Method for preparing acidification stripped vermiculite supported TiO2 photocatalyst

A photocatalyst and vermiculite technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of difficult separation and recycling, and achieve easy separation and recycling, low preparation cost, The effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

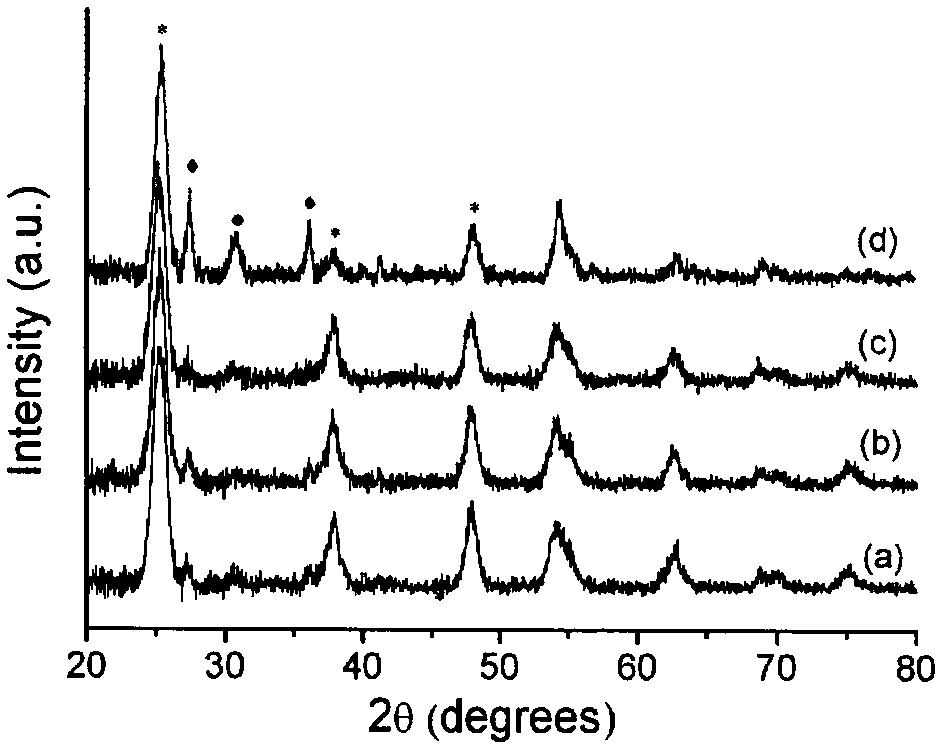

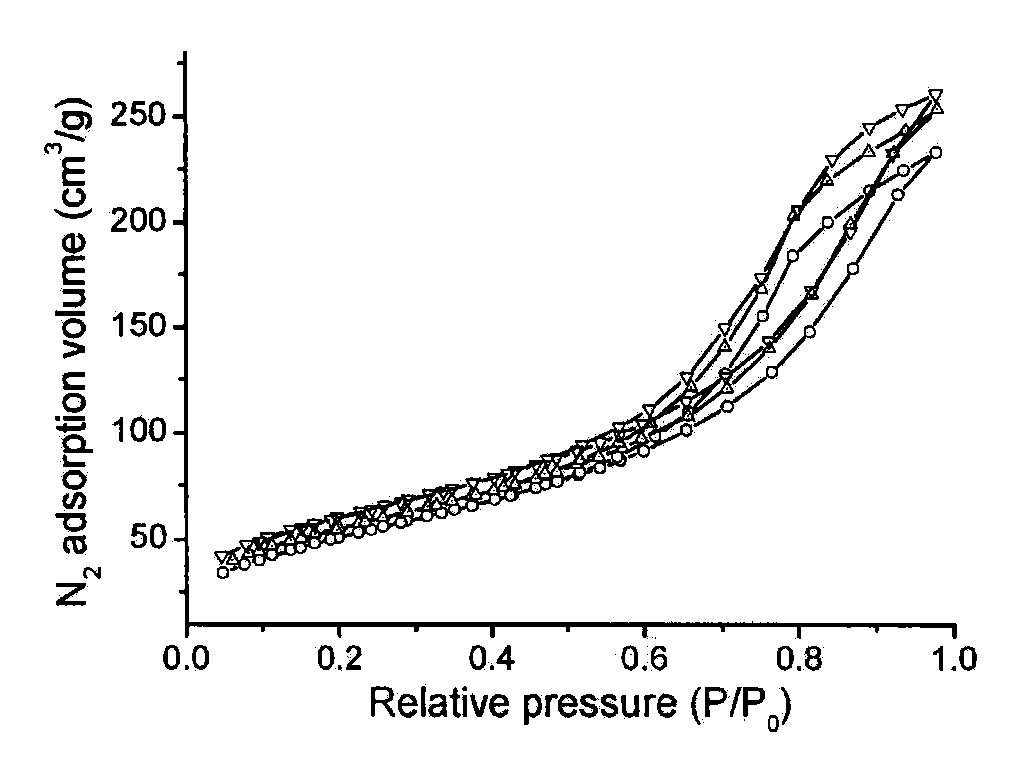

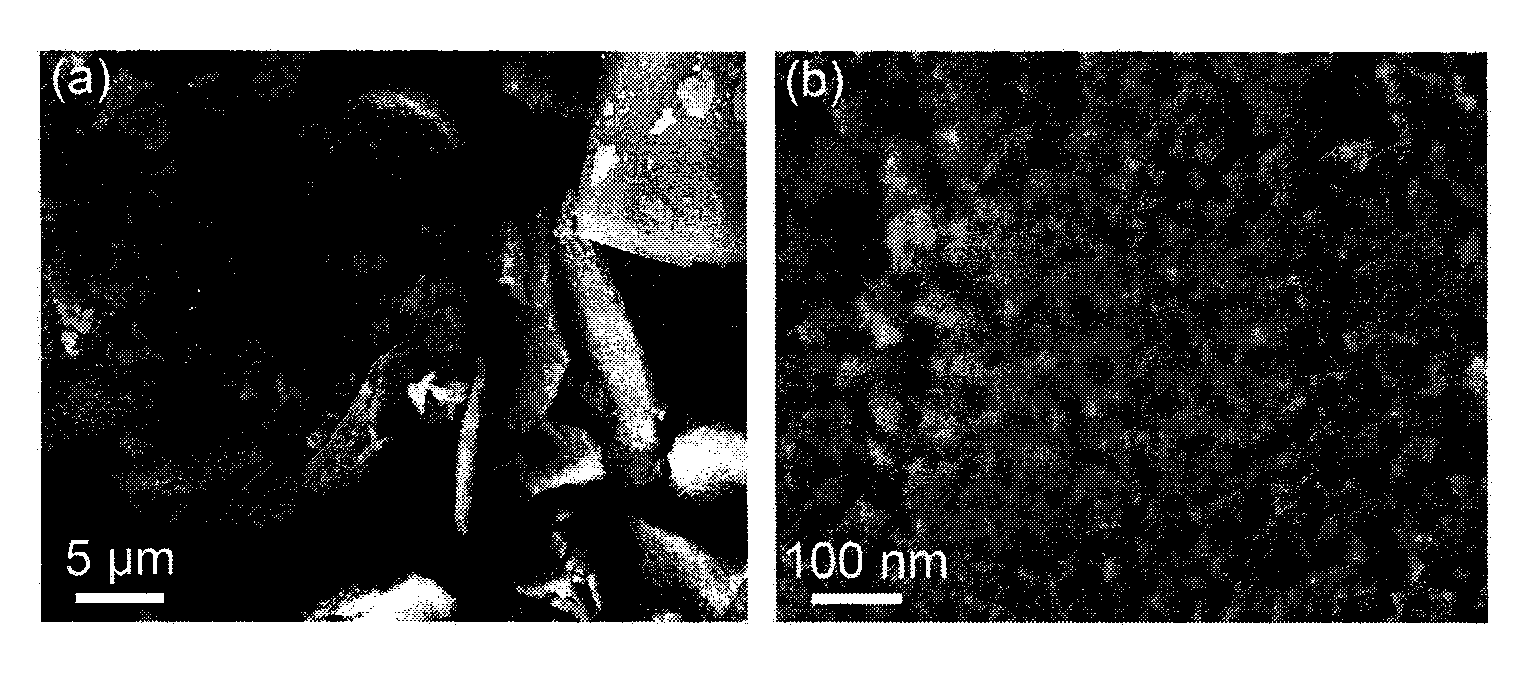

[0026] a. Sieve the vermiculite to 200 meshes, add 30% of the mass fraction into the 1mol / L hydrochloric acid solution, react for 6 hours, filter and wash to neutrality, and dry the filter cake at a temperature of 60°C for 12 hours. Grinding to obtain acidified exfoliated vermiculite, the acidified exfoliated vermiculite is a completely exfoliated lamellar structure with a surface rich in silanol;

[0027] b. Disperse 0.283 g of acidified exfoliated vermiculite in step a in 100 mL of deionized water, add 0.02 mol hydrochloric acid, and cool down to 1 °C;

