Cu-ni-si based alloy with excellent bendability

A cu-ni-si, bending technology, applied in the direction of metal/alloy conductors, conductive materials, conductive materials, etc., can solve the problems of poor bendability, low alloy strength, etc., to achieve excellent bending workability, no wrinkles The effect of the appearance of the curved part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

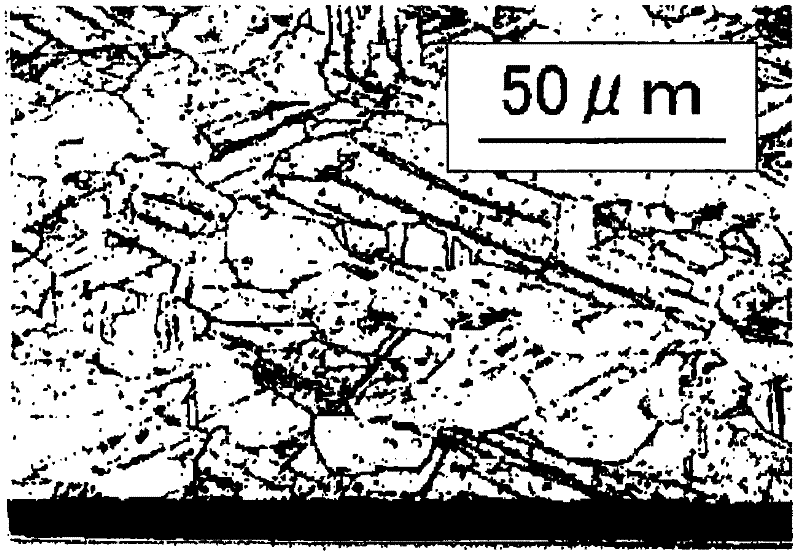

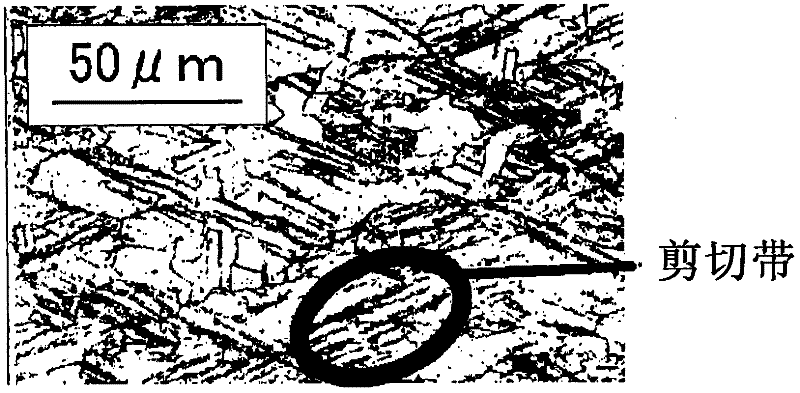

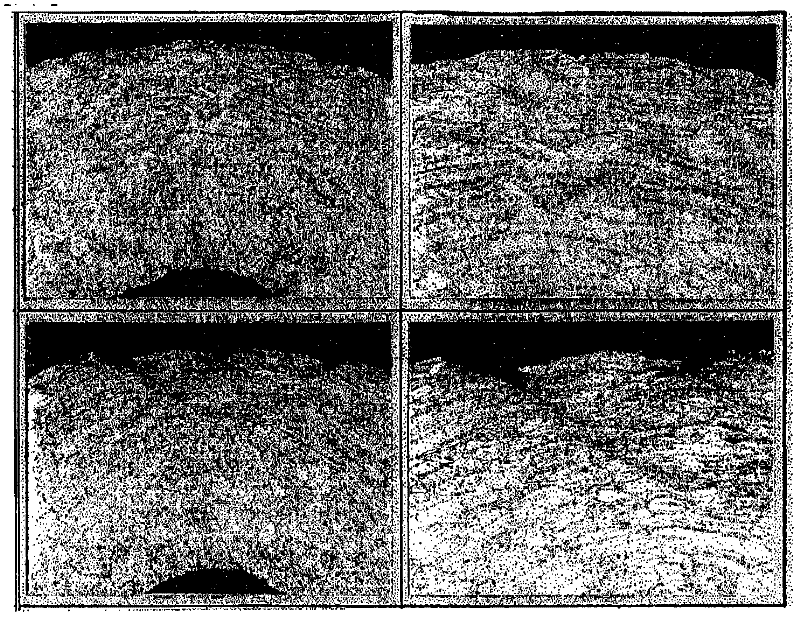

Image

Examples

Embodiment

[0073] The following shows the results of the production examples and characteristic tests of the Cu-Ni-Si alloy of the present invention, but it should be understood that they are provided for a better understanding of the present invention and its advantages, and do not mean that the present invention limited.

[0074] (Manufacturing method)

[0075] Copper alloys composed of various components are melted in a high-frequency melting furnace, and an ingot with a thickness of 20 mm, a width of 50 mm, and a length of 150 mm is cast. Next, in order to fully dissolve Ni and Si in the matrix, the ingot is heated at a heating temperature of 800° C. Calender until the thickness is 8mm. Next, face cutting is performed to remove scale on the surface, and then rolled to a predetermined thickness.

[0076] Next, after performing solution treatment at a temperature of 850 to 950°C for 10 minutes depending on the plate thickness, each average cooling rate in the ranges of solution temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap