Patents

Literature

35results about How to "Meet industrial mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting pesticide from juglans mandshurica fruit green peels and leaves

InactiveCN102626113ARealize preparative extractionImprove product qualityBiocideAnimal repellantsJuglans mandshuricaPesticide product

Belonging to the technologies of pesticide preparation, the invention relates to a method for extracting a pesticide from juglans mandshurica fruit green peels and leaves. The method comprises: washing, air drying and crushing juglans mandshurica fruit green peels and leaves, sieving the crushed material through a sieve of 20 meshes, adding water into the sieved juglans mandshurica fruit green peel and leaf powder for immersion extraction or decoction extraction, then conducting solid-liquid separation, thus obtaining a juglans mandshurica fruit green peel and leaf pesticide. The method provided in the invention has the characteristics of simple extraction process, low production cost, high extraction efficiency, as well as good quality of the pesticide product, and can meet the use of industrial batch production.

Owner:王福

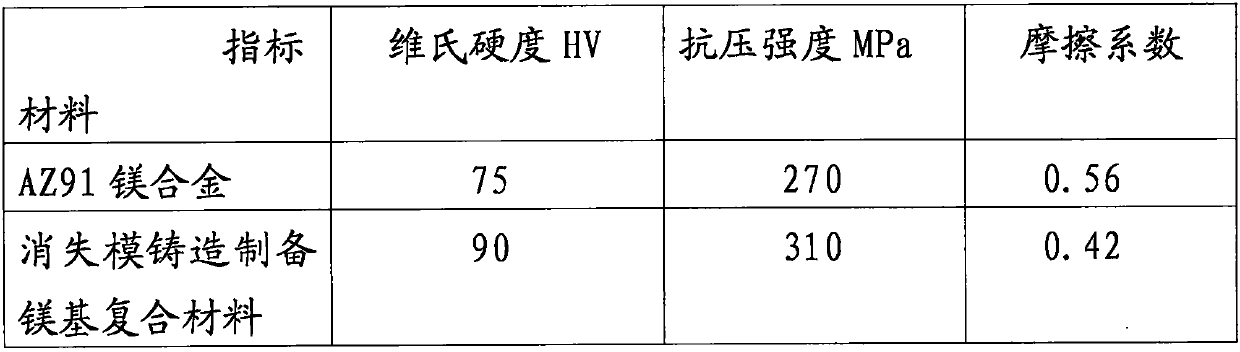

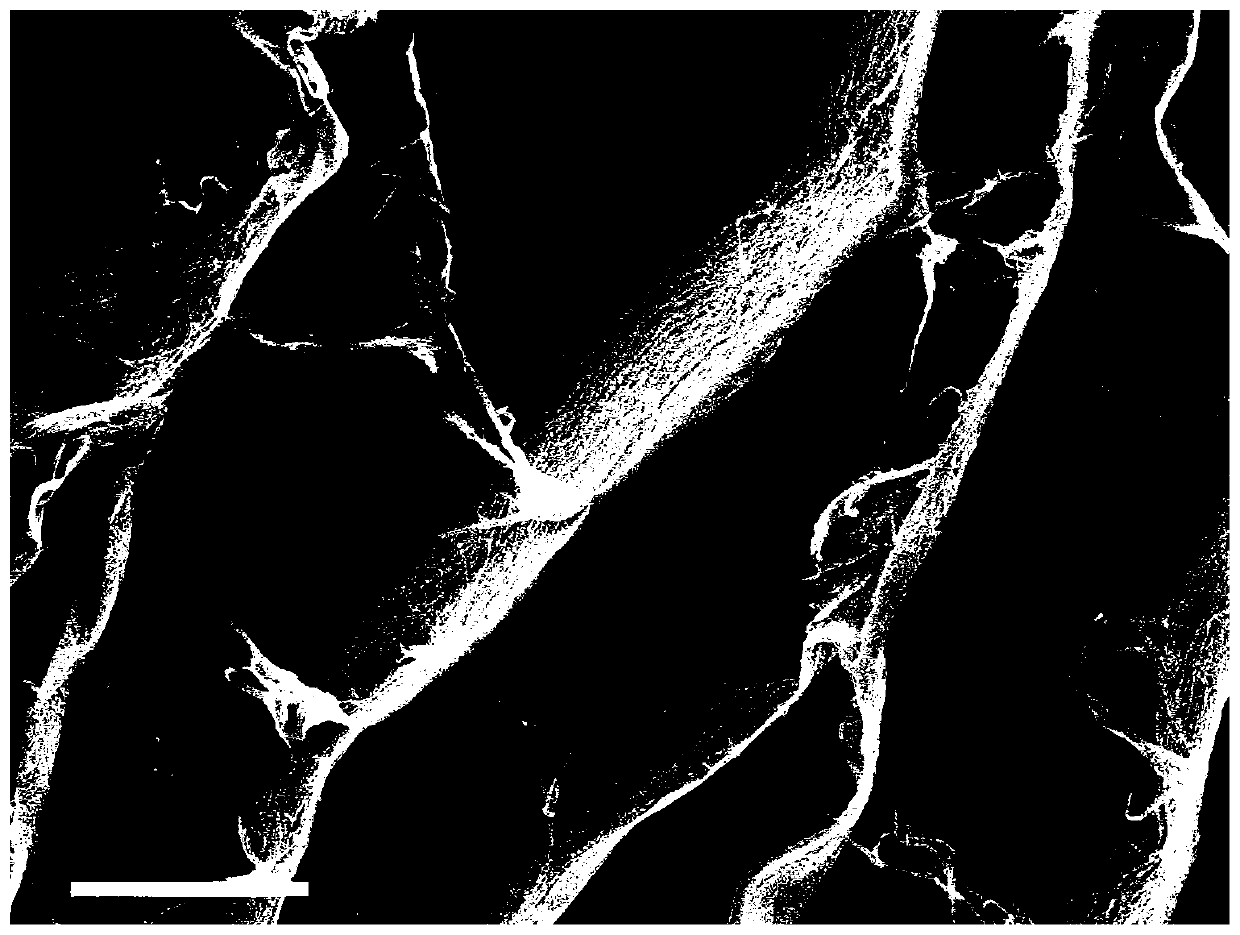

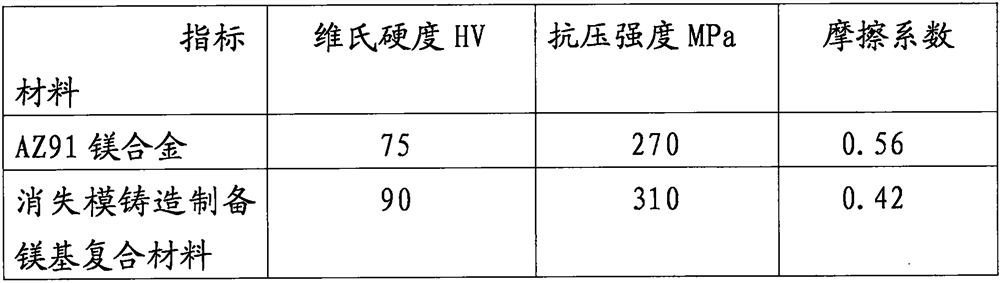

Method for preparing magnesium-based composite material by lost foam casting

ActiveCN110479959AGood dispersionEnhanced interface bindingFoundry mouldsFoundry coresMagnesium matrix compositeHardness

The invention discloses a method for preparing a magnesium-based composite material by lost foam casting, and belongs to the technical field of manufacturing of metal-based composite materials. According to the method, thigh-entropy alloy particles are prepared by pre-dispersing a mixture in magnesium alloy scraps, and the pre-dispersed mixture and magnesium alloy ingots are subjected to melt preparation and lost foam casting through mixing, melting, rotating and stirring, spinning spraying and vertical-direction mechanical vibration to obtain the magnesium-based composite material prepared bylost foam casting. The vickers hardness and compressive strength of the material are increased, the friction coefficient is reduced, and the method has the advantages that the method is scientific and reasonable and the material has good performance.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

