Preparation method of 3,3'5,5'-tetraalkyl-4,4'-biphenyl diphenol

A technology of biphenyldiphenol and tetraalkyl, which is applied in 3 fields, can solve the problems of high requirements for reaction equipment and harsh reaction conditions, and achieve the effects of high oxygen utilization rate, no discharge of three wastes, and simple reaction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

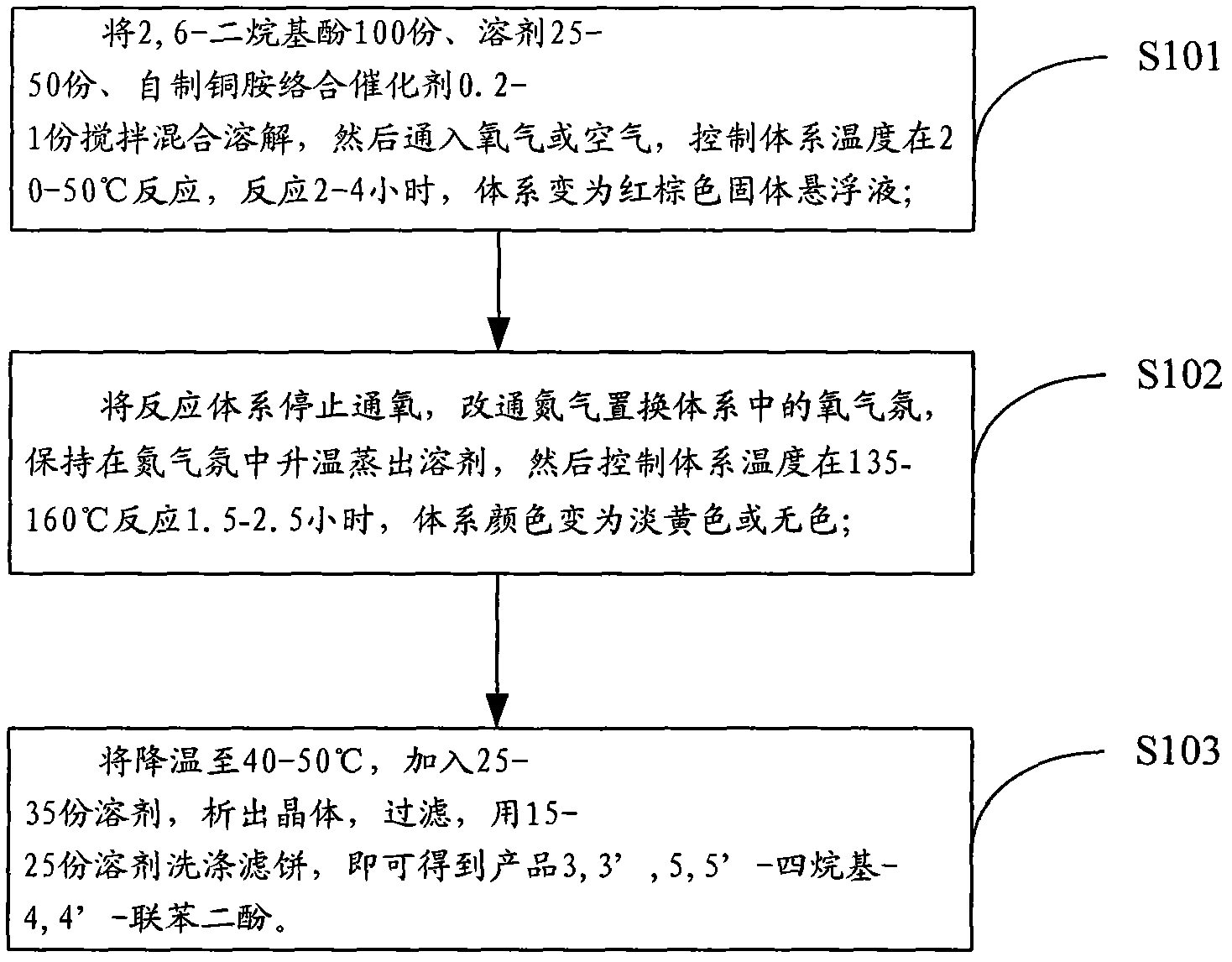

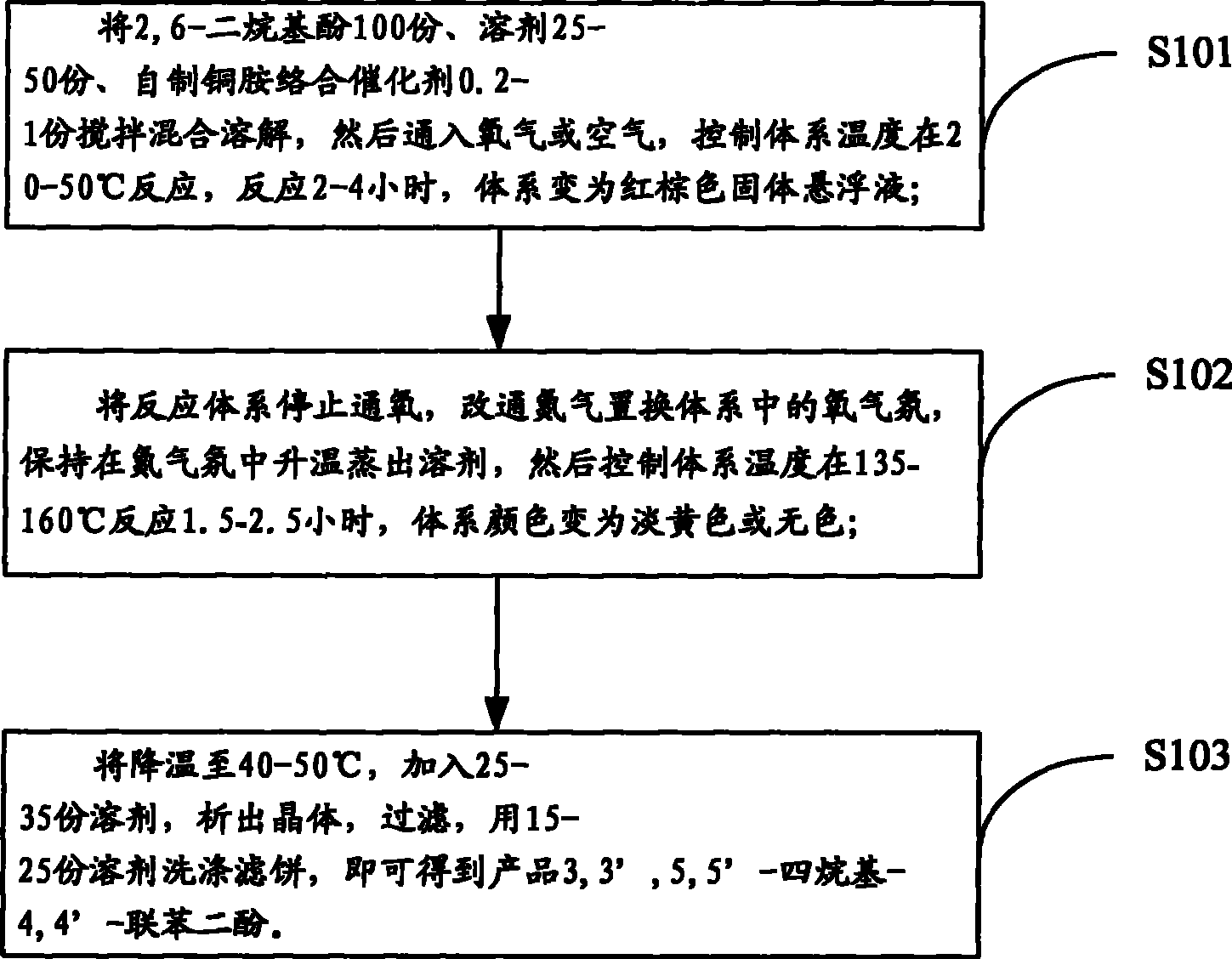

[0025] figure 1 It shows the realization process of the preparation method of 3,3',5,5'-tetraalkyl-4,4'-biphenyldiol provided by the embodiment of the present invention. The preparation method comprises the following steps:

[0026] In step S101, 100 parts of 2,6-dialkylphenol, 25-50 parts of solvent, and 0.2-1 part of self-made copper amine complex catalyst were stirred, mixed and dissolved, and then oxygen or air was introduced to control the temperature of the system at 20- React at 50°C for 2-4 hours, the system turns into a reddish-brown solid suspension;

[0027] In step S102, the reaction system in the above step S101 is stopped from passing oxygen, the oxygen atmosphere in the nitrogen replacement system is replaced, the solvent is kept in the nitrogen atmosphere, and the temperature is raised to evaporate the solvent, and then the temperature of the system is controlled at 135-160°C for 1.5-2.5 hours. , the color of the system becomes pale yellow or colorless;

[0...

Embodiment 1

