Antibacterial paper and production technology thereof

A production process and technology of antibacterial paper, applied in the field of antibacterial paper and its production process, can solve the problems of reducing the degree of freedom of selection of antibacterial agents, increasing the coating process, and increasing the cost of paper production, so as to broaden the degree of freedom of choice and reduce production. cost, avoidance of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

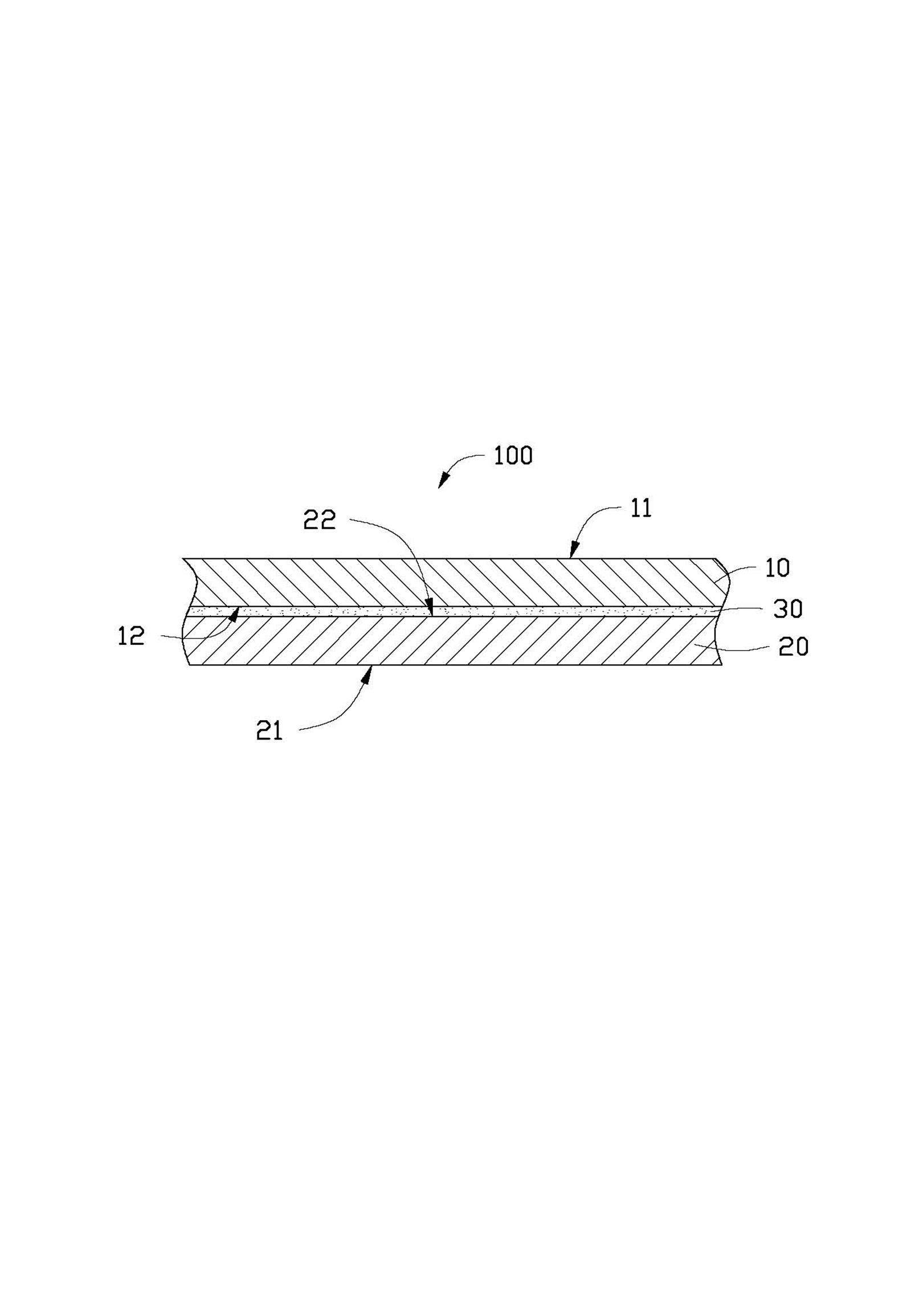

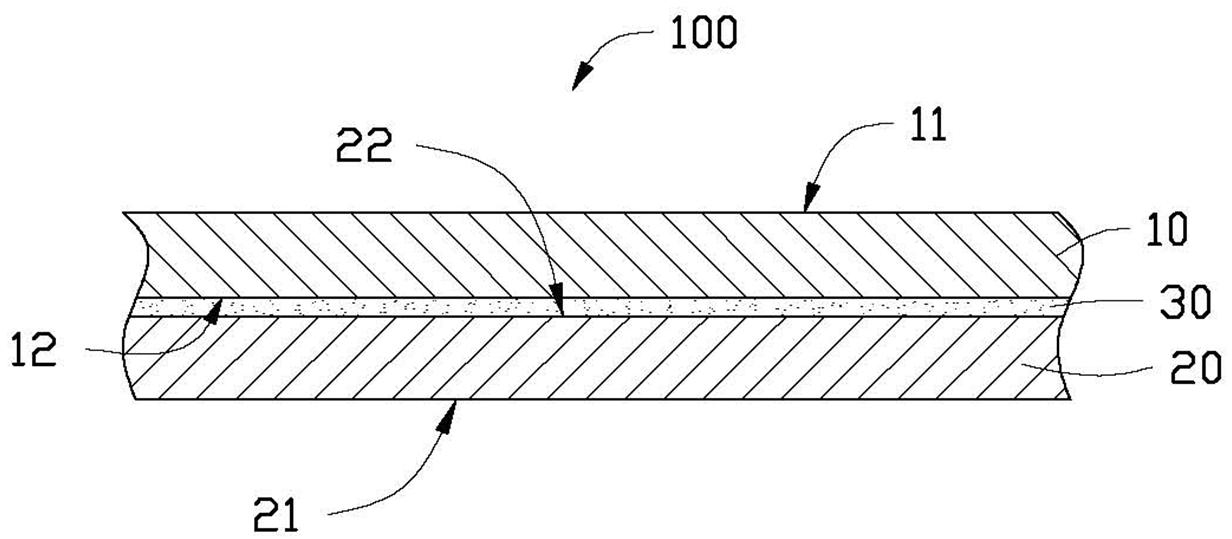

[0014] See figure 1 , the antibacterial paper 100 provided by the present invention comprises a first paper layer 10 , a second paper layer 20 and an antibacterial layer 30 located between the first paper layer 10 and the second paper layer 20 .

[0015] In this embodiment, both the first paper layer 10 and the second paper layer 20 are single-layer paper, and the first paper layer 10 has a first outer surface 11 exposed to the outside and is connected to the first outer surface. 11 opposite to the first contact surface 12, the second paper layer 20 has a second outer surface 21 exposed to the outside and a second contact surface 22 opposite to the second outer surface 21, the first paper layer The layer 10 and the second paper layer 20 are laminated to each other via the first contact surface 12 and the second contact surface 22 .

[0016] The antibacterial layer 30 is formed between the first contact surface 12 and the second contact surface 22 . The antibacterial layer 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com