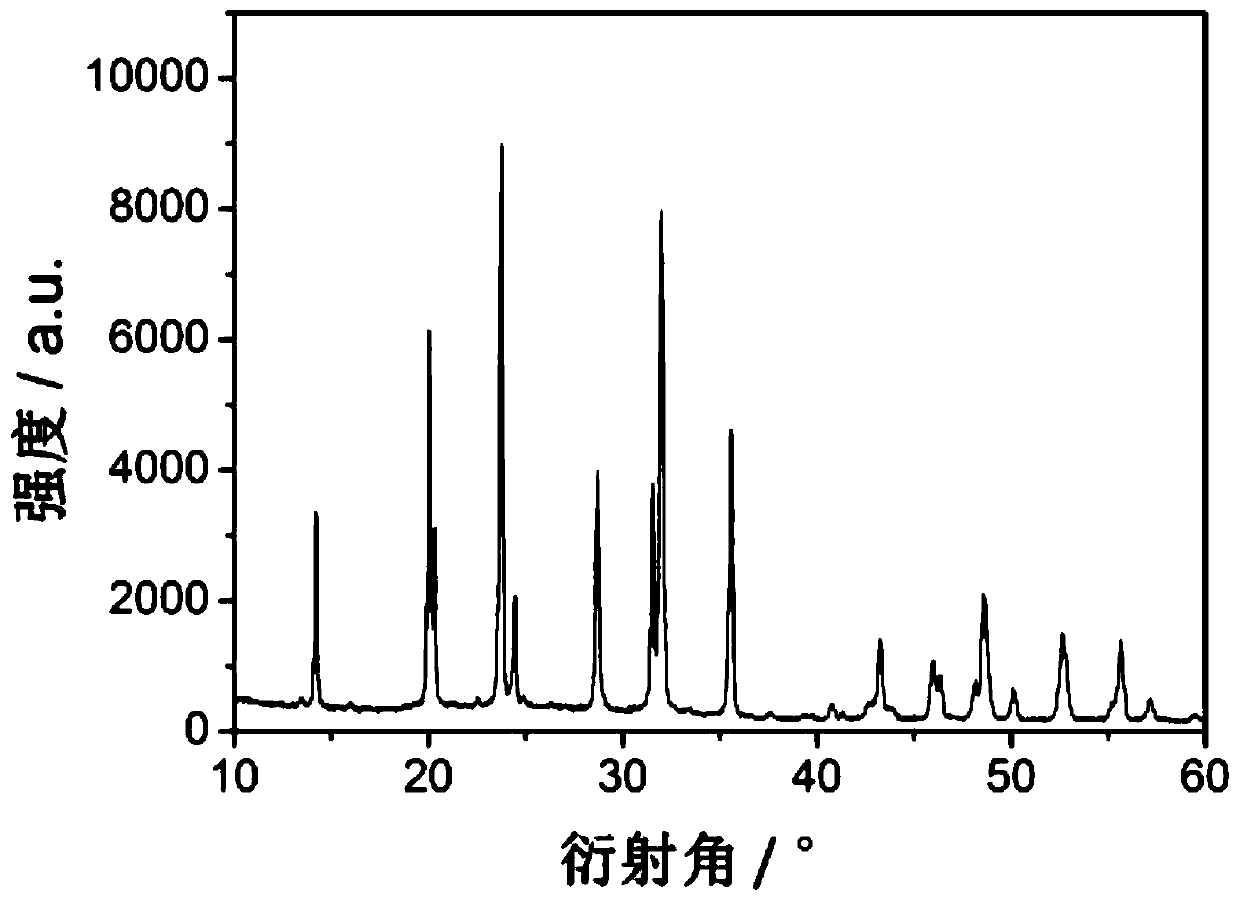

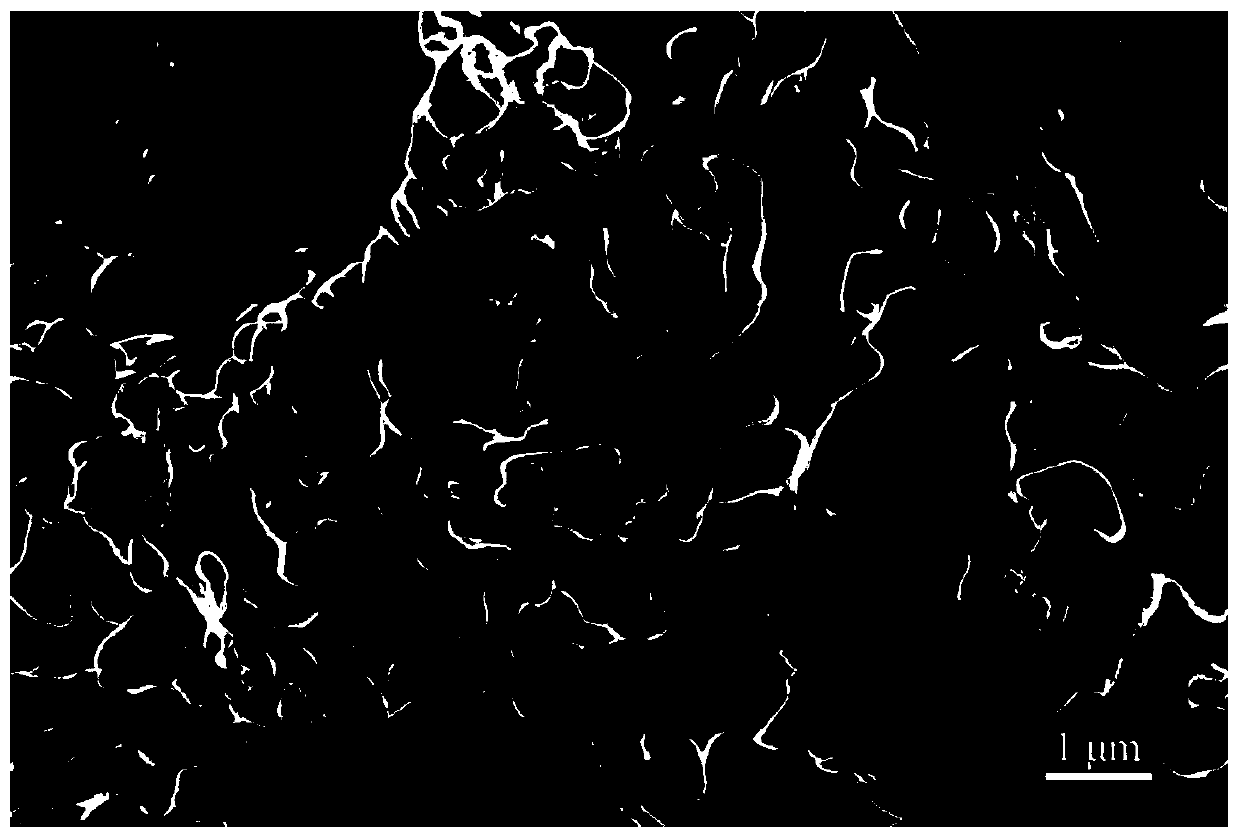

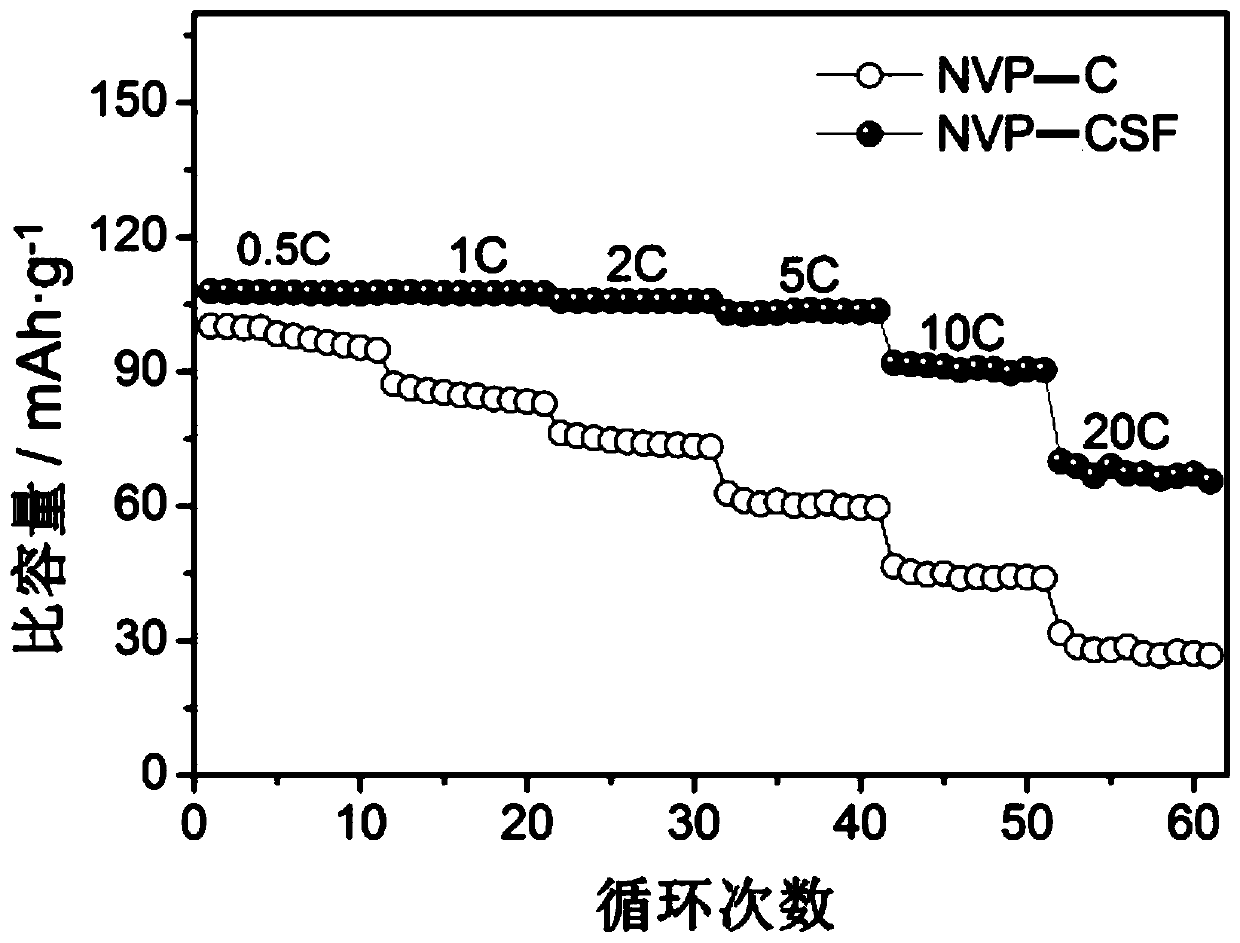

Preparation method of sodium vanadium phosphate sodium ion battery composite material

