Double-layer wind-proof umbrella

A wind-proof, double-layer technology, applied in the direction of walking sticks, etc., can solve the problems of easy collapse, unsuitable for use, hindering opening, and smoothness of the umbrella, so as to achieve the effect of enhancing support.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

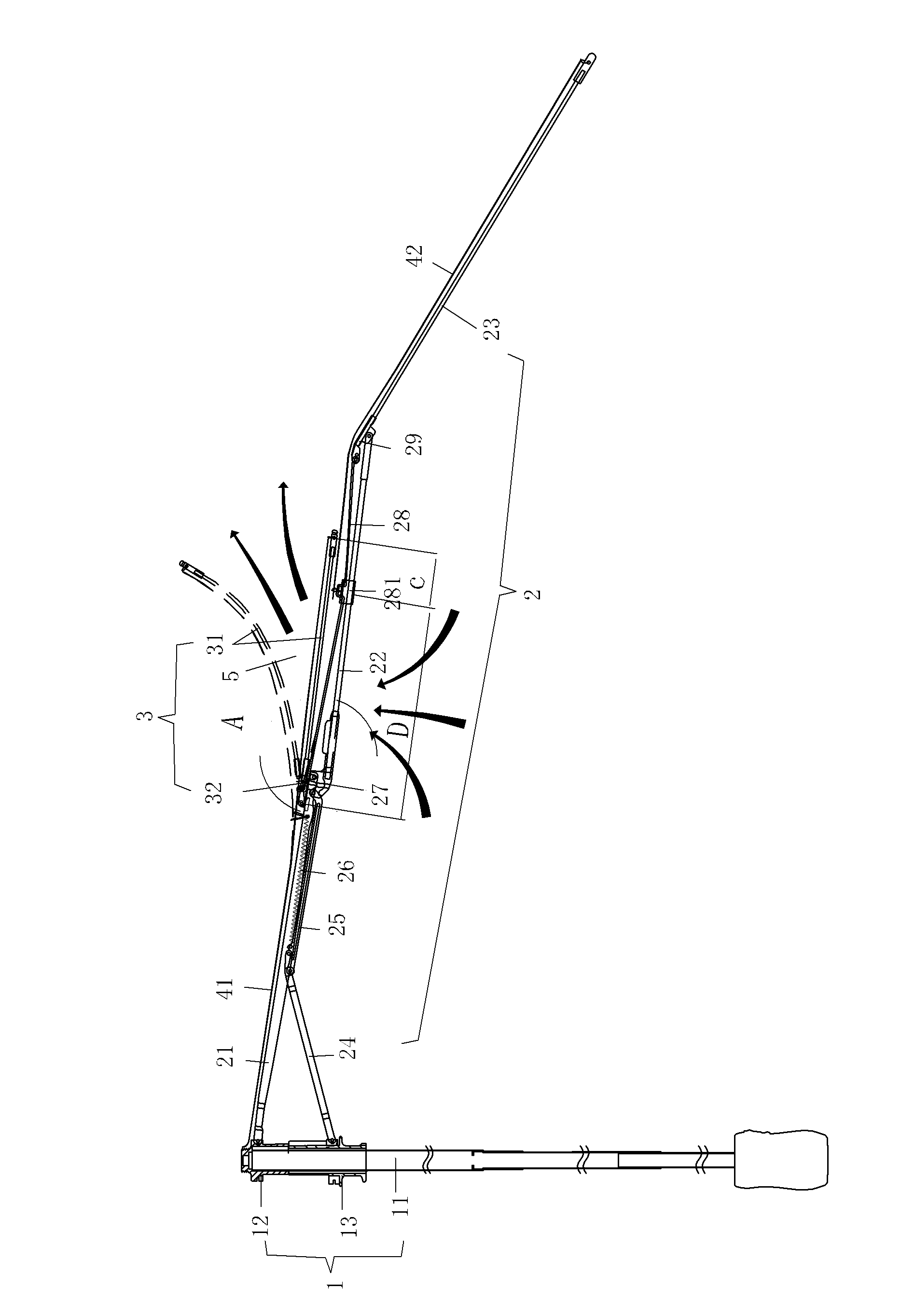

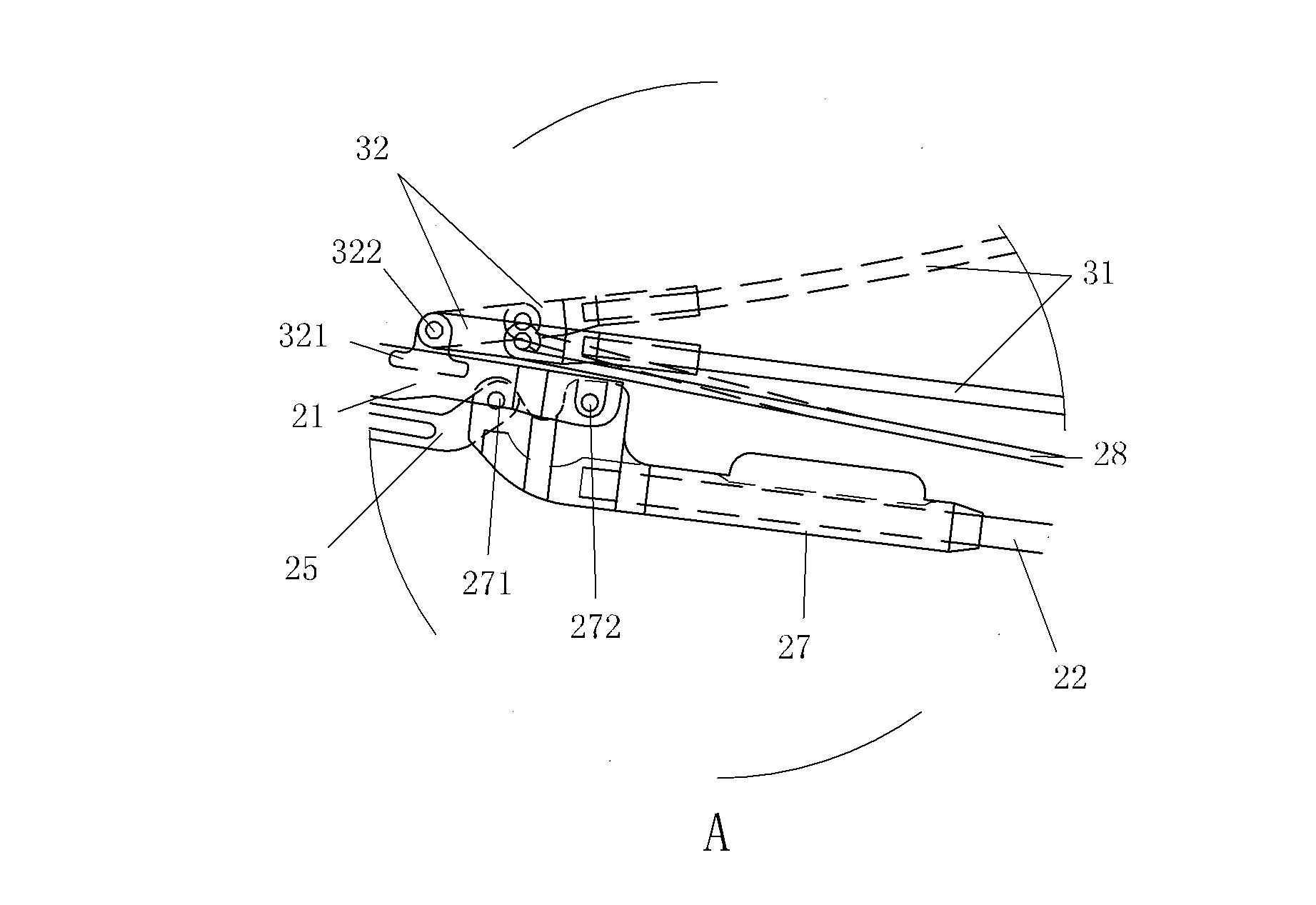

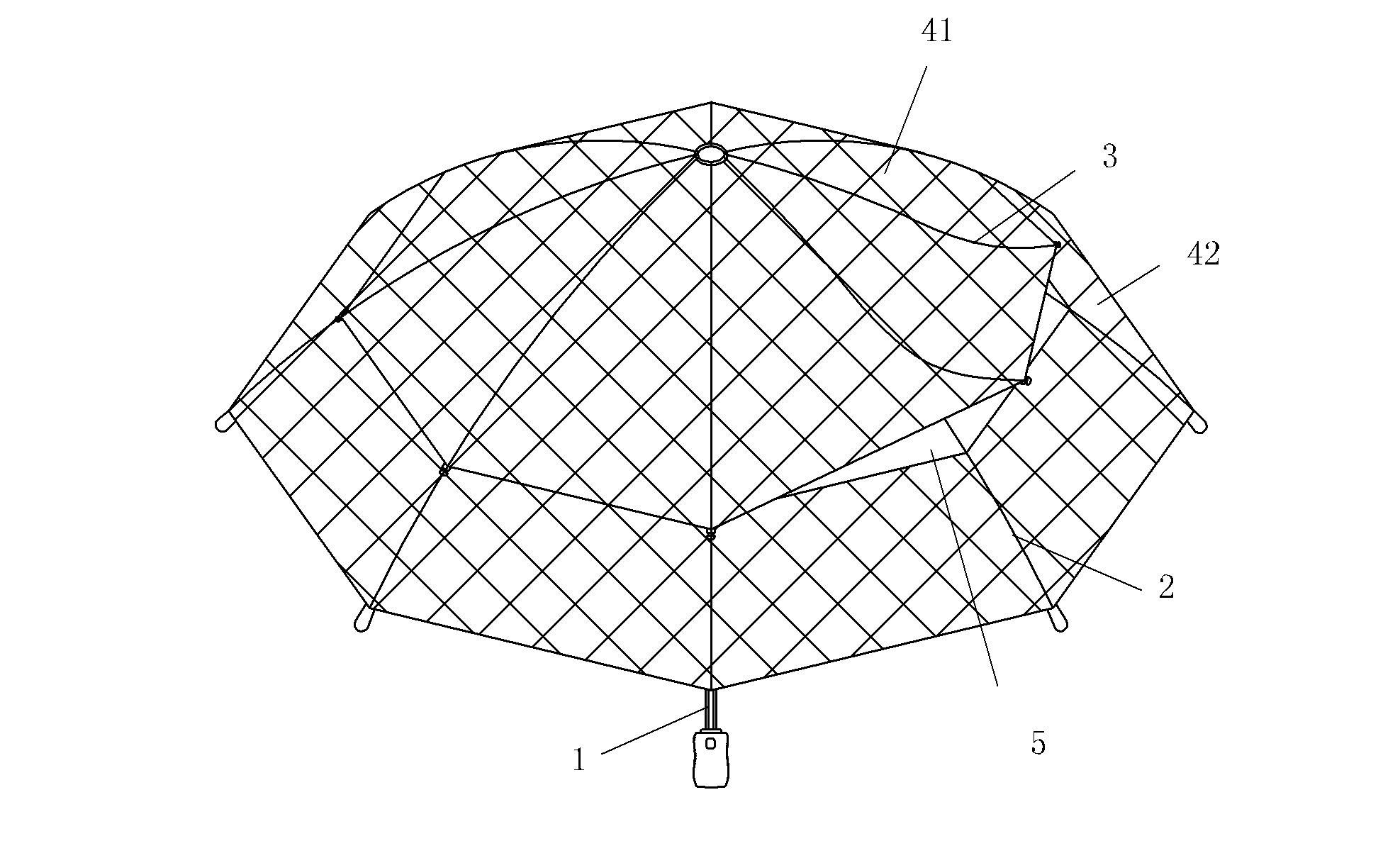

[0029] The structure of an embodiment of the double-layer windproof umbrella of the present invention, as figure 1 and Figure 12 As shown, the upper end of the telescopic rod 11 of the middle rod 1 of the double-layer windproof umbrella is fixed with an upper nest 12, and the outer circumference of the telescopic rod 11 of the middle rod 1 is slidably sleeved with the