Hot-rolled coated steel bar for on-line spraying anti-corrosive coating material and preparation method thereof

A technology for anti-corrosion materials and spraying equipment, applied in the direction of coating, metal material coating process, melt spraying, etc., can solve the problems of high cost and low efficiency, achieve convenient operation, stable process, delay oxidation or corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

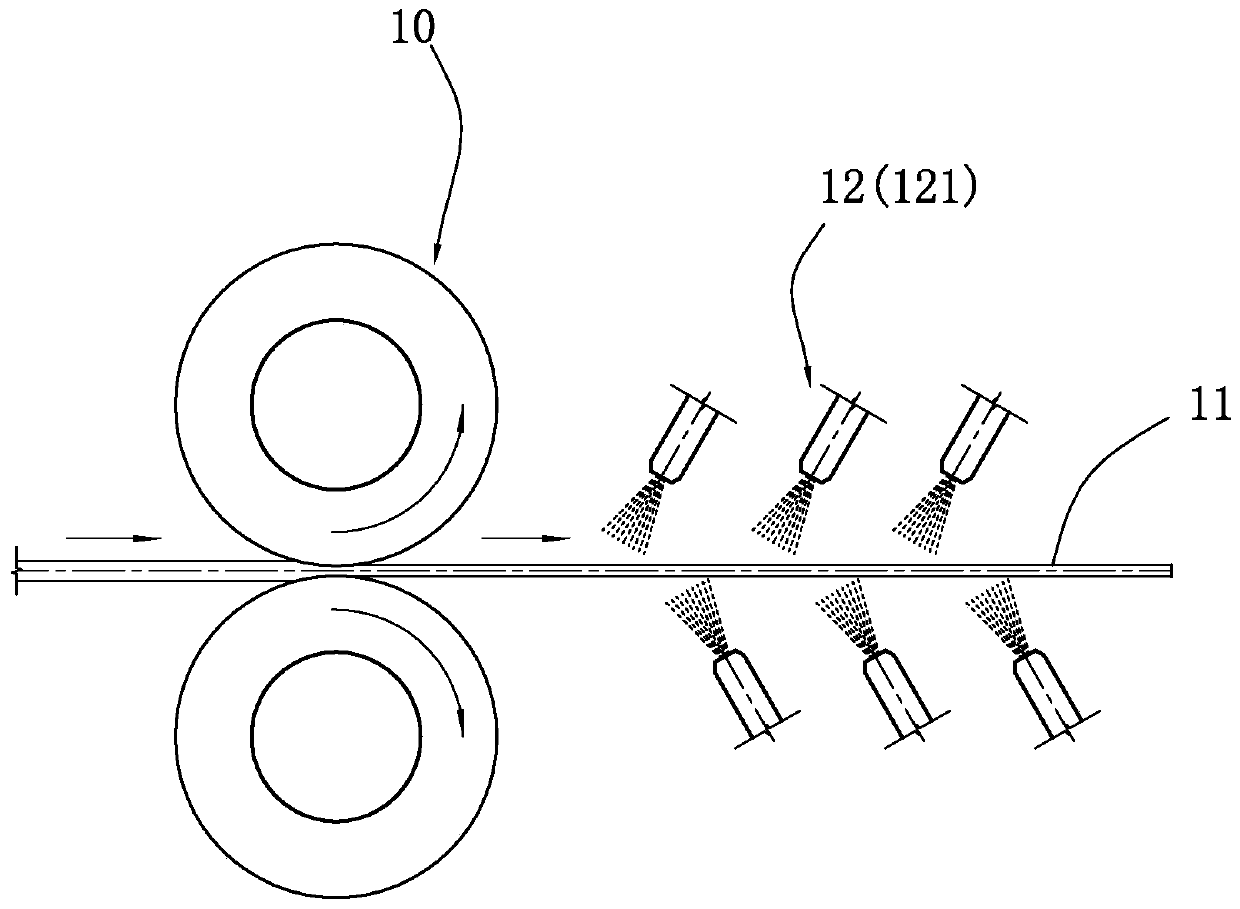

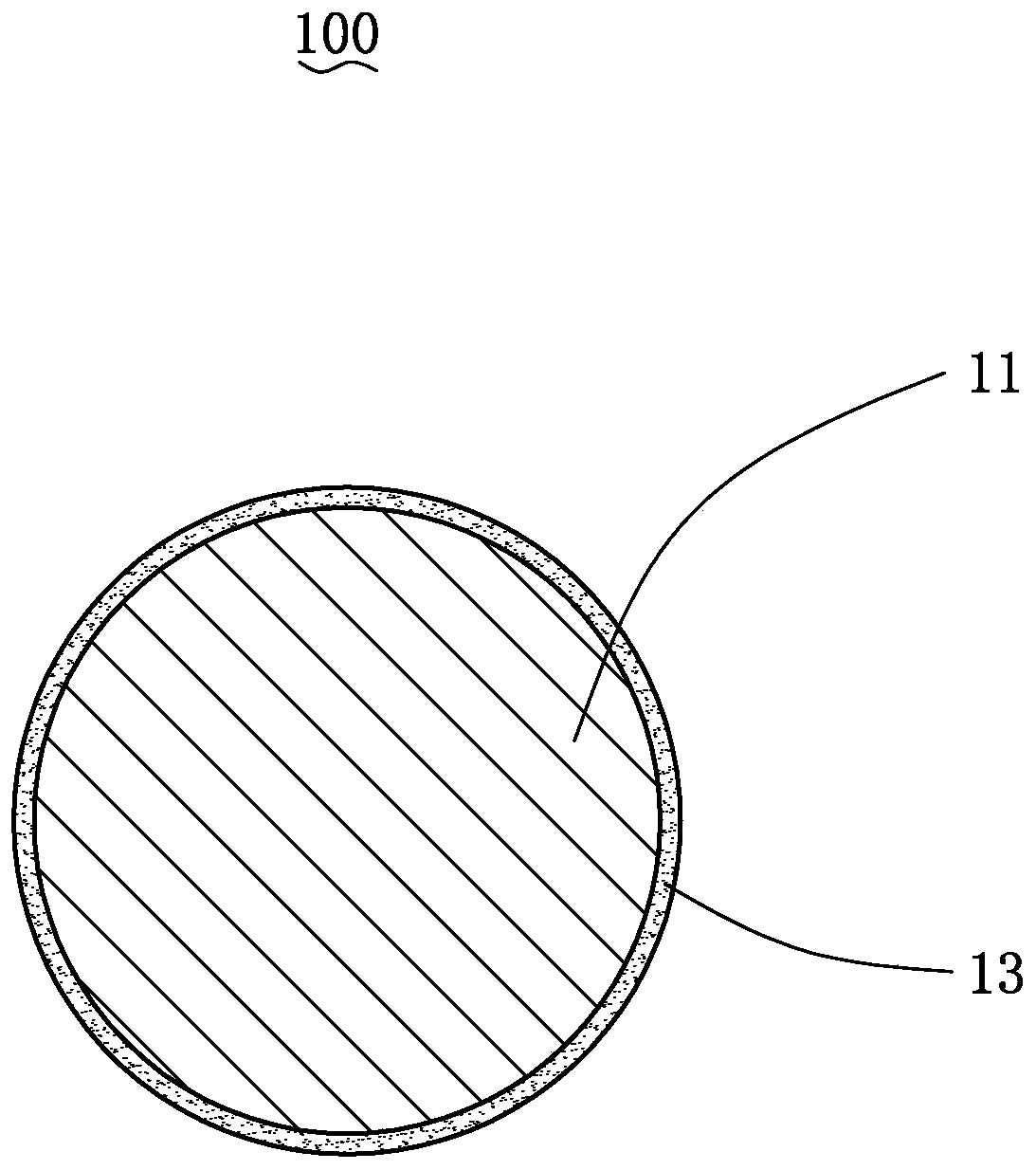

[0037] Please refer to image 3 , is a schematic diagram of Example 1 of the method for preparing hot-rolled clad steel bars with on-line spray coating of anti-corrosion coating materials provided by the present invention. In this embodiment, an aluminum cladding material with a thickness of 0.07 mm is sprayed on the surface of a HPB300 round steel with a diameter of 12 mm in three sections as an example to illustrate the method for preparing a hot-rolled clad steel bar with an on-line spray-coated anti-corrosion cladding material of the present invention. The round steel is hot-rolled by the hot rolling mill 10, and the line speed at the output of the hot rolling mill is 10m / s, and the weight of the aluminum coating on the surface of the single-line steel bar per hour is about:

[0038] Round steel diameter*3.14*coating thickness*aluminum density*exit line speed*3600 seconds=0.12(dm)*3.14*0.07(mm) / 100*2.7(kg / dm)*100(dm / s)* 3600s = 256kg.

[0039]Each hot-rolled steel bar 11...

