Device for fire resistance tests of pressure elements

A fire resistance test and pressure element technology, applied in the field of testing machines, can solve the problem of lack of test equipment, and achieve the effects of high equipment safety performance, accurate test data and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

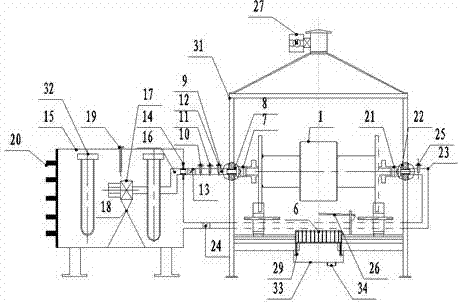

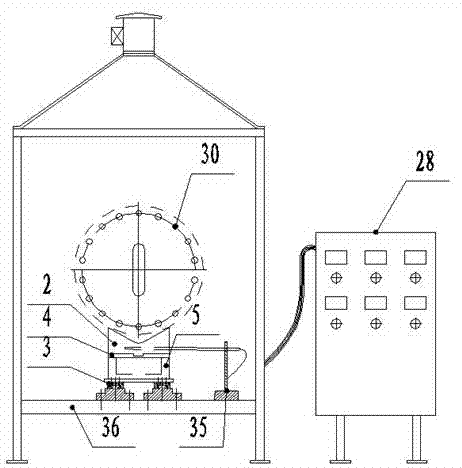

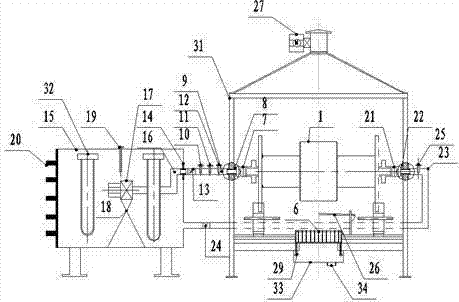

[0020] Such as figure 1 , figure 2 As shown, 31 in the figure is a fire test box, 28 is a power control cabinet, and 15 is a water tank. The bottom of the fire test box 31 is provided with a V-shaped support block 2 for placing the test element 1. In the V-shaped support block 2 and the bottom plate 36 of the fire-resistant test box are provided with a fine-tuning mechanism 4, a height adjuster 5, and a linear guide rail 3 in sequence; a burner 6 with a height adjustment bolt 29 is also arranged on the bottom plate 36 of the fire-resistant test box; A connecting pipe fitting 8, 22 is respectively fixed on the corresponding side wall of the box, and the connecting pipe fitting 8, 22 is connected to the fire resistance test box with the hose 7, 21 and the connecting flange 30 of the test element 1, wherein One connecting pipe 7 is connected outwardly with the outlet of the flow pump 17 in the water tank 15 through the water inlet pipe 9 , while the other connecting pipe 2 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com