Model construction and evaluation method for service life and reliability of product under outfield circumstance

A reliability and product technology, applied in the field of life and reliability evaluation, can solve problems such as difficult evaluation work and scarce field information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

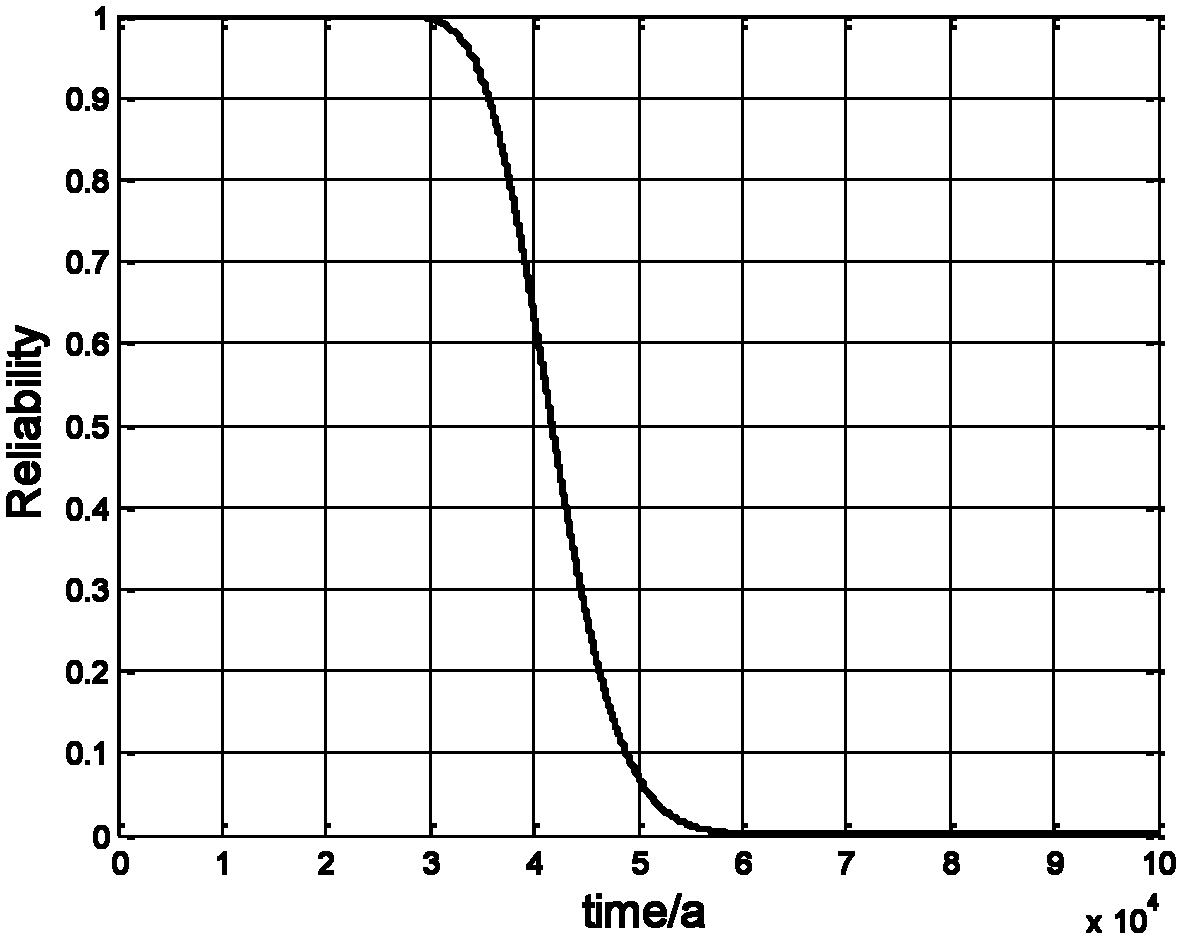

[0112] If a temperature step stress accelerated degradation test is carried out on a photoelectric product, the sample size is 4, the temperature stress level is 4, the temperature is 60°C, 80°C, 100°C, 120°C; the test time for each stress level is 1250 , 750, 500, 500 hours; the product performance testing time interval Δt is 5 hours. At the same time, a product is used in the field at a temperature of 25°C, and its data has been collected for 5,000 hours. The product's performance testing time interval Δt is 5 hours. Select optical power as its performance parameter, the initial value of optical power y 0 is 100, and the parameter failure threshold l is 40. It is necessary to evaluate the reliability of the product under field conditions for 3 years and the life of the product when the reliability is 0.95.

