Pre-bent aortic membrane-covered stent and manufacturing method thereof

A technology of covered stents and manufacturing methods, applied in stents, medical science, surgery, etc., can solve problems such as new aortic breaks, dissection/operation-related death, etc., to prevent new breaks, reduce and The effect of cracking and eliminating the elastic back force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

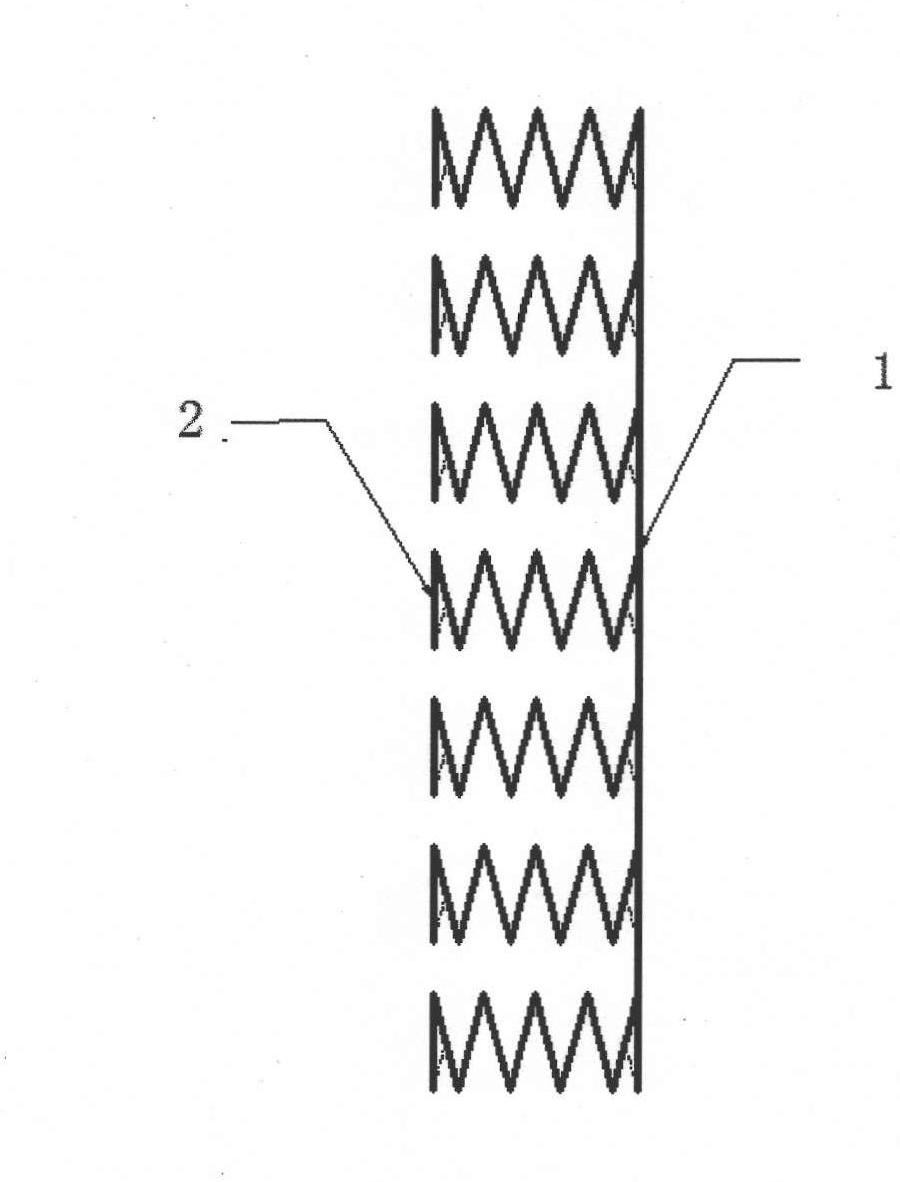

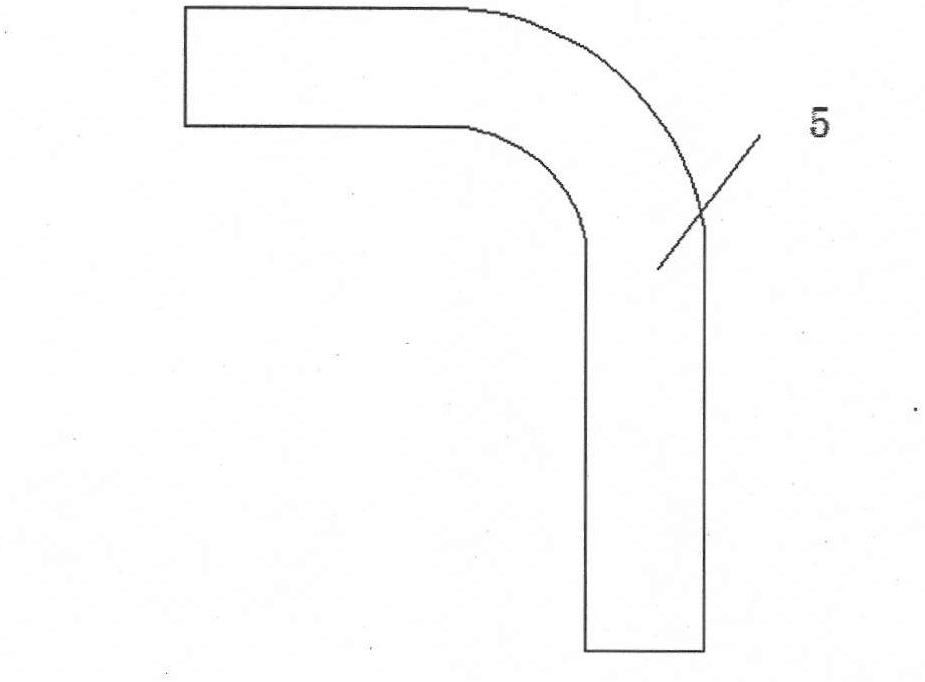

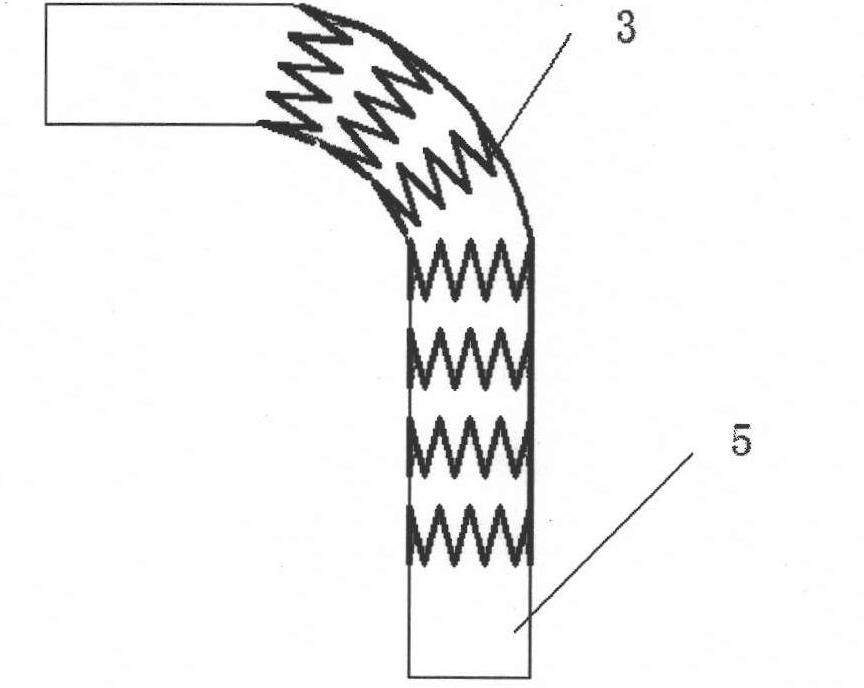

[0027] A pre-curved aortic stent graft consists of a metal stent 3 and a stent graft 4. The metal stent 3 includes a curved keel 1 and 7 rings of Z-shaped wave-shaped stents 2 connected to the keel 1. The metal bracket 3 is made of nickel-titanium alloy, and the covering film 4 is made of PET.

[0028] Its production method is:

[0029] 1. Preparation of Metal Scaffold 3:

[0030] Such as Image 6 As shown, it is a schematic diagram of forming a nickel-titanium alloy stent. The bending mold includes a straight tubular body 8, and 14 rows of stainless steel rods 9 (not all shown) are connected to the straight tubular body 8 for hanging nickel. Titanium alloy wires, two adjacent rows of stainless steel rods 9 are arranged in a staggered manner. Form a straight tubular stent as follows:

[0031] (1) Be that Ni content is 54.2wt%, Ti content is 45.3wt%, and the nickel-titanium alloy wire that diameter is 0.2mm starts from wherein a stainless steel bar 9 of the second row of be...

Embodiment 2

[0053] A pre-curved aortic stent graft consists of a metal stent 3 and a stent graft 4. The metal stent 3 includes a curved keel 1 and 7 rings of Z-shaped wave-shaped stents 2 connected to the keel 1. The metal bracket 3 is made of nickel-titanium alloy, and the covering film 4 is made of PET.

[0054] Its production method is:

[0055] 1. Preparation of Metal Scaffold 3:

[0056] Such as Image 6 As shown, it is a schematic diagram of forming a nickel-titanium alloy stent. The bending mold includes a straight tubular body 8, and 14 rows of stainless steel rods 9 (not all shown) are connected to the straight tubular body 8 for hanging nickel. Titanium alloy wires, two adjacent rows of stainless steel rods 9 are arranged in a staggered manner. Form the Z-shaped corrugated support 2 as follows:

[0057] (1) Be that Ni content is 57.1wt%, Ti content is 42.5wt%, and the nickel-titanium alloy wire that diameter is 0.4mm starts from wherein 1 stainless steel bar 9 of the second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com