lower nest 13. Multiple groups of umbrella rib assemblies 2 are pivotally connected to the upper nest 12 and the lower nest 13 along the circumference of the upper nest 11 and the circumference of the lower nest 13 . The polygonal upper umbrella cloth 41 is tied to the center position of the outer sides of each group of umbrella rib assemblies 2 . The annular lower umbrella cloth 42 is tied to the outer periphery of each group of umbrella rib assemblies 2 . A control valve positioned between the upper umbrella cloth 41 and the total surface of the umbrella ribs is set at each group of umbrella rib assemblies 2...

Embodiment 2

[0039] The structure of another embodiment of the double-layer windproof umbrella of the present invention, as Figure 13 and Figure 16 As shown, the upper end of the telescopic rod 11 of the middle rod 1 of the double-layer windproof umbrella is fixed with an upper nest 12, and the outer circumference of the telescopic rod 11 of the middle rod 1 is slidably sleeved with the lower nest 13. Multiple groups of umbrella rib assemblies 2 are pivotally connected to the upper nest 12 and the lower nest 13 along the circumference of the upper nest 11 and the circumference of the lower nest 13 . The polygonal upper umbrella cloth 41 is tied to the center position of the outer sides of each group of umbrella rib assemblies 2 . The annular lower umbrella cloth 42 is tied to the outer periphery of each group of umbrella rib assemblies 2 . A control valve positioned between the upper umbrella cloth 41 and the total surface of the umbrella ribs is set at each group of umbrella rib assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com