Mixing extraction device with rotating barrel and extraction method

An extraction device and drum technology, applied in the field of liquid-liquid two-phase solvent extraction device, achieves the effect of small volume, good extraction effect, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

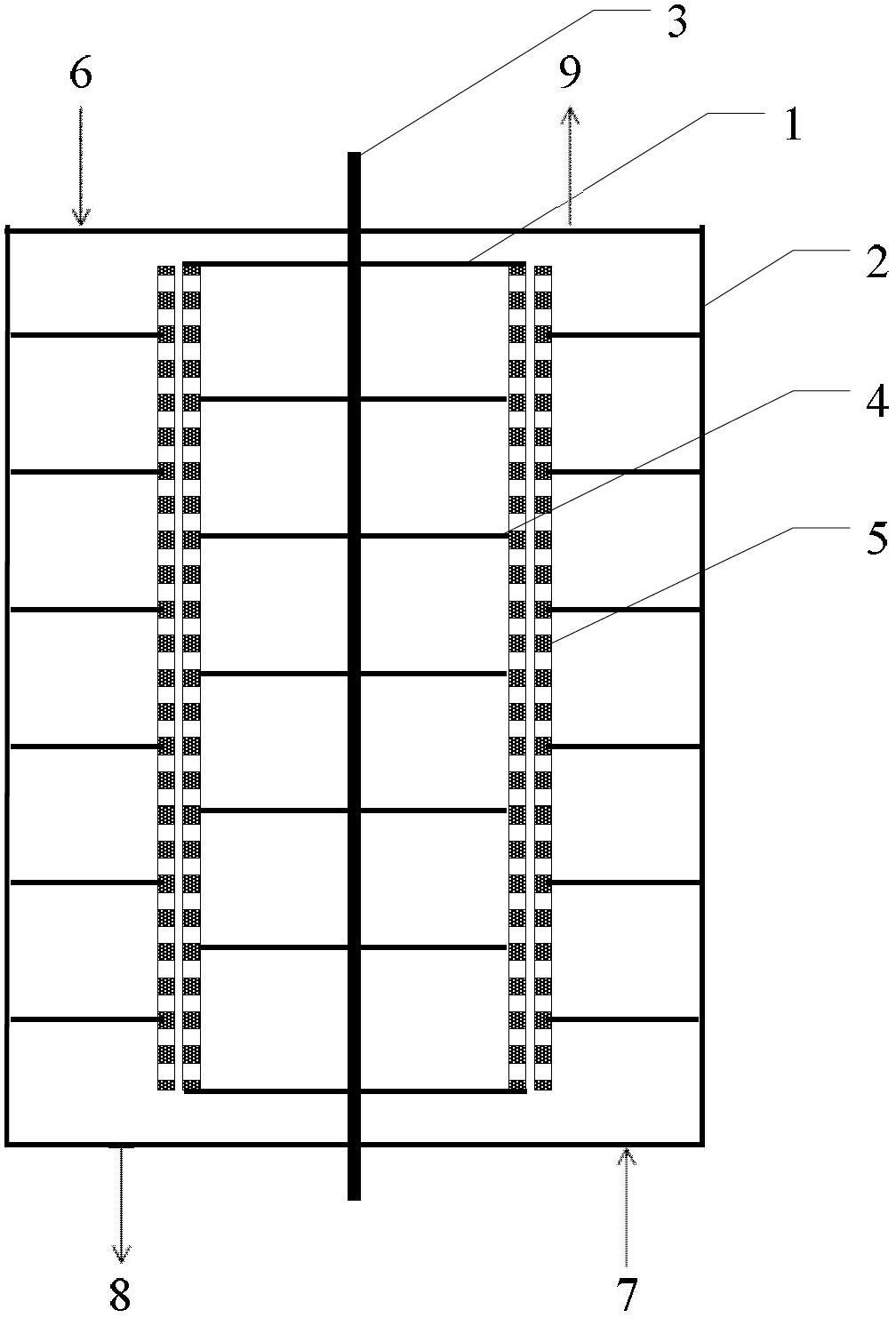

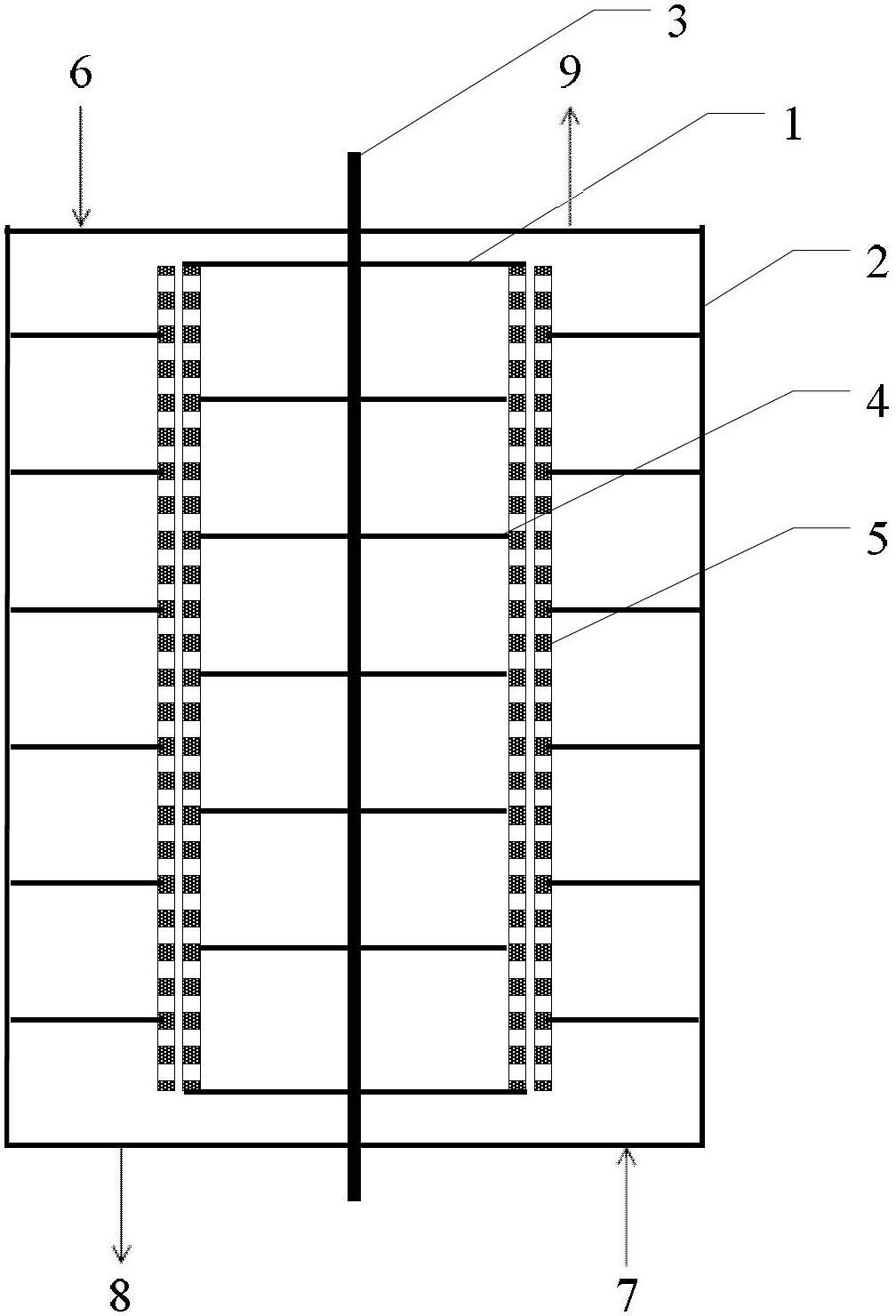

[0028] Such as figure 1 Shown is a drum mixing extraction device, which includes a fixed outer cylinder 2 and an inner cylinder 1; the inner cylinder 1 can rotate along a rotating shaft 3. When the equipment is running, the outer cylinder 2 is fixed, the inner cylinder 1 rotates along the direction of the rotating shaft 3, and the two move relatively. The device is provided with some small holes on the inner side of the outer cylinder and the outer side of the inner cylinder along the radial direction, and the small holes 4 on the inner cylinder wall and the small holes 5 on the outer cylinder wall are connected when they are opposite. The small holes 4 of the inner cylinder wall and the small holes 5 of the outer cylinder wall have the same size. The upper part of the outer cylinder is the heavy phase inlet 6 and the light phase outlet 9 , and the lower part is the light phase inlet 7 and the heavy phase outlet 8 . The device is made of fiberglass material.

Embodiment 2

[0030] A drum mixing extraction device, the device includes a base, a fixed outer cylinder 2 and an inner cylinder 1; the inner cylinder 1 can rotate along a rotating shaft 3, and the outer cylinder 2 and the rotating shaft 3 are fixed on the base. When the equipment is running, the outer cylinder 2 is fixed, the inner cylinder 1 rotates