Automatic blanking manger for feeding domestic fowls

An automatic and blanking technology, applied in the poultry industry, application, animal husbandry and other directions, can solve the problems of not taking into account the feeding habits of chickens, the feed cannot flow out from the outlet, and the outlet is more blocked. Achieving the effect of reducing feed capacity, avoiding waste, and reducing differences in nutritional content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

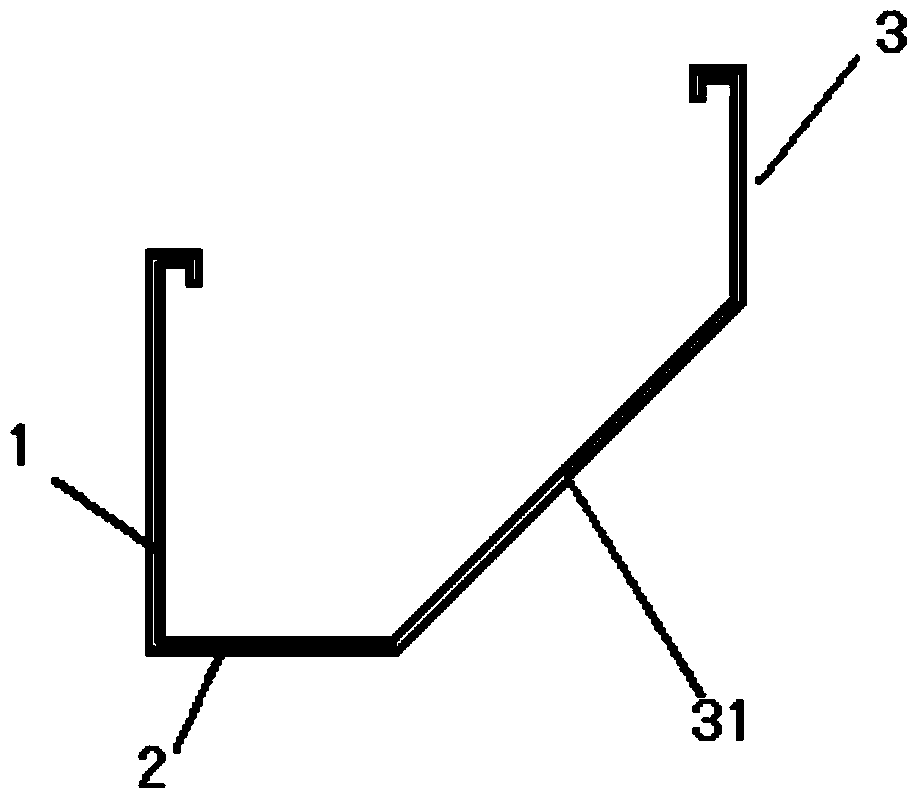

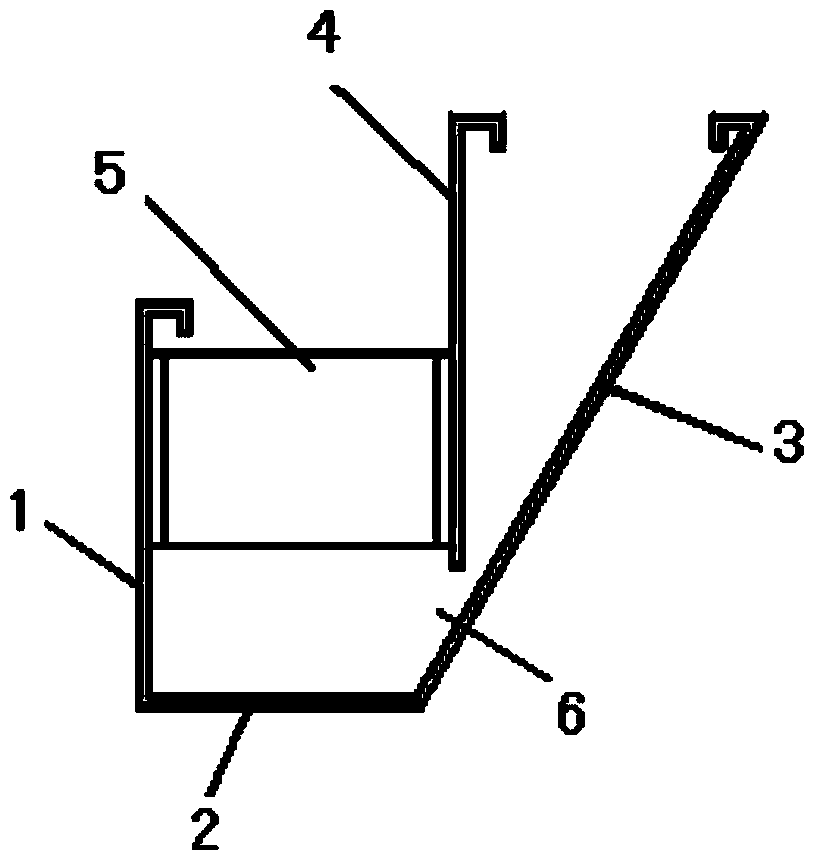

[0028] like figure 1 , figure 2As shown, the present invention comprises an inner baffle 1 arranged on one side when the chickens eat food, a base plate 2 connected to the bottom of the inner baffle 1 and an outer baffle connected to the outside of the base plate 2 opposite to the inner baffle 1 3, and then form a long groove. The connection between the lower part of the outer baffle 3 and the bottom plate 2 has an inward inclined section 31. Above the inclined section 31, a flat partition 4 is vertically arranged between the inner baffle 1 and the outer baffle 3. The partition The top of the 4 is flush with the top of the outer baffle 3, and there is a gap between the bottom of the baffle 4 and the inclined section 31, and the baffle 4 is fixedly connected with the inner baffle 1 through a plurality of support plates 5 arranged at intervals. . Like this, the space between the dividing plate 4 and the outer baffle 3 forms the material storage area, the space between the di...

Embodiment 2

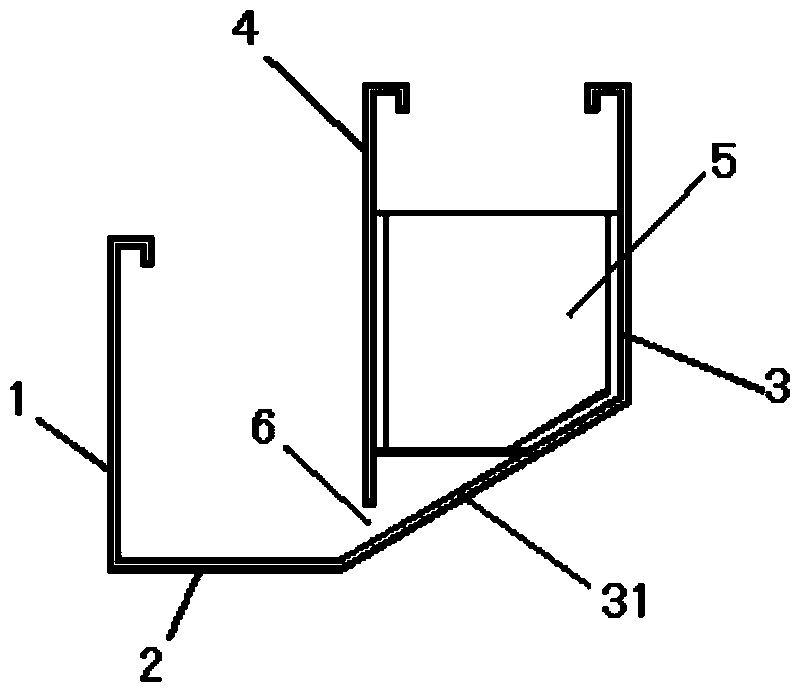

