High frost resistance roller compacted concrete mortar wrapped stone mixing method

A technology of roller compacted concrete and high frost resistance, which is applied in the construction field of high frost resistance roller compacted concrete in cold regions, can solve the problem that the air content of high frost resistance roller compacted concrete cannot meet the requirements, and achieve the reduction of air-entraining agent dosage, Easy to control and increase the air content of RCC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The water-cement ratio is 0.30, the VC value of the machine mouth RCC is 2s, and the secondary sand ratio is 32, which meets the design requirements of the "Hydraulic Roller Compacted Concrete Construction Code" (DL / T5112-2009). %, the three-stage sand mixing rate is 28%, and the amount of glue is 130kg / m 3 For commonly used roller compacted concrete, the mixing method of plastic sand wrapped in stone is: use a forced mixer to mix in sections, first put in cementitious materials and sand materials, add admixture aqueous solution and stir for 2 minutes, then add stones and stir for 1.5 minutes.

Embodiment 2

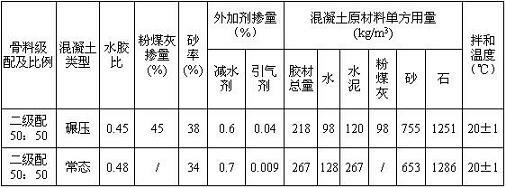

[0015] For the water-cement ratio of 0.45, the VC value of machine mouth RCC 5s, and the secondary sand ratio of 38, which meet the design requirements of the RCC mix ratio in the "Hydraulic Roller Compacted Concrete Construction Code" (DL / T5112-2009) %, the three-stage sand mixing rate is 33%, and the amount of glue is 240kg / m 3 The commonly used roller compacted concrete, the mixing method of plastic sand wrapped in stone is: using a forced mixer to mix in sections, when mixing, first put in cement, fly ash, sand, add admixture aqueous solution and stir for 2 minutes, then add stones and stir 1.5min.

Embodiment 3

[0017] For the water-cement ratio of 0.65, the VC value of machine-mouth RCC to be 8s, and the secondary sand ratio to be 43, which meet the design requirements of the RCC mix ratio in the "Hydraulic RCC Construction Code" (DL / T5112-2009) %, the three-stage sand mixing rate is 38%, and the amount of glue is 350kg / m 3 The commonly used roller compacted concrete, the mixing method of plastic sand wrapped stone is: use a forced mixer to mix in sections, when mixing, first put in cementitious material and sand, add admixture aqueous solution and stir for 3 minutes, then add stones and stir for 3.0 minutes .

[0018] The present invention will be described in detail below through specific test procedures.

[0019] 1. Research and development ideas

[0020] The mortar-wrapping method proposed by the present invention is based on the principle of air-entraining agent introducing air bubbles, changing the feeding sequence and mixing time of roller compacted concrete, and measuring t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com