along the direction of the rotating shaft 3, and the two move relatively. A motor driving the rotating shaft 3 is installed in the base. The device is provided with some small holes on the inner side of the outer cylinder and the outer side of the inner cylinder along the radial direction, and the small holes 4 on the inner cylinder wall and the small holes 5 on the outer cylinder wall are connected when they are opposite. The small holes 4 of the inner cylinder wall and the small holes 5 of the outer cylinder wall have the same size. The upper part of the outer cylinder is the heavy phase inlet 6 and the light phase outlet 9 , and the lower ...

Embodiment 3

[0032] An extraction method of a drum mixing extraction device, firstly start the motor in the base to drive the rotating shaft 3 to rotate, and the inner cylinder 1 to rotate; the heavy phase enters from the heavy phase inlet 6, and the light phase enters from the light phase inlet 7; when the inner cylinder wall When the small hole 4 and the small hole 5 of the outer cylinder wall are facing each other, the heavy phase will drop and the light phase will rise, and both will be sheared and broken; when the holes are not opposite, the light and heavy phase cannot flow through the hole; The light phase droplets and the heavy phase droplets are completely mixed for extraction, and finally the light phase is collected from the light phase outlet 9, and the heavy phase is collected from the heavy phase outlet 8.

[0033] The device of the present invention and the applicant's prior application but unpublished CN 201210106978.7, an air-lift type air-stirred multi-layer circulation ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com