Method for manufacturing resonant cavity light emitting diode

A technology for light-emitting diodes and manufacturing methods, which is applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., and can solve problems such as alignment errors, increased series resistance, and poor light-emitting efficiency of resonant cavity light-emitting diodes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The foregoing and other technical contents, features and effects of the present invention will be clearly understood in the following detailed description of preferred embodiments with reference to the drawings.

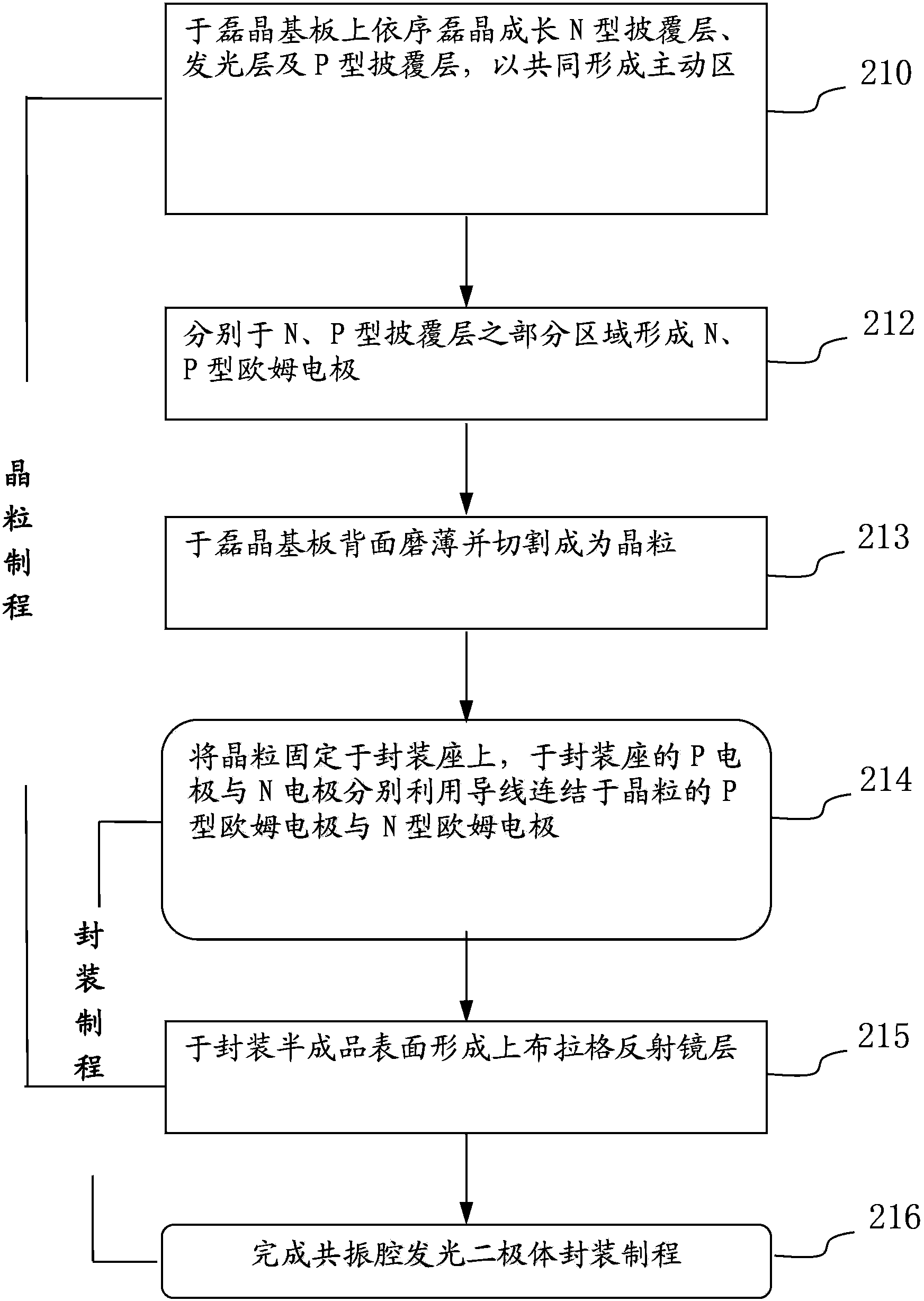

[0067] The first preferred embodiment of the method for manufacturing a resonant cavity light-emitting diode of the present invention can simplify the manufacturing process of the upper Bragg reflector layer, and the upper Bragg reflector layer can be formed on the light-emitting diode without an alignment step The light-extracting area of the body, and a resonant cavity light-emitting diode with high light-extracting efficiency is manufactured.

[0068] refer to figure 2 Step 211 is performed to sequentially epitaxially grow the lower Bragg reflector layer 31, the N-type cladding layer 32, the light-emitting layer 33 and the P-type cladding layer 34 on the epitaxial substrate 30, so as to jointly form the active region 3, as image 3 shown. The epitaxial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com