Glue discharging furnace

A technology for debinding furnace and furnace wall, applied in the field of debinding of chip electronic components, can solve the problems of different process performance, large difference in the amount of glue removal, uneven air intake, etc., to ensure consistency, manufacturing// The effect of low renovation cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the accompanying drawings and in combination with preferred embodiments.

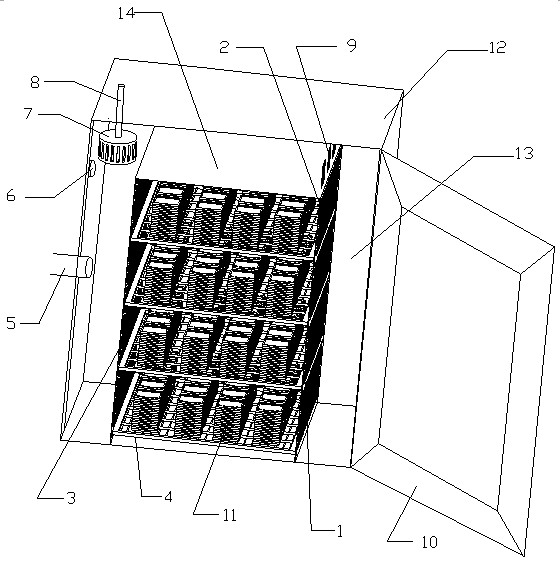

[0019] like figure 1 As shown, the debinding furnace of the present embodiment includes a furnace wall 12, a furnace door 10, a furnace wall 12 and a furnace door 10 to form a furnace 13, a blower 7 and a heater 9, and the furnace 13 is used to place electronic components to be deglued. The left furnace wall 12 is provided with an air inlet 6 and an air outlet 5, wherein the air inlet 6 is arranged on the top of the left furnace wall 12 and is close to the top of the furnace wall for introducing fresh air into the furnace under the action of the blower 7, The air outlet 5 is set in the middle part of the furnace wall 12 on the left side, and its external exhaust device is used to suck away the flue gas produced by debinding. The blower 7 is set on the top left side of the furnace 13 near the air inlet 6. The motor output shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com