is easy to lose the nutrients and active ingredients of the treatment ingredients, and cannot prevent the oxidation of fatty acids. Deterioration and other problems, to achieve the effect of good deodorization effect, low equipment requirements, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Remove the shells of Paphia rugosa, take the meat and wash it, add 4 times the volume of deionized water to homogenate for 5 minutes, and then add neutral protease. The conditions are as follows: pH6, enzymolysis time is 4 hours, enzymolysis temperature is 60°C, after the reaction is completed, the enzyme activity is inactivated in a boiling water bath for 5 minutes, centrifuged at a high speed at a speed of 3000r / min for 15 minutes, and the supernatant is obtained to obtain the clam. Enzyme solution.

[0021] Adding 0.5% volume fraction of ethanol volume fraction of 95% food-grade alcohol to the clam enzymolysis solution, and then treating it in a constant temperature water bath at 60°C for 1 hour to obtain the food-grade alcohol treatment solution, Then be placed in 20 ℃ of constant temperature water baths and cool, then add its quality 0.05% green tea extract and its quality 0.9% water-soluble ginger oil in the above-mentioned edible grade alcohol treatment liquid, a...

Embodiment 2

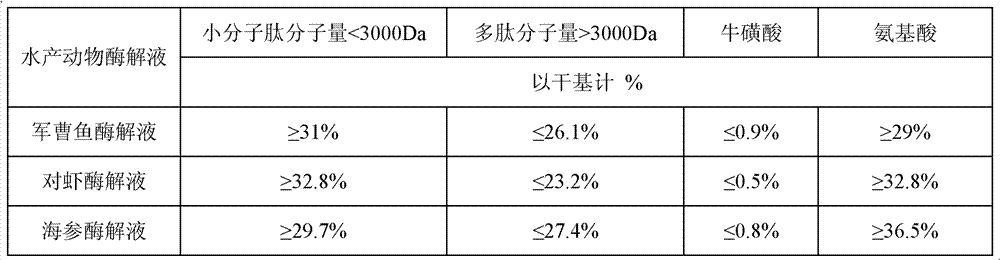

[0045] Remove the scales and viscera of cobia, take the meat and wash it, add 3 times the volume of deionized water to homogenate for 5 minutes, then add papain, the ratio of enzyme to substrate is 1000U per gram of cobia, and the enzymatic hydrolysis condition is: pH 7 , enzymatic hydrolysis time 6h, enzymolysis temperature 50°C, after the reaction is over, boil the water bath for 5min to inactivate the enzyme activity, centrifuge at a high speed for 15min at a speed of 3000r / min, take the supernatant, and obtain the cobia enzymatic hydrolyzate, the nutritional composition of which is shown in the table 2.

[0046] Table 2: Nutrient composition of various raw materials after hydrolysis with different proteases

[0047]

[0048] Add 0.1% of the cobia enzymatic hydrolyzate to the cobia enzymatic hydrolyzate, 0.1% of the ethanol volume fraction is 95% food-grade alcohol, and treat it in a constant temperature water bath at 60°C for 0.5h to obtain a food-grade alcohol treatmen...

Embodiment 3

[0052] Remove the shells of the prawns, take the meat and wash it, add 4 times the volume of deionized water to homogenate for 5 minutes, add flavor protease, the ratio of enzyme to substrate is 2000U per gram of prawn meat, and the enzymatic hydrolysis conditions are: pH 6, enzymatic hydrolysis After 2 hours, add bromelain, the amount of enzyme added is 1000U / g, the enzymolysis temperature is 50°C, and the enzymolysis is 5 hours. After the reaction is completed, the enzyme activity is inactivated in a boiling water bath for 5 minutes, and the high-speed centrifugation is carried out at a speed of 3000r / min for 15 minutes, and the supernatant is taken. The prawn enzymatic hydrolyzate was obtained, and its nutrient composition is shown in Table 2.

[0053] Add food-grade alcohol with a volume fraction of 0.4% of ethanol in the enzymatic solution of prawns to the enzymatic solution of prawns, and treat it in a constant temperature water bath at 40°C for 1.5 hours to obtain an edi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com