A kind of organic light-emitting display device and preparation method thereof

A light-emitting display, organic technology, used in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of affecting the yield of the screen body, easy to open circuit, etc., to increase current, avoid open circuit, small metal The effect of thin film surface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

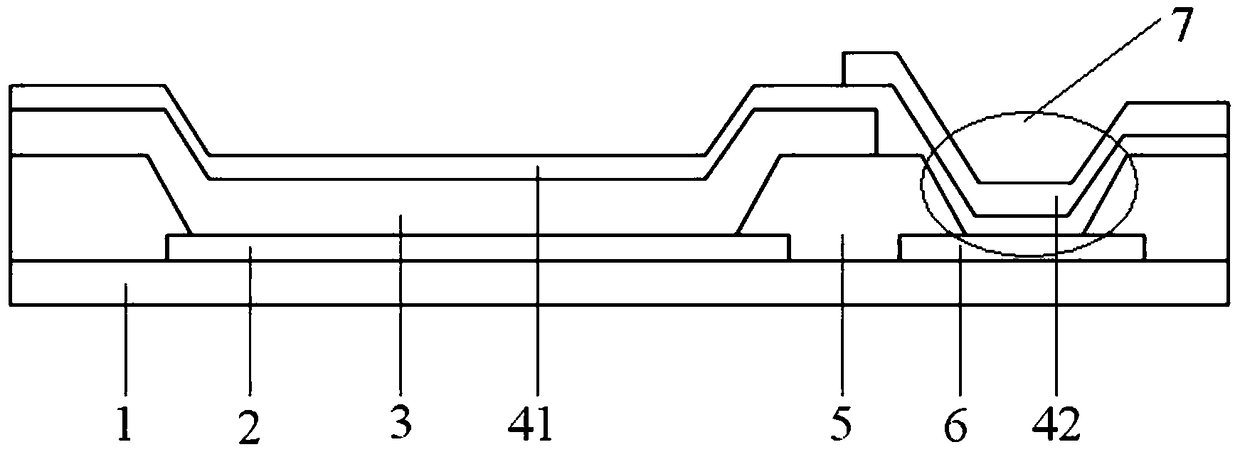

[0031] The organic light-emitting display device provided in this embodiment, as attached figure 1 As shown, it includes a pixel layer arranged on a substrate 1, the pixel layer includes several organic light emitting diodes arranged in an array (only one organic light emitting diode is shown in the figure for clarity), and the organic light emitting diode includes sequentially The anode layer 2 , the organic layer 3 and the first cathode layer 41 are stacked.

[0032] The organic light-emitting display device also includes a cathode lead 6, and an insulating layer 5 arranged between the first cathode layer 41 and the cathode lead 6, and the insulating layer 5 is provided with a wire for conducting the first cathode layer. 41 and the contact hole 7 for the cathode lead 6.

[0033] The second cathode layer 42 is directly arranged on the non-opening area of the first cathode layer 41, and the projection of the second cathode layer 42 on the plane where the anode layer 2 is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com