Water cooling motor casing and water passage sealing structure of water cooling motor casing

A water-cooled motor and sealing structure technology, which is applied in the direction of casing/cover/support, electrical components, electromechanical devices, etc., can solve the problems of complicated manufacturing process, troublesome assembly, poor waterproof sealing effect, etc., and achieve simple processing and production The effect of high efficiency and low cost

Inactive Publication Date: 2012-08-29

TIANJIN SANTROLL ELECTRIC AUTOMOBILE TECH CO LTD

View PDF5 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

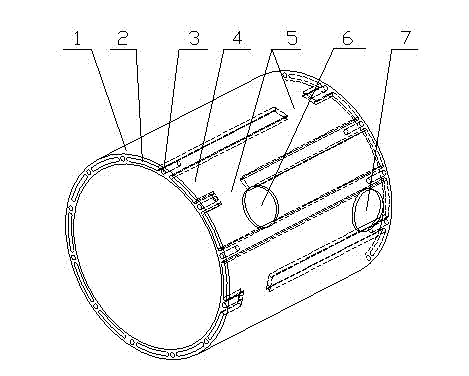

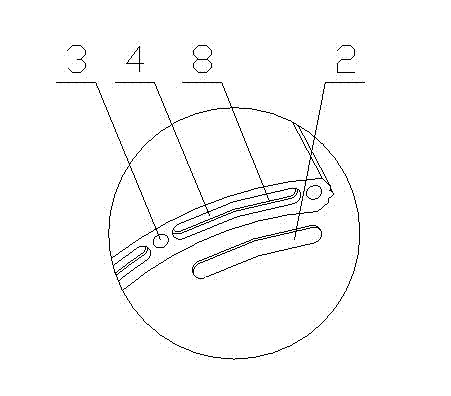

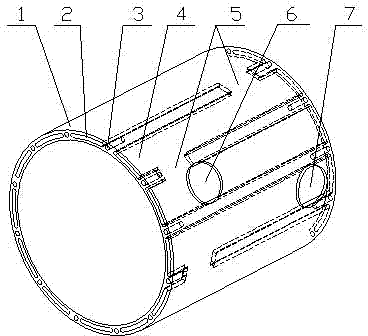

The invention provides a water cooling motor casing and a water passage sealing structure of the water cooling motor casing. A plurality of axial direct through holes are arranged on the side wall of the casing for forming water passages, the two ends of each direct through hole are sealed, communication holes are arranged between the direct through holes so that the water passages are connected, step grooves are arranged on the inner walls of the two side end parts of the water passages and are used for fixing and placing thin sheet aluminum strips, sealing glue is filled after the aluminum strips are placed, the aluminum strips are fixed, and in addition, the water passages are sealed. The process is simple, the production efficiency of a water cooling motor can be effectively improved, in addition, the sealing performance is high, and the safety is high.

Description

technical field [0001] The invention relates to the technical field of motors, in particular to a water-cooled motor casing. Background technique [0002] For motors with large power, severe heat generation and poor heat dissipation environment, certain protection measures are generally required. In particular, the motor of electric / hybrid vehicles not only generates a lot of heat during its own work, but also the temperature of the equipment connected to the motor is very high, which transfers a large amount of heat to the motor, which further increases the temperature of the motor and seriously affects to the performance and efficiency of the motor. At present, cooling water jackets are generally used to cool down the motor, that is, to open a water channel on the outer wall of the motor and seal it through a sleeve, or to open a water channel on the motor casing, so that the water flows through the spiral or annular water channel to take away the motor. on the heat. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H02K5/20H02K5/10

Inventor 周爱颖

Owner TIANJIN SANTROLL ELECTRIC AUTOMOBILE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com