[0028]c, tetra-n-butyl titanate is mixed with analytical pure ethanol solvent in a molar ratio of 1:30, and added to the acid solution containing acidified exfoliated vermiculite in step b to obtain [Ti] / [H + ] The molar ratio is 1: 2, the ratio of tetra-n-butyl titanate and acidified exfoliated vermiculite is the mixture of 35mmol / g, and the mixture is transferred to the reactor after continuing to stir for 3 hours at a tem...

Embodiment 2

[0042] a. Pass the vermiculite through a 300 mesh sieve, add 40% by mass fraction into a 2.5mol / L sulfuric acid solution, react for 6 hours, filter and wash until neutral, and dry the filter cake at a temperature of 100°C for 8 hours, The acidified exfoliated vermiculite is obtained by grinding, and the acidified exfoliated vermiculite is a completely exfoliated lamellar structure with a surface rich in silicon hydroxyl groups;

[0043] b. Disperse 0.331 g of acidified exfoliated vermiculite in step a in 50 mL of deionized water, add 0.03 mol hydrochloric acid, and cool down to 0.2 °C;

[0044] c, tetra-n-butyl titanate is mixed with analytical pure isopropanol solvent in a molar ratio of 1:35, and added to the acid solution containing acidified exfoliated vermiculite in step b to obtain [Ti] / [H + ] Molar ratio is 1: 3, the ratio of tetra-n-butyl titanate and acidified exfoliated vermiculite is the mixture of 30mmol / g, this mixture is transferred in the reaction kettle after c...

Embodiment 3

[0048] a. Pass the vermiculite through a 300 mesh sieve, add 20% by mass fraction into a 1.5mol / L phosphoric acid solution, react for 8 hours, filter and wash until neutral, and dry the filter cake at a temperature of 80°C for 8 hours, The acidified exfoliated vermiculite is obtained by grinding, and the acidified exfoliated vermiculite is a completely exfoliated lamellar structure with a surface rich in silicon hydroxyl groups;

[0049] b. Disperse 0.397 g of acidified exfoliated vermiculite in step a in 80 mL of deionized water, add 0.04 mol of hydrochloric acid, and cool down to 3 °C;

[0050] c, tetraisopropyl titanate is mixed with analytical pure ethanol solvent in a molar ratio of 1:10, and added to the acid solution containing acidified exfoliated vermiculite in step b to obtain [Ti] / [H + ] Molar ratio is 1: 4, the ratio of tetraisopropyl titanate and acidified exfoliated vermiculite is the mixture of 25mmol / g, this mixture is transferred in the reaction kettle after c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com