[0033] like image 3 As shown, the structure of the trough of this embodiment is basically the same as that of Embodiment 1, the difference is that the partition 4 is connected to the outer baffle 3 by a number of support plates 5 arranged at intervals, and the gap between the partition and the outer baffle 3 The supporting plate 5 in between separates the storage area into a plurality of independent storage areas.

[0034] In this embodiment, the gap between the bottom end of the dividing plate 4 and the inclined section 31 of the outer baffle 3 can be 4mm, and the angle between the inclined section 31 of the outer baffle 3 and the horizontal direction is 30°, and the included angle can also be It varies according to the amount of feed supplied.

[0035] like Figure 4 , Figure 5 As shown, in this embodiment, the support plate 5 includes a plane plate body 51, one side of the plane plate body 51 is a vertical fold 52, and the other side is a bent fold 53 corresponding to ...

Embodiment 3

[0038] like Figure 6 As shown, the structure of this embodiment is basically the same as that of Embodiment 1 or 2, the difference is that: the bottom of the partition 4 is also provided with an inward inclined section 41, and the bottom end of the inclined section 41 of the partition 4 is located outside The outlet 6 is formed above the inclined section 31 of the baffle plate 3 and has a certain gap with the inclined section 31 of the outer baffle plate 3 .

[0039] In this embodiment, the gap between the bottom end of the inclined section 41 of the partition 4 and the inclined section 31 of the outer baffle 3 is 4 mm, or greater than 4 mm, and the distance between the bottom end of the inclined section 41 of the partition 4 and the inner baffle 1 is 4 mm. The horizontal distance is 25mm, the angle between the inclined section 41 of the partition plate 4 and the horizontal direction is 60°, the angle between the inclined section 31 of the outer baffle 3 and the horizontal di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com