Load detection device mounting structure

A detection device and load technology, used in transportation and packaging, special positions of vehicles, stools, etc., can solve problems such as disconnection, bending and deformation of signal lines, and achieve the effect of suppressing disconnection or damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

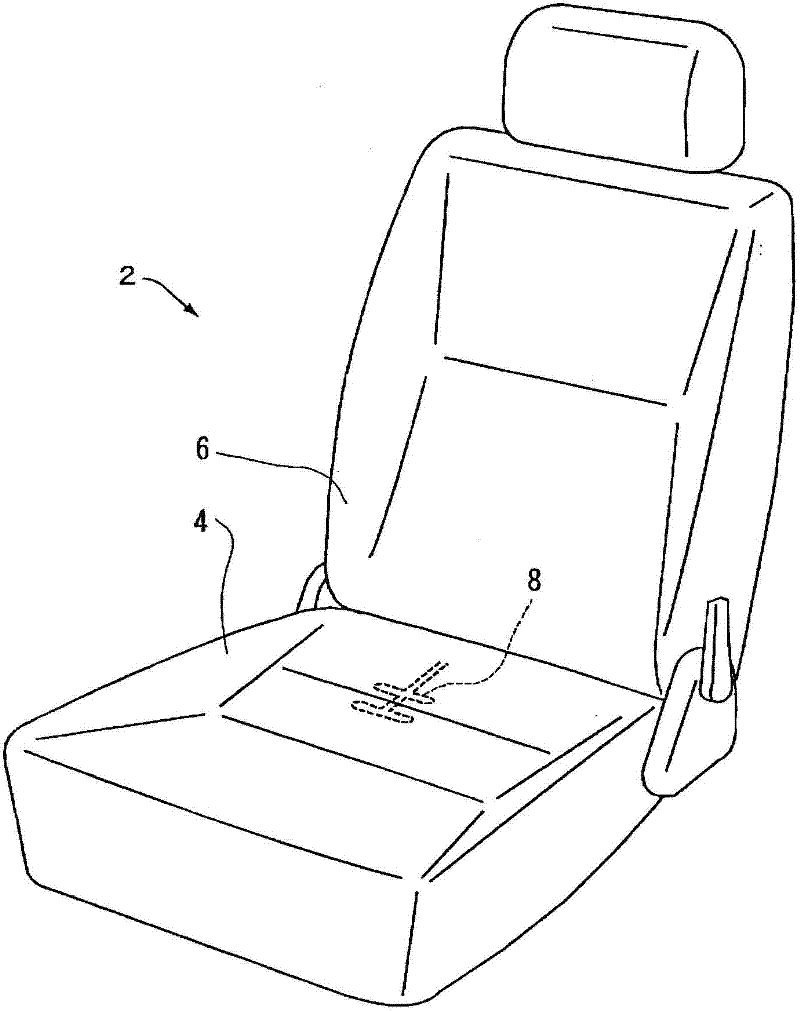

[0034] Hereinafter, a first embodiment in which the mounting structure of the seating detection device for a vehicle seat according to the present invention is applied to a vehicle seat will be described with reference to the drawings. However, the directions of "front and rear, left and right, and up and down" used in this specification are all described based on the vehicle.

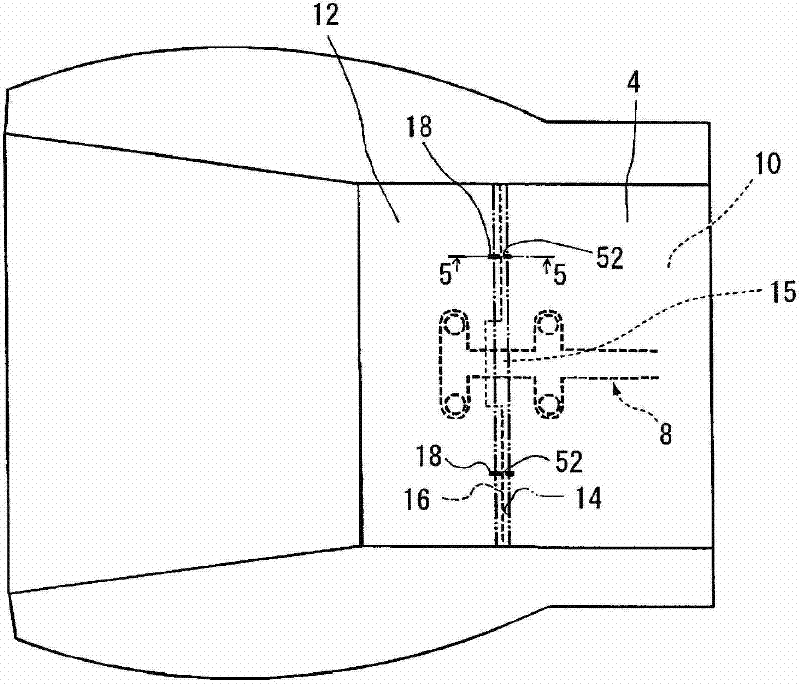

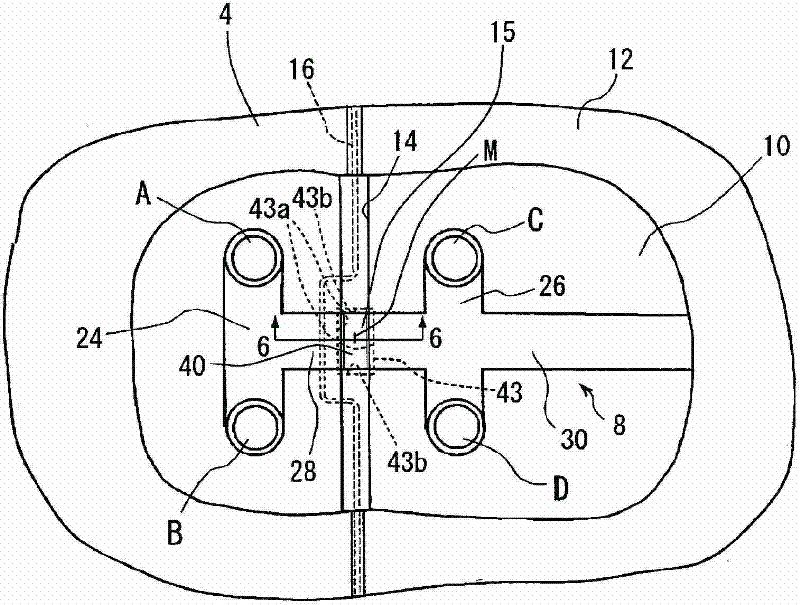

[0035] Such as figure 1 As shown, the vehicle seat 2 includes a seat cushion portion 4 , a film-shaped load detection device 8 , and a seat back portion 6 . Such as figure 2 , image 3 As shown, the seat cushion portion 4 is provided with: a cushion member 10, which is made of polyurethane or the like; The way the surface is mounted. Such as image 3 As shown, a part of the upper surface of the cushion member 10 of the seat cushion portion 4 is recessed to form a groove along the left-right direction ( image 3 The groove 14 extending in the up and down direction).

[0036] The load detection d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com