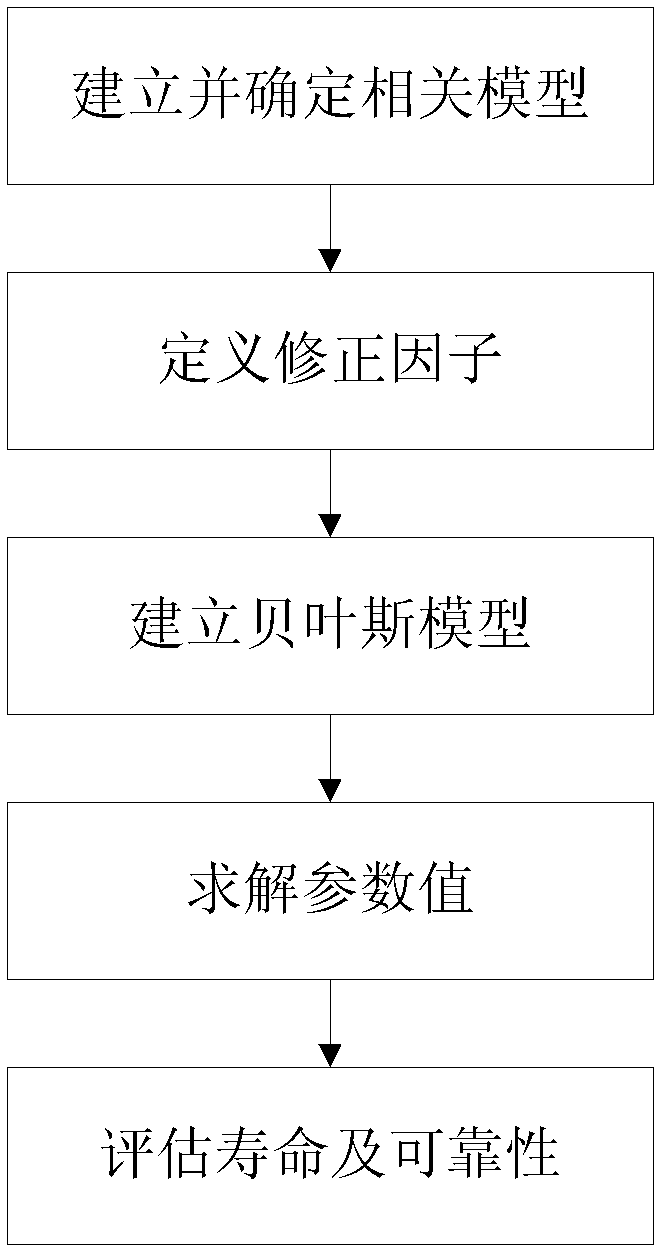

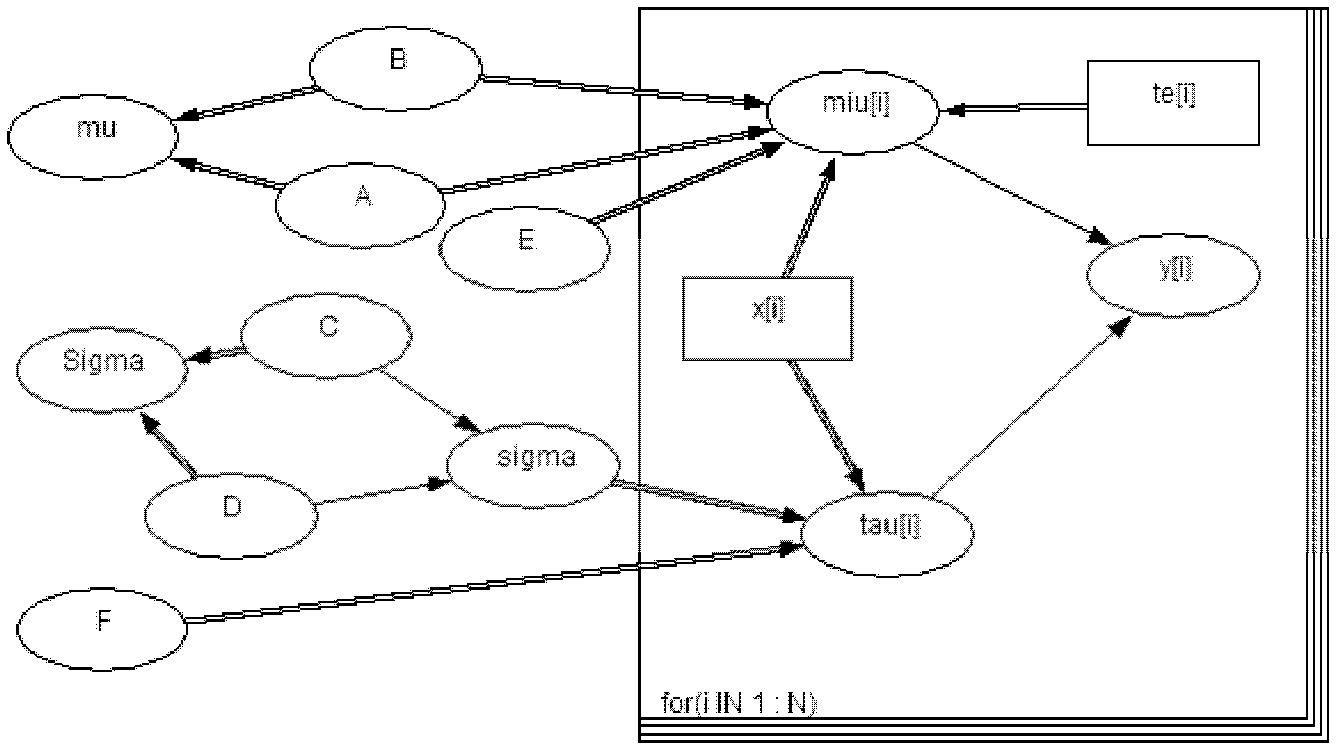

[0113] Step 1. Establish and determine relevant models

[0114] Since the stress applied to the product is temperature, the Arrhenius model is selected as the acceler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com