Embodiment 2

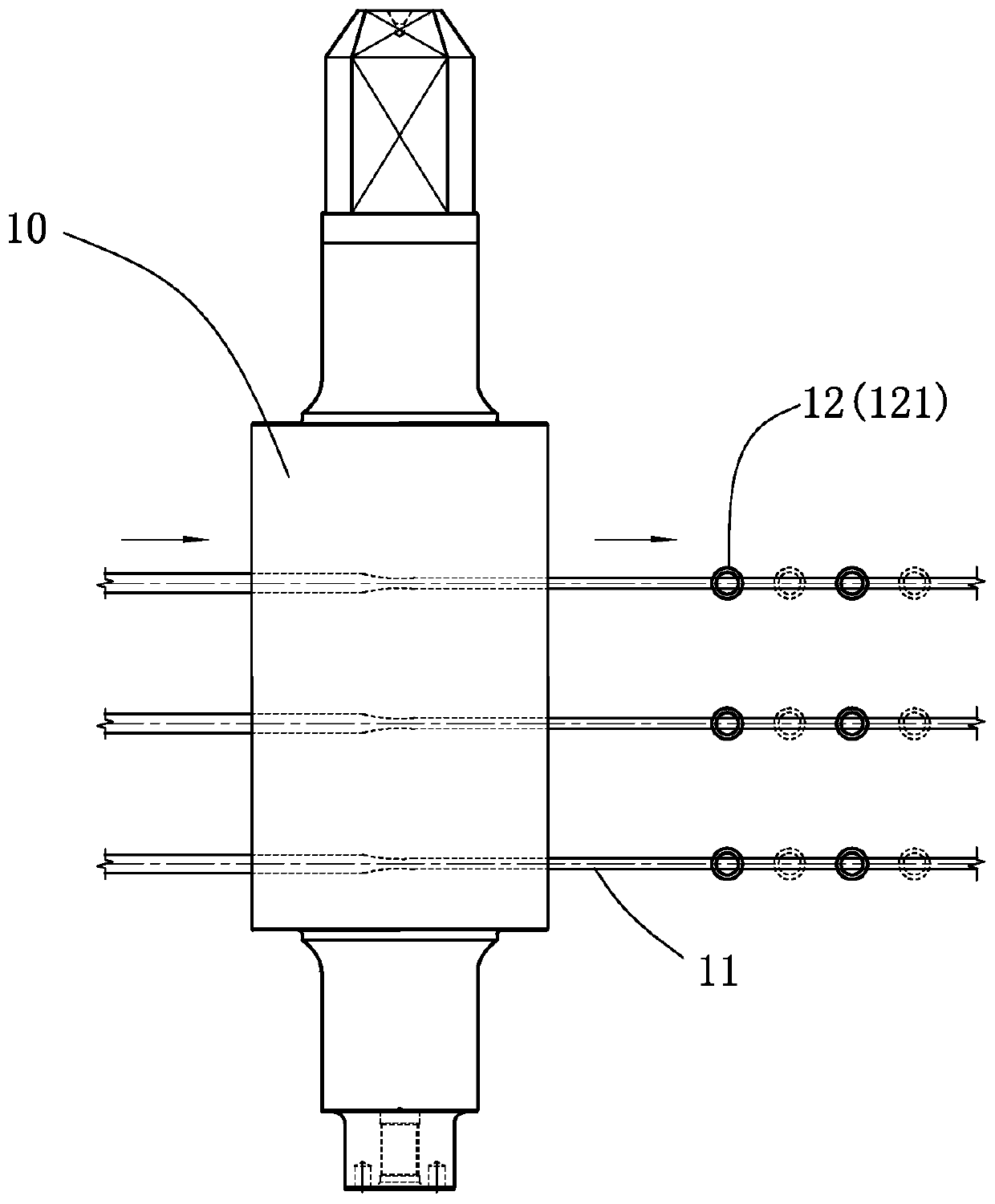

[0042] Please refer to Figure 4 , is a schematic diagram of Example 2 of the method for preparing hot-rolled clad steel bars with on-line spray-coated anti-corrosion coating materials provided by the present invention. In this embodiment, the method of the present invention is illustrated by spraying a 0.10 mm stainless steel cladding layer on the surface of HRB400 rebar with a diameter of 18 mm in two sections as an example. The line speed of the rebar at the outlet of the hot rolling mill is 6 m / s, and the weight of the stainless steel cladding on the surface of the single-line steel bar per hour is about:

[0043] Rebar diameter*3.14*coating thickness*stainless steel density*exit line speed*3600 seconds=0.18(dm)*3.14*0.10(mm) / 100*8.9(kg / dm)*60(dm / s)* 3600s = 1086kg.

[0044] Each hot-rolled steel bar 11 is provided with six groups of spraying equipment 12 correspondingly. The spraying equipment 12 is a high-speed electric arc spraying machine. There are three sets of ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com