Assembly method of non-return device

An assembly method and backstop technology, applied to clutches, one-way clutches, mechanical equipment, etc., can solve the problems of reduced assembly efficiency, inability to insert, difficulties, etc., to ensure production efficiency, increase assembly speed, and high pass rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

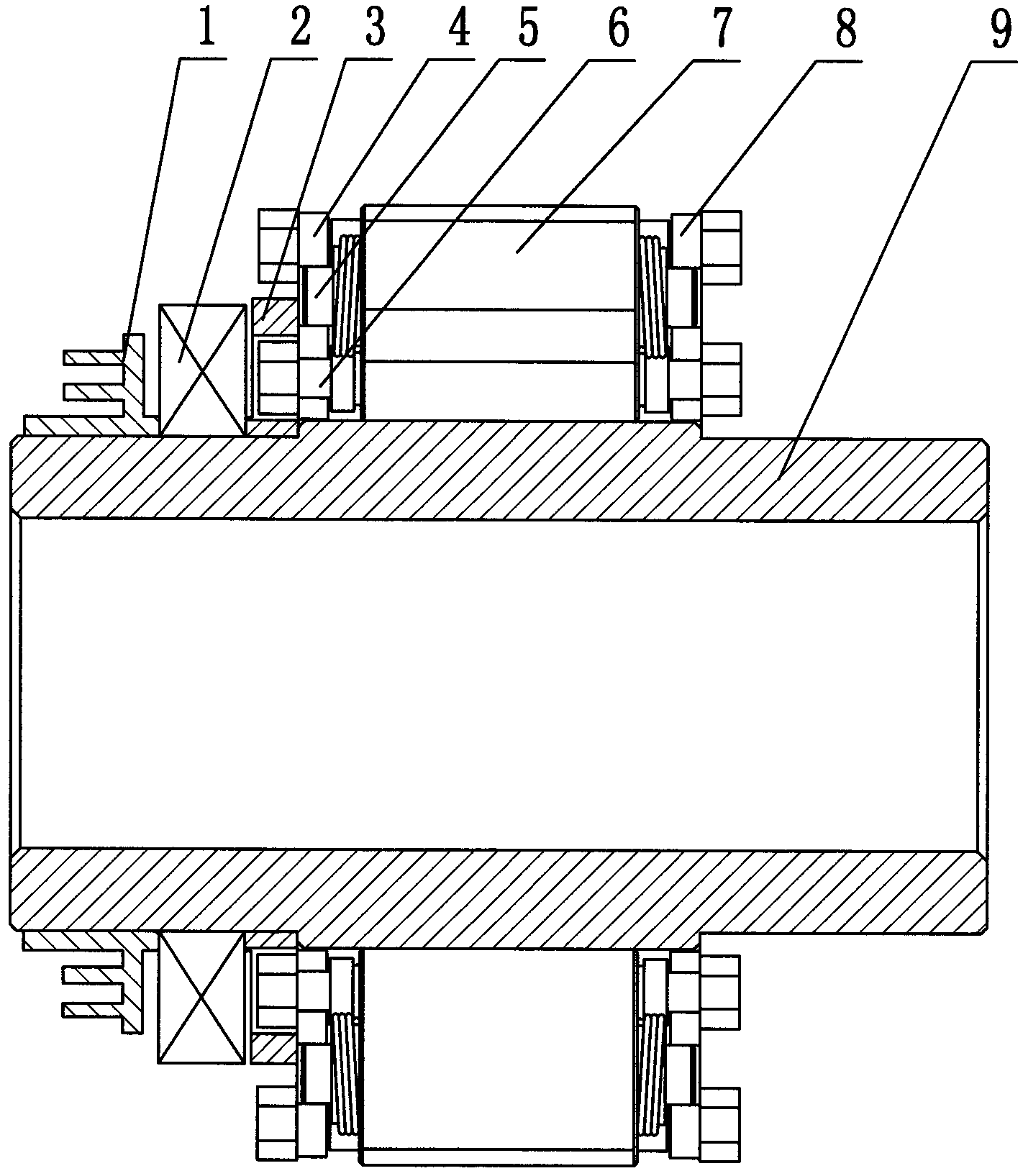

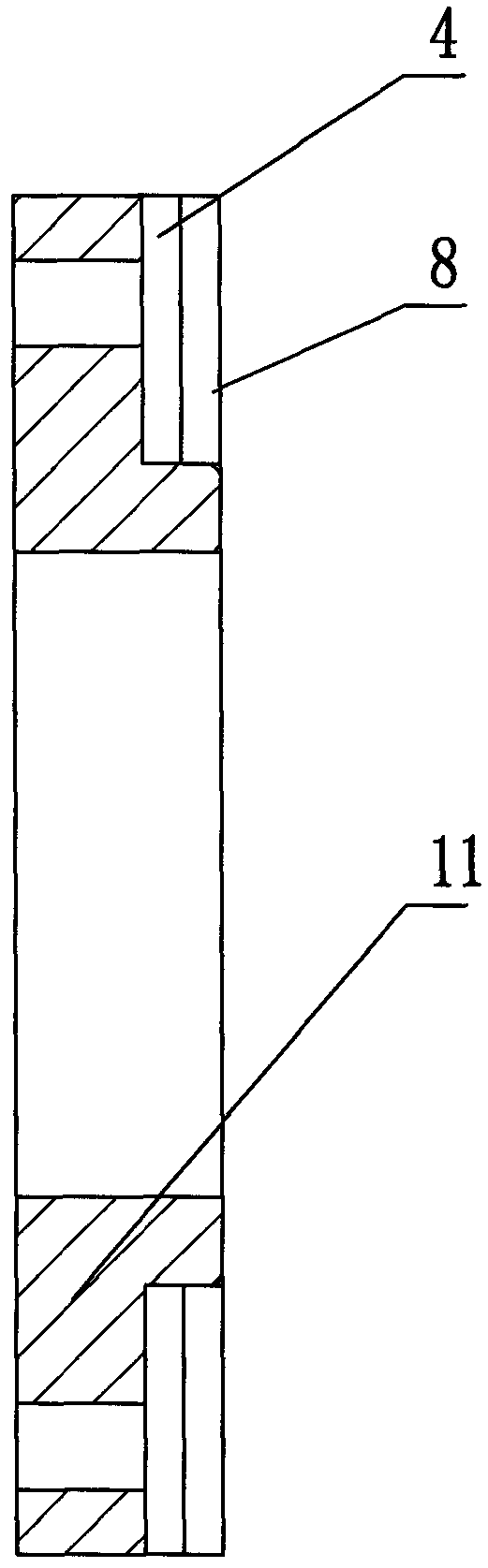

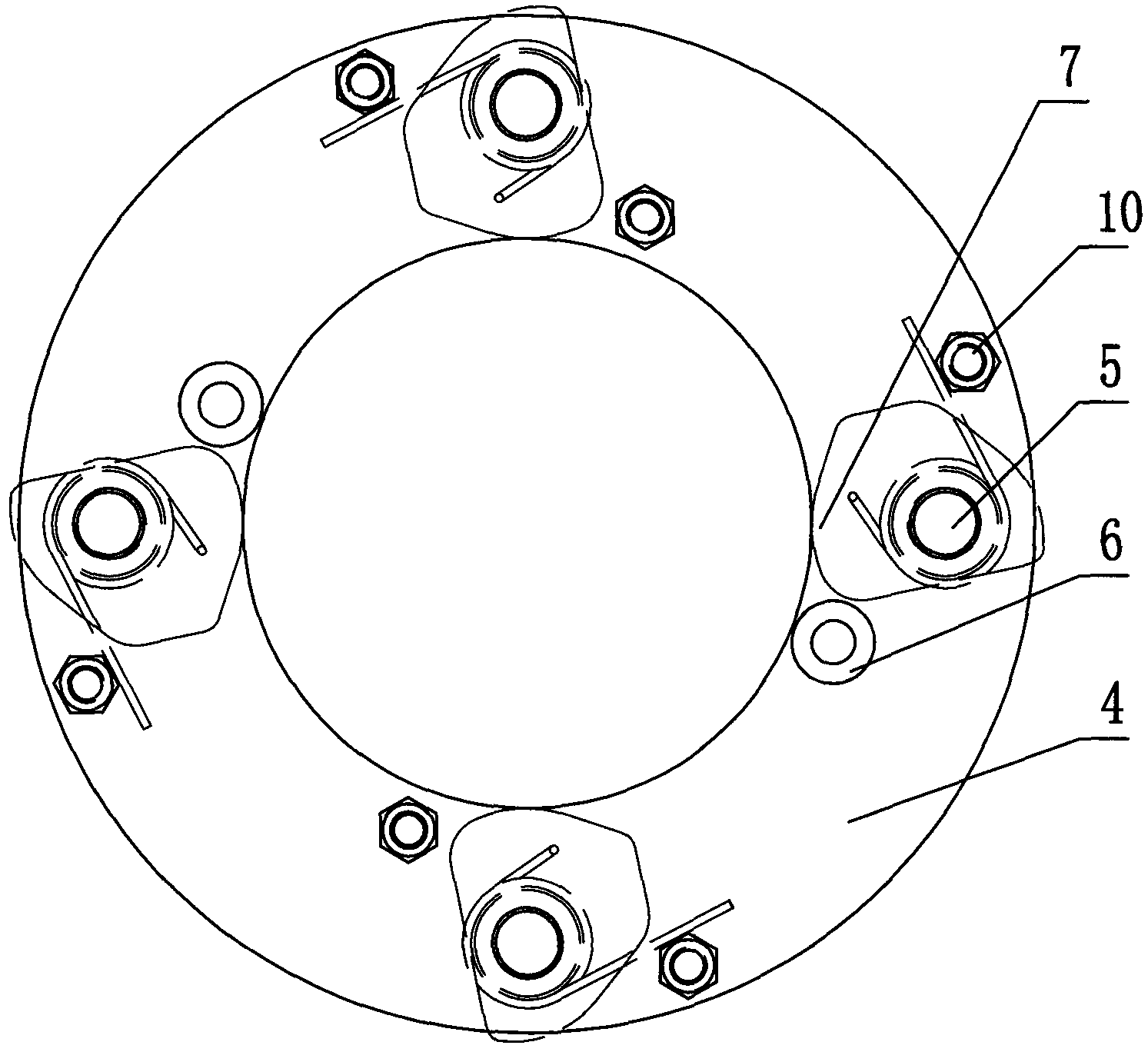

[0018] Referring to the accompanying drawings, in the assembly method of this backstop, the backstop includes two side plates 4, 8, a roller assembly, a connecting plate 3, an inner sealing ring 1, a bearing 2 and an inner sleeve 9, wherein the roller The assembly is installed between the two side plates 4, 8, the roller assembly includes a cam 7, a camshaft 5, a retaining post 6, and a stud 10, and the cam 7 is installed between the two side plates 4, 8 through the camshaft 5 , at the same time, the two side plates 4 and 8 are also connected by retaining columns 6 and studs 10. When assembling, the two side plates 4 and 8 are spot welded together earlier, put on a mold 11, and the two sides are connected by a drilling mold. The plates 4 and 8 are simultaneously drilled, and the drill holes include the retaining column installation hole, the cam installation hole and the stud hole, and the same marks are marked on the positions where the two side plates 4 and 8 are drilled simu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com