High-voltage conductor end ground clamp

A technology for grounding clips and high-voltage wires, which is used in conductive connections, connections, and electrical component connections. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

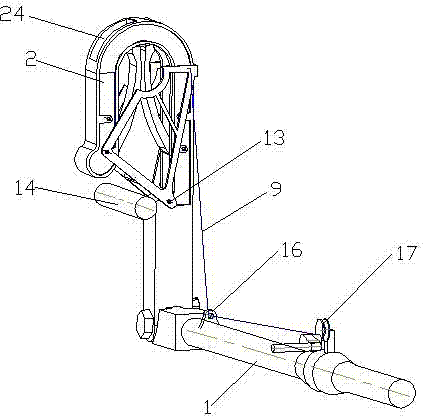

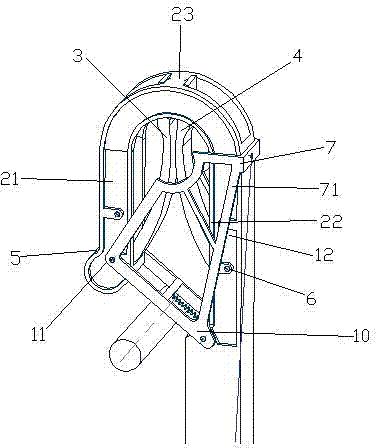

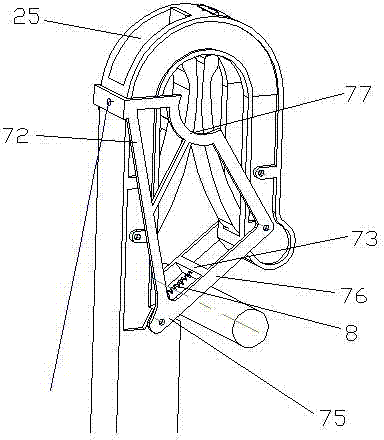

[0016] Such as figure 1 As shown, the high-voltage wire end grounding clip of the present invention includes an operating lever 1, a hook 2 with a wire grounding end, a left tongue 3, a right tongue 4, a left tension spring 5, a right tension spring 6, and a lock block 7, torsion spring 8, insulating stay cord 9, connecting pin 10, hook is made of left clamping part 21 and right clamping part 22 and the bending part 23 that connects left clamping part 21 and right clamping part 22, and bending part The top surface of 23 is provided with two symmetrically arranged left grooves 24 and right grooves 25, the lower end of the right clamping part 22 is connected with the operating rod 1, the left clamping part 21 is parallel to the right clamping part 22, The left tongue 3 and the right tongue 4 are bifurcated and arranged in the hook 2, where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com