Control Method of Multiple Parallel Fume Hoods

A control method and technology for fume hoods, which are applied in cleaning methods and utensils, chemical instruments and methods, and smoke and dust removal, etc., can solve the problem of uneven wind speed, high energy consumption, and inability to achieve simultaneous exhaust and supplementary air for multiple fume hoods and other problems to achieve the effect of keeping the temperature unchanged and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

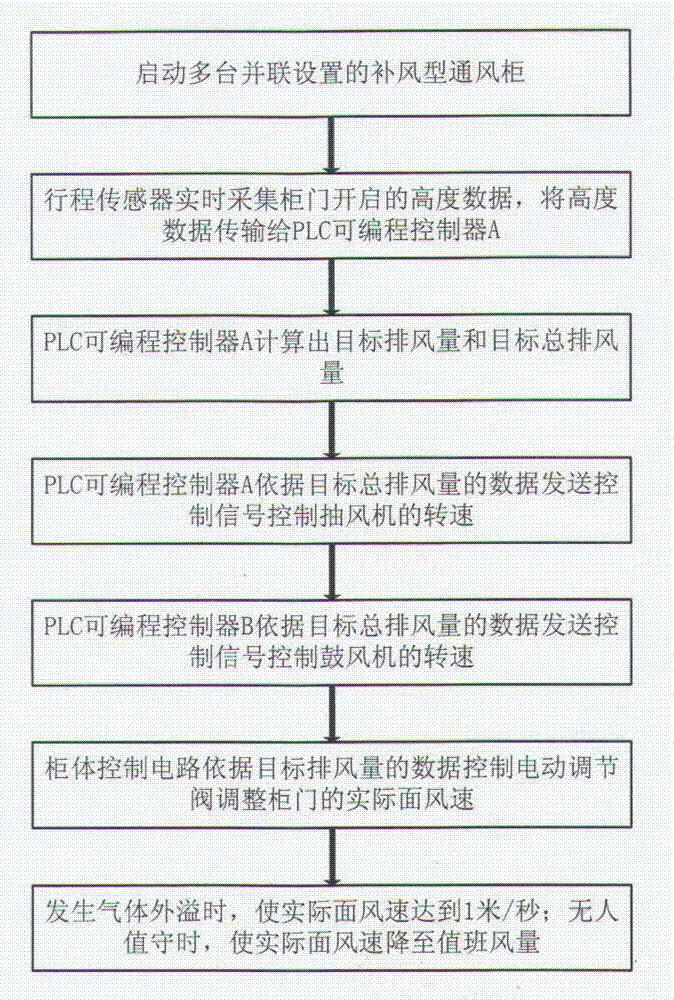

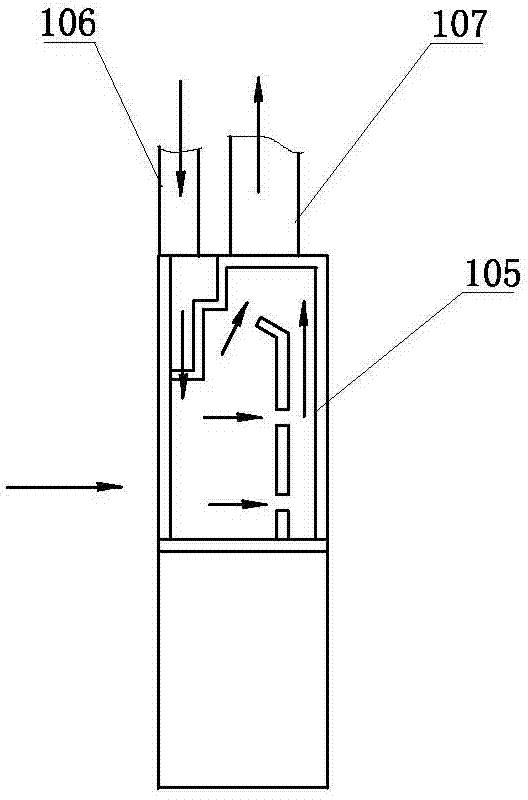

[0025] see figure 1 , the control method of multiple parallel fume hoods of the present invention uses multiple air supply type fume hoods, exhaust main pipe devices, and air supply main pipe devices arranged in parallel;

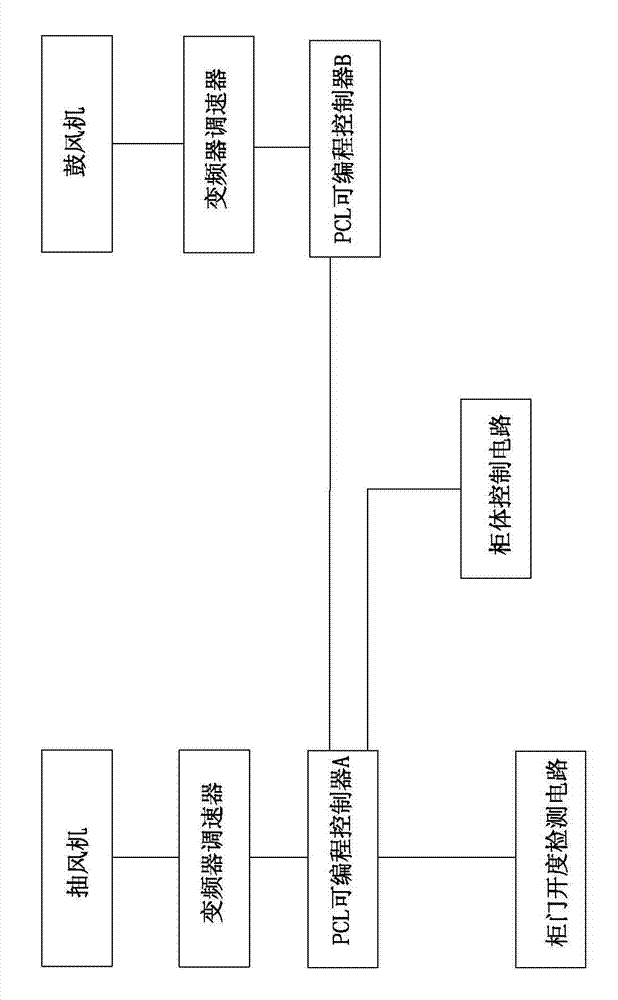

[0026] A. Start the multiple air supply type fume hoods set in parallel, the electric control valve in the exhaust air branch pipeline is opened, and the operation panel in the cabinet control circuit displays the actual surface wind speed value of the air supply type fume hood cabinet door in real time ;

[0027] B, start the cabinet door opening detection circuit, the stroke sensor in the cabinet door opening detection circuit collects the height data of the sliding window type cabinet door opening of the described air supplement type fume hood in real time, and the height data is real-time is transmitted to the PLC programmable controller A in the exhaust main pipe device;

[0028] C, described PLC programmable controller A calculates the area value of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com