Volute type walnut shell breaking machine with beating rotary drum

A volute type shell breaking machine technology, which is applied in the field of walnut shell breaking machines and volute type walnut shell breaking machines, can solve the problems of increasing the user's initial investment, later use and maintenance costs, limiting the popularization and application of walnut shell breaking machines, Uneven size of walnuts and other problems, to achieve the effect of ensuring relative integrity, novel shell breaking method, and reliable working method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

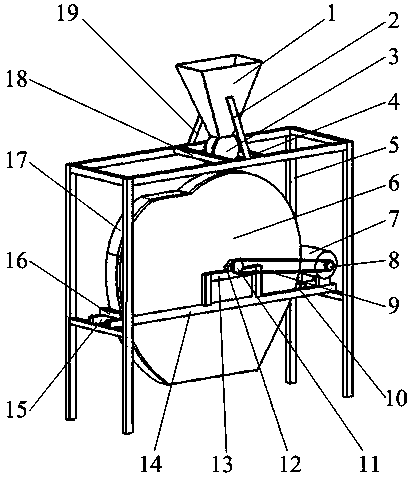

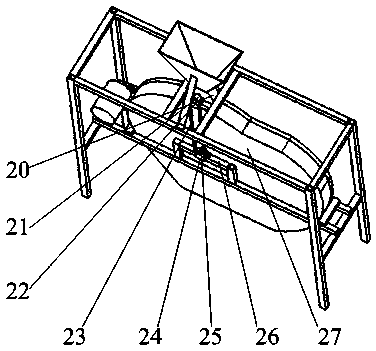

[0027] refer to figure 1 , figure 2 , The main frame 5 of the present embodiment is equipped with a turntable type feeding device, a rotating drum type pumping shell breaking device, a volute type secondary impact and discharge device, and a power transmission device.

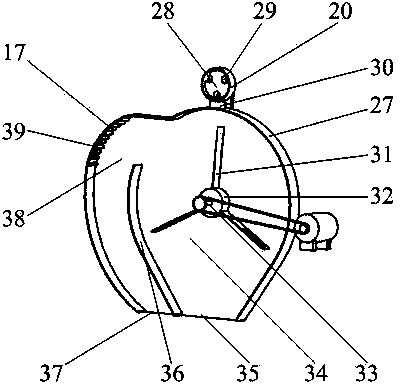

[0028] refer to Figure 1 to Figure 4 and Figure 6, the turntable feeding device of the present embodiment includes feeding hopper 1, support plate I 2, support plate II 19, feeding turntable 28, feeding turntable cover I 3, feeding turntable cover II 20, feeding rotating shaft 40, Bearing and bearing seat 21, feeding turntable support I 4, feeding turntable support II 18 and connecting pipe 30, feeding hopper 1 is fixed on the table top of main frame 5 through support plate I 2 and support plate II 19, and one end of feeding rotating shaft 40 is fixed The feeding turntable 28 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com