ActiveCN110165183AHigh reactivityImprove conductivitySecondary cellsPositive electrodesWater bathsSodium-ion battery

The invention relates to the technical field of sodium ion battery materials, and in particular to a preparation method of a sodium vanadium phosphate sodium ion battery composite material. The preparation method provided by the invention comprises the following steps of 1: mixing, ball milling and drying a sodium source, a vanadium source and a phosphorus source to obtain sodium vanadium phosphate precursor powders; 2: pre-sintering and sintering the sodium vanadium phosphate precursor powders is a non-oxidizing atmosphere to obtain sodium ion battery cathode material sodium vanadium phosphate; 3: dissolving a organic carbon source in a dispersant, adding the sodium vanadium phosphate and stirring the mixture in a water bath, evaporating the mixture until a gel is formed, and drying and milling the gel to obtain mixed powders; and 4, mixing and grinding a compound containing the Y element and the mixed powders obtained in the step 3, sintering the mixture at 300 to 500 degrees centigrade for 0.5 to 3 hours to obtain the sodium vanadium phosphate sodium ion battery composite material. The method can solve the technical problem that the existing sodium vanadium phosphate has low electronic conductivity and thus seriously limits its rate performance and cycle performance.

Owner:GUANGDONG POWER GRID CO LTD +1

Mixing extraction device with rotating barrel and extraction method

InactiveCN102671423ASimple and reasonable structureReduce volumeLiquid solutions solvent extractionPhase ratioEngineering

The invention relates to a mixing extraction device with a rotating barrel and an extraction method. The mixing extraction device comprises a fixed outer barrel and an inner barrel, the inner barrel can rotate along a rotating shaft, and slits between the outer barrel and the inner barrel are very small. When equipment runs, the outer barrel is fixed, the inner barrel rotates in the direction of the rotating shaft, and the inner barrel and the outer barrel can move relative to each other. When extraction is carried out, first a motor in a base is started to drive the rotating shaft to rotate, and the inner barrel rotates; heavy phase materials enter from a heavy phase inlet, and light phase materials enter from a light phase inlet; when small holes of an inner barrel wall are opposite to small holes of an outer barrel wall, the heavy phase materials descend, the light phase materials rise, and the heavy phase materials and the light phase materials are sheared and broken; when the small holes of the inner barrel wall are not opposite to the small holes of the outer barrel wall, the heavy phase materials and the light phase materials cannot flow through the holes; and after a period of time, the sheared light phase liquid drops and the sheared heavy phase liquid drops are totally mixed, and extraction is carried out. The extraction device is particularly suitable for an easily-emulsified system with phase ratio of a far cry, and uniform mixing can be achieved in a short time on the condition that two phase interfaces are clear so to as to finish extraction.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

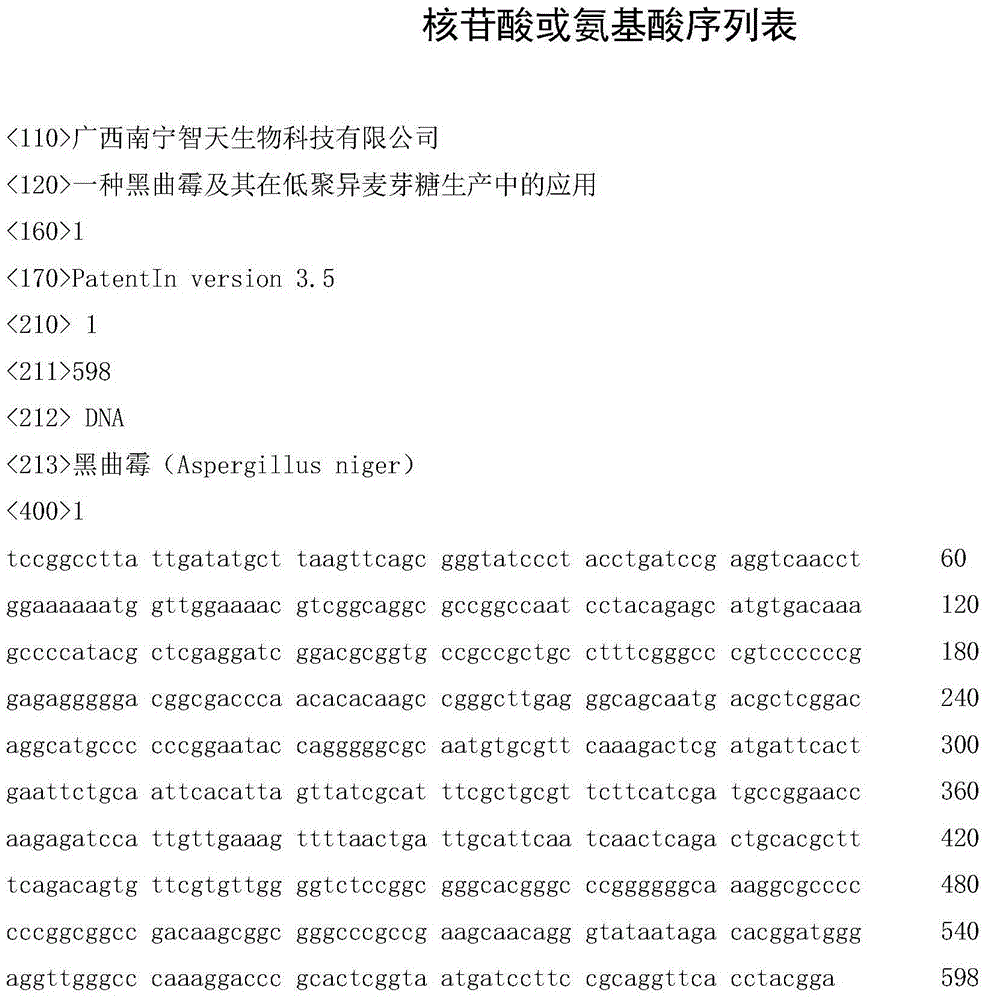

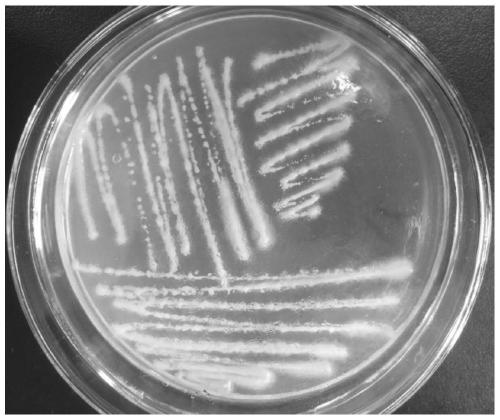

Aspergillus niger and application in production of isomaltose hypgather

ActiveCN104877911ASimple nutritional requirementsThe cultivation method is simpleFungiMicroorganism based processesAlgluceraseIsomaltooligosaccharide

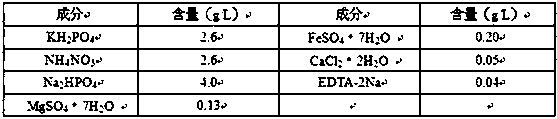

The invention discloses an aspergillus niger which is classified and named aspergillus niger M1 with the preservation number being CCTCC NO: M2014421. The preservation date is September 23nd, 2014, and the preservation department is China Center for Type Culture Collection. Alpha-glucosidase produced by the aspergillus niger M1 strain is endoenzyme, and the aspergillus niger M1 strain can produce isomaltose hypgather containing more than 65% of active trisaccharide (IG+P+IG3) under the condition of high temperature. The required reaction time of preparing IMO-500 type isomaltose hypgather containing 35% of active trisaccharide is only half of the reaction time of preparing the isomaltose hypgather containing more than 65% of active trisaccharide. The alpha-glucosidase produced by the strain has advantages of excellent temperature characteristic, short glucoside conversion time, high content of the active trisaccharide in the product and the like.

Owner:GUANGXI NANNING ZHITIAN BIOTECH

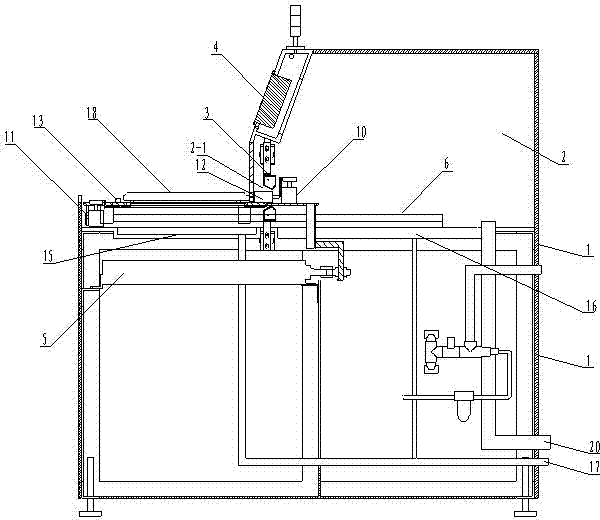

Air dryer of screen plate

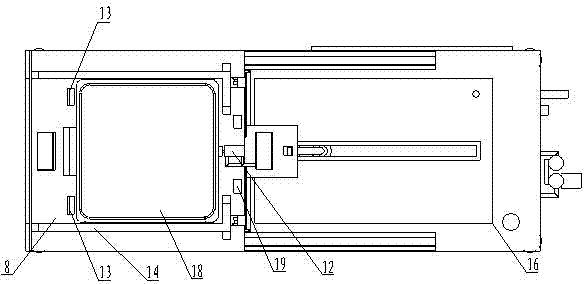

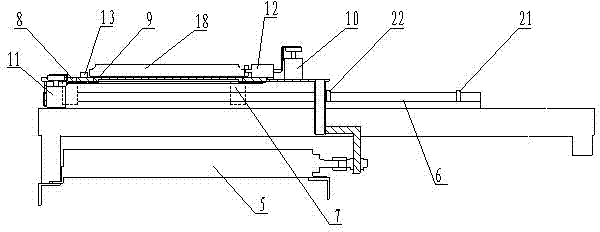

ActiveCN104329926ASafe and reliable dry processingEfficient and reliable drying processDrying gas arrangementsHigh volume manufacturingPulp and paper industry

The invention relates to the field of drying of solid materials or products without heating, and particularly relates to an air dryer used for drying a photovoltaic cell piece screen plate. In the current process of manufacturing the screen plate by solar cell manufacturing enterprises, the screen plate is commonly dried by a manual manner and the manual drying of the screen plate has the problems that the drying time is long, the efficiency is low, the drying effect is not ideal, the drying quality is not easy to control and the like, so that the requirements of industrial large-batch production cannot be met. The invention discloses an automatic screen plate air dryer; clean compressed air with adjustable temperature, humidity and air speed can be used for drying the screen plate; the drying efficiency is high and the drying effect is hood; in a drying process, the screen plate and a printing pattern thereof are not damaged and the requirements of the industrial large-batch production are met. The air dryer is simple and compact in design, easy to implement and lower in energy consumption cost; the air dryer is suitable for large-batch drying treatment on a plurality of solid parts and has a wide application and popularization prospect.

Owner:HEBEI JING LONG SUN EQUIP

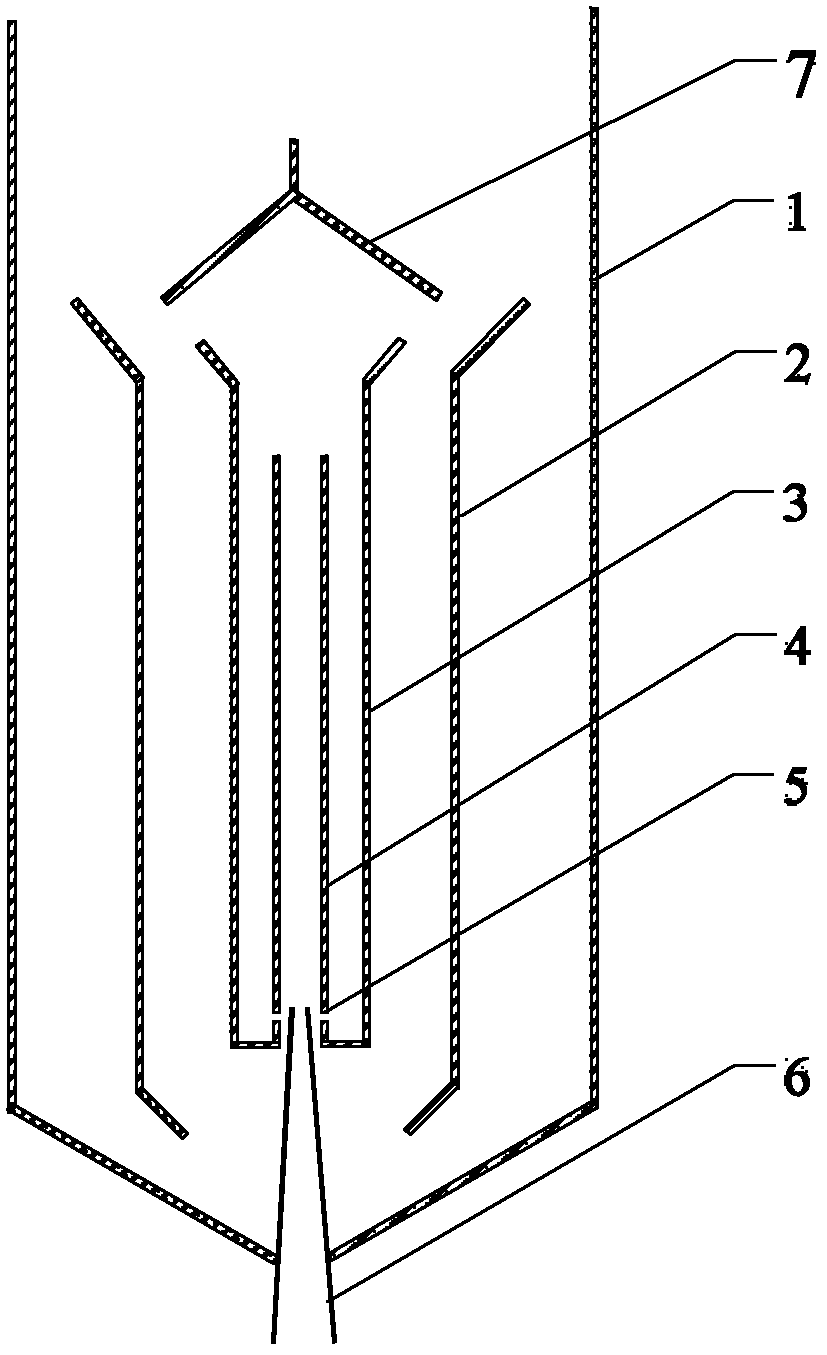

Airlift air stirring multi-sublayer circulating extraction device and method

InactiveCN102580350AReduce shear forceReduce RPM requirementsLiquid solutions solvent extractionPhase ratioOil water

The invention relates to an airlift air stirring multi-sublayer circulating extraction device and an airlift air stirring multi-sublayer circulating extraction method. The device comprises an outer pipe, an outer center pipe and an inner center pipe; and an inner pipe is arranged between the outer pipe and the outer center pipe. The method comprises the following steps: firstly, mixed solution to be extracted is added into the extraction device and then a light phase is added; after the filling of the air is started, air bubbles are generated in the inner center pipe, the small circulation of sucking down the light phase is carried out between the two center pipes and simultaneously the light phase is crushed; then the solution in the inner and the outer pipes starts to participate in circulation and the light phase is further crushed; and after a certain time, light phase drops are totally mixed with a mixed solution phase to form the stable multi-sublayer circulation. The airlift air stirring multi-sublayer circulating extraction device and the airlift air stirring multi-sublayer circulating extraction method are particularly suitable for the process of uniformly dispersing the light phase into a heavy phase in an intervallic phase ratio system which has an oil-water phase ratio of less than 1:1,000 and is easy to emulsify; the operation can be continuously carried out under the condition that the two-phase interface is clear; the emulsification phenomenon is avoided; the airlift air stirring multi-sublayer circulating extraction device and the airlift air stirring multi-sublayer circulating extraction method have low equipment investment, are easy to operate, have low power consumption and small shear force for the solution and are beneficial to keeping the activity of biomacromolecules.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

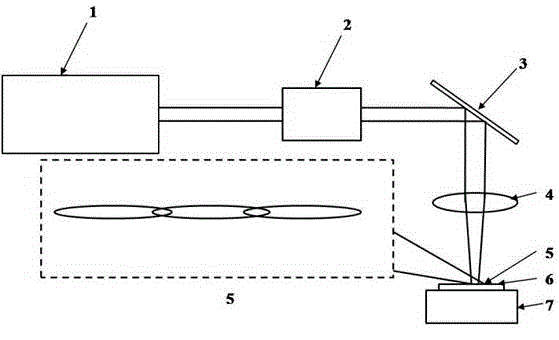

Laser doping technique used for improving adhesive force between metal electrode and crystalline silicon

InactiveCN102916077AImprove adhesionImprove performanceFinal product manufactureSemiconductor devicesLight spotMetal electrodes

The invention discloses a laser doping technique used for improving the adhesive force between a metal electrode and a crystalline silicon. The laser doping technique comprises wool making on a silicon wafer, boron diffusion, mark growing, laser doping and electroplating. In the laser doping technique, linear focus light spots with uniform energy distribution are adopted, and the control on the waveforms of pulses is combined, so that after the laser is doped, the texturing appearance of the surface of the silicon can be kept, the uniform doping concentration distribution can be formed, thereby effectively improving the adhesive force between the electroplated metal electrode and the crystalline silicon; in addition, according to the method, the performance and the stability of a battery can be improved, and the battery conversion efficiency is improved, so as to meet the industrial production in a large scale.

Owner:ALTUSVIA ENERGY TAICANG

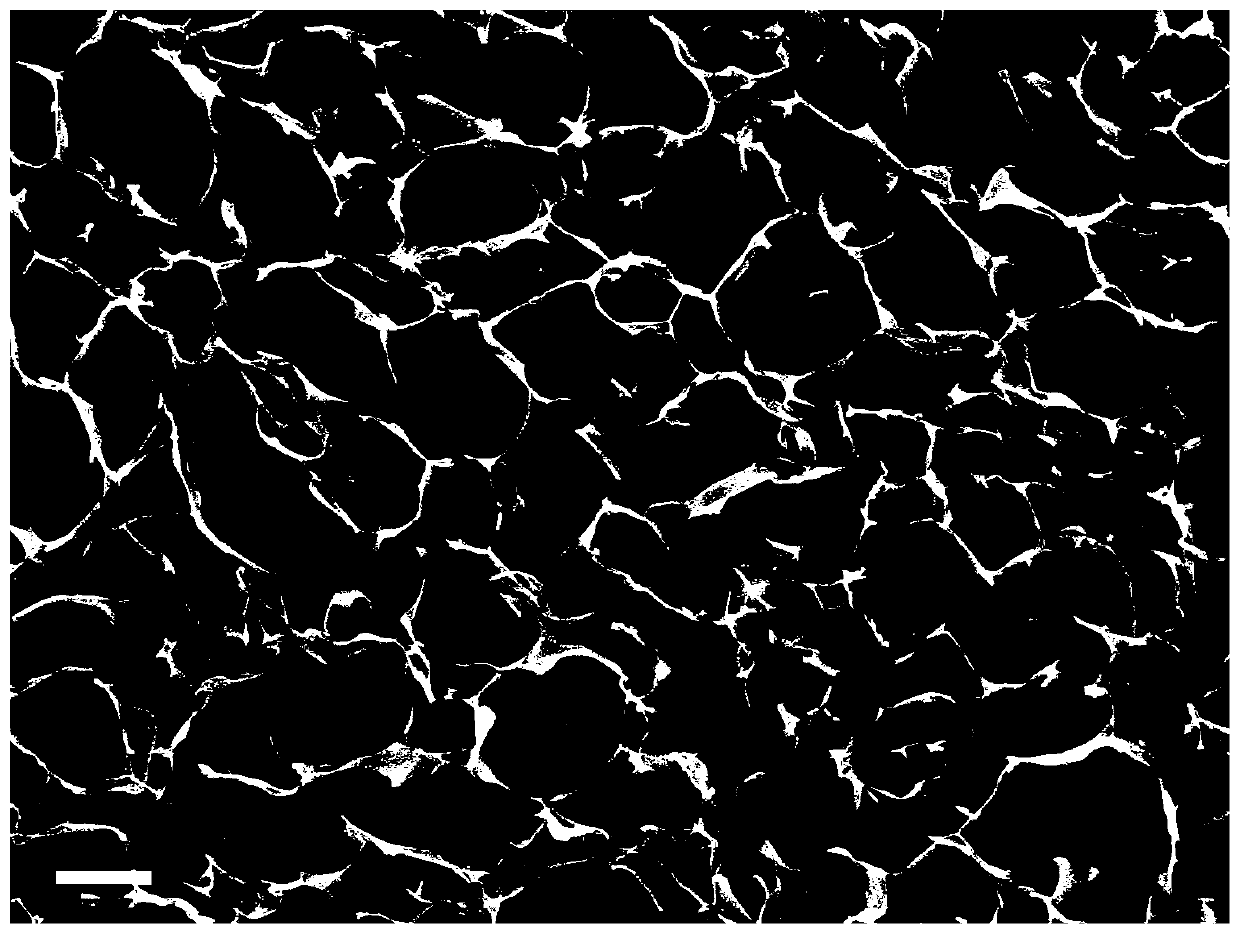

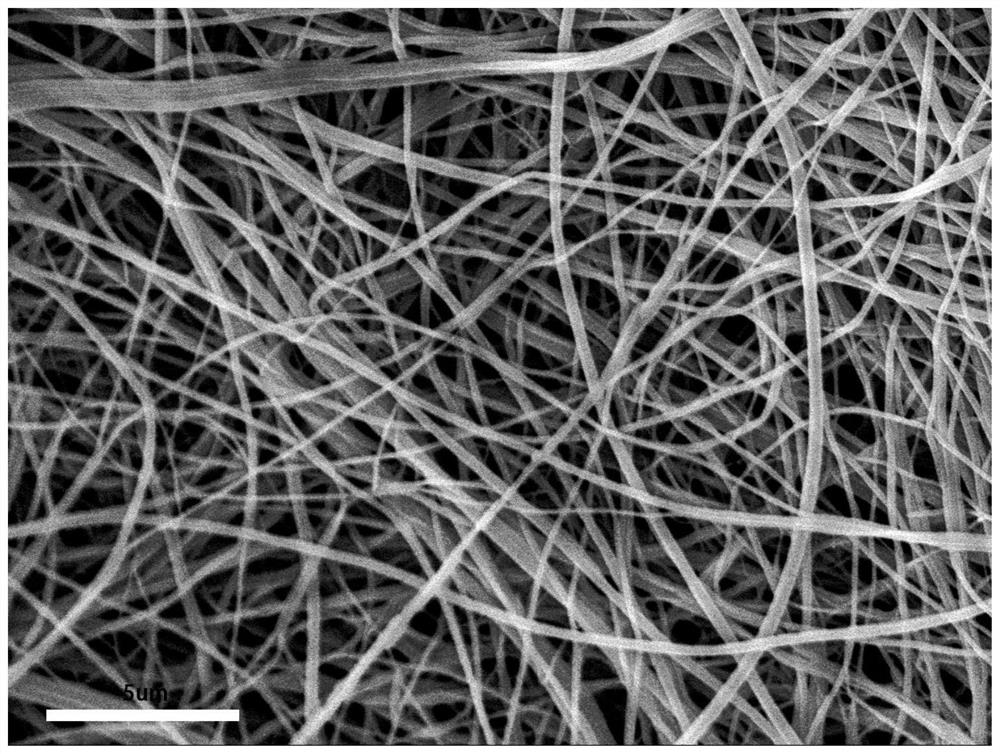

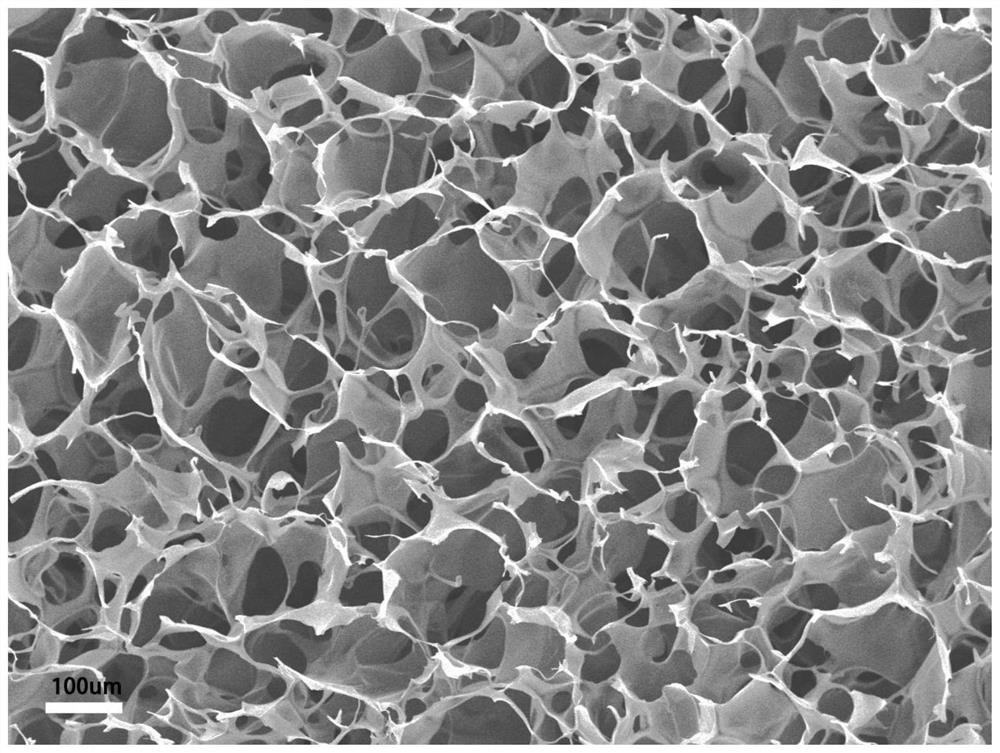

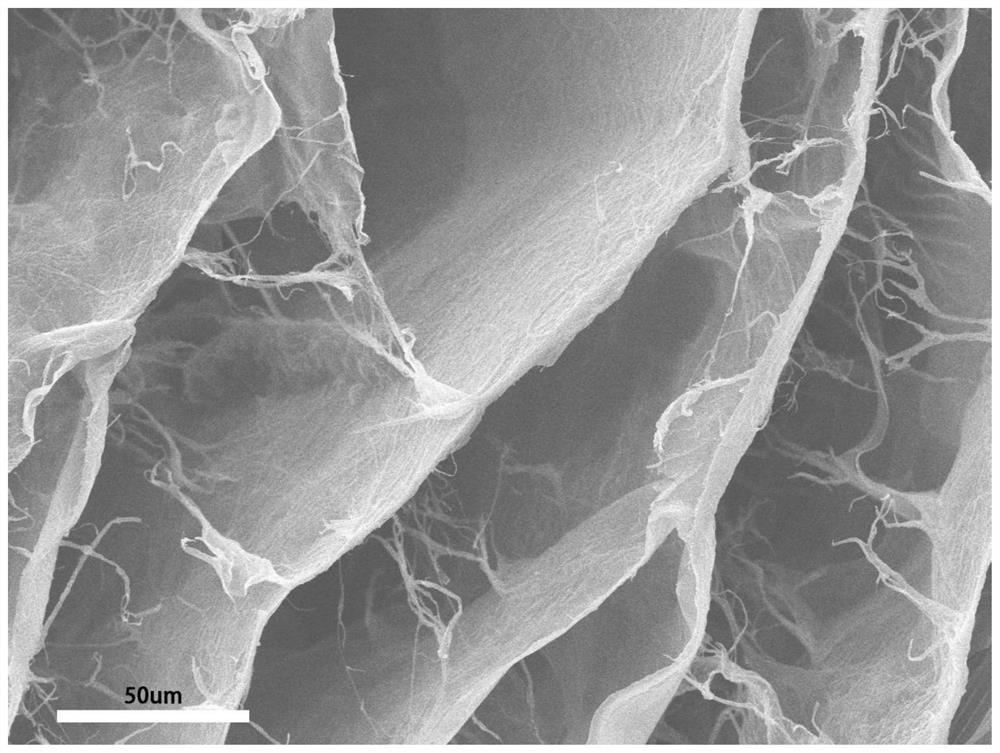

Nanofiber chitosan porous material and preparation method thereof

The invention discloses a nanofiber chitosan porous material and a preparation method thereof. The preparation method comprises the following steps: respectively preparing a chitosan solution and a polyvinyl alcohol-