[0031] 100g of 2,6-dimethylphenol, 25g of methanol, and 0.2g of the catalyst obtained in Example 1 of the self-made copper amine complex catalyst were stirred, mixed and dissolved, and then oxygen was introduced at a rate of 60ml / min, and the temperature of the system was controlled at 20-30°C After 2 hours of reaction, the system turned into a reddish-brown solid suspension. The reaction system stopped passing oxygen, and replaced the oxygen atmosphere in the system with nitrogen. Keep in a nitrogen atmosphere and heat up to about 65°C to evaporate the solvent, then raise the temperature to 135-145°C for 1.5 hours, cool down to 40°C, add 25g of methanol, precipitate crystals, filter, and wash the filter cake with 25g of methanol to obtain Off-white product 3,3',5,5'-tetramethyl-4,4'-diphenol 70g, melting point 224-227°C, product purity 98.52%.

preparation Embodiment 2

[0033] 2,6-Di-tert-butylphenol 100g, ethanol 40g, self-made copper amine complex catalyst embodiment 2 obtained catalyst 0.5g are stirred and mixed to dissolve, then pass into oxygen with the speed of 30ml / min, control system temperature at 30-40 °C for 3 hours. Stop the oxygen flow, and change the oxygen atmosphere in the nitrogen replacement system. Keep in a nitrogen atmosphere and raise the temperature to about 80°C to evaporate the solvent, then control the system temperature at 145-150°C for 2 hours, the color of the system will become light to light yellow. Cool down to 45°C, add 30g of ethanol, precipitate crystals, filter, and wash the filter cake with 20g of ethanol to obtain the light yellow product 3,3',5,5'-tetra-tert-butyl-4,4'-biphenyl Phenol 68g, melting point 186-187°C, high performance liquid chromatography analysis product purity is 99.18%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap