Adjustable cylindrical mold reinforcing device

A reinforcement device and column-shaped technology, which is applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problems of complicated operation, high cost, slow progress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

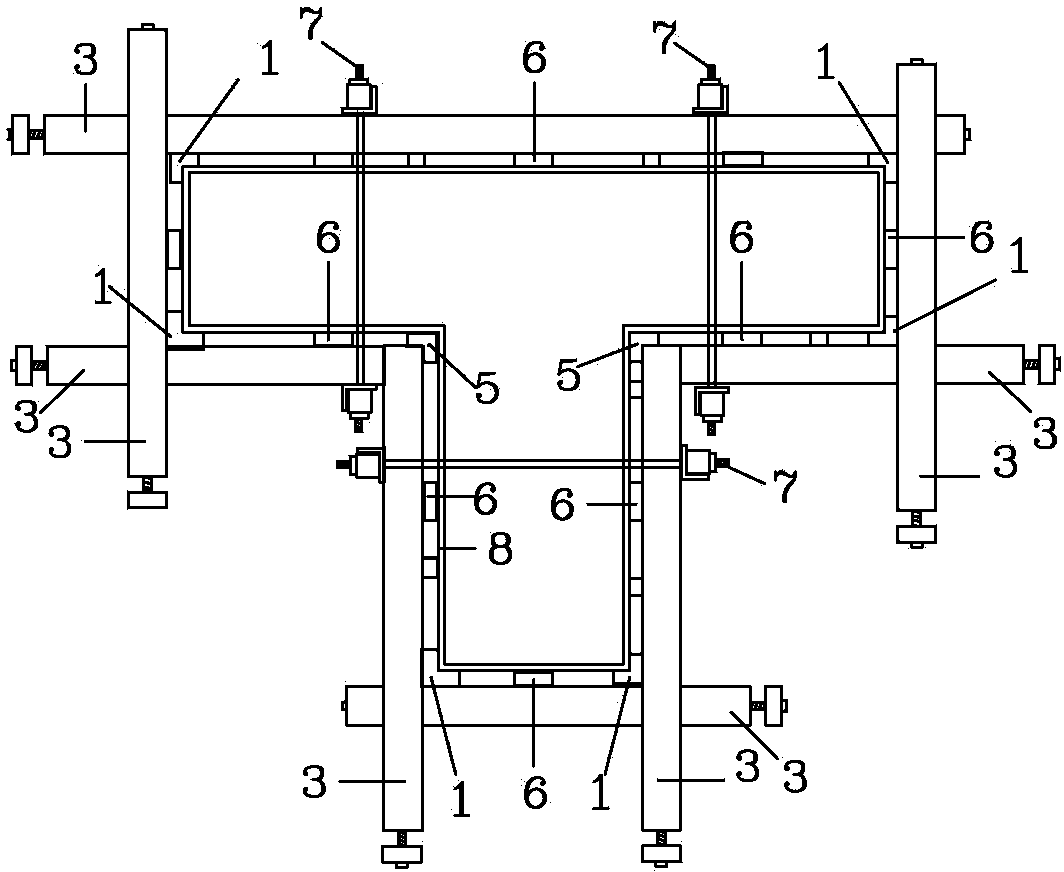

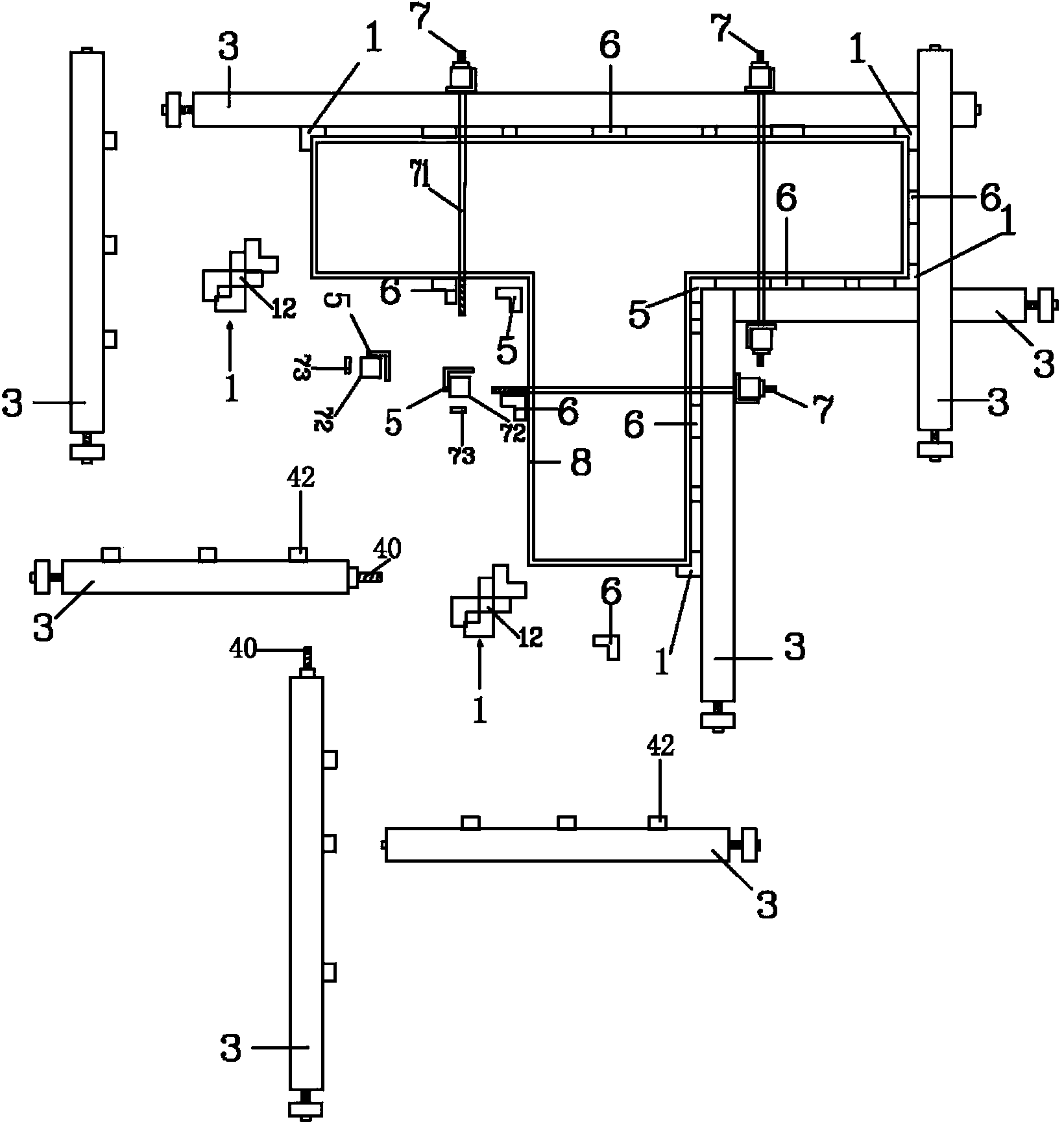

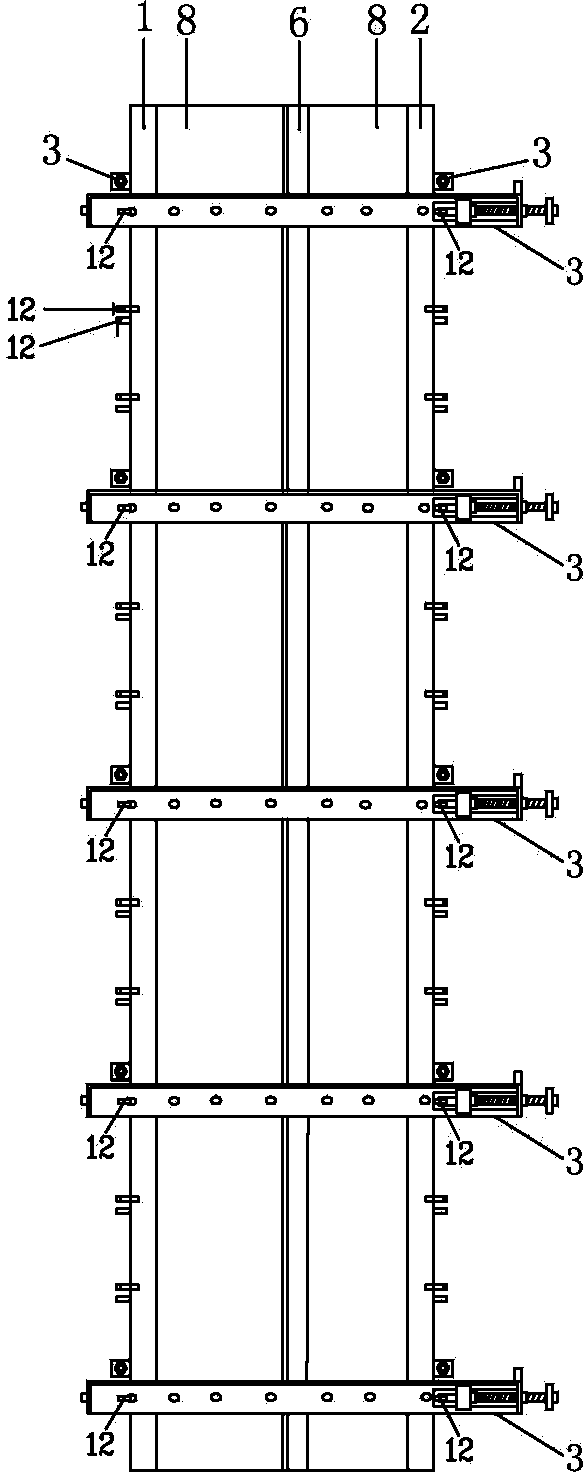

[0027] like Figure 1 to Figure 11 As shown, the present invention provides a reinforcement device for a cylindrical mold, which mainly includes several male corner corner protectors 1, which longitudinally enclose the male corners of the cylindrical mold 8 (not shown); Corner corner protectors 5, which longitudinally enclose the internal corners of the cylindrical mold 8 (not shown in the figure); several pressing plate reinforcements 6, which are longitudinally fixed between the cylindrical mold 8 and the pull bar 3 In between, a plurality of pull rods 3, said several pull rods 3 are staggered in pairs on the outside to surround the male corner corner protector 1, the female corner protector 5, the pressure plate encryption part 6, the combined groove buckle screw rod 7, and the pair of cylindrical The mold 8 forms an enveloping reinforcement. A plurality of groove buckles 72 and screw rods 71, each of the screw rods 71 passes through two adjacent karaoke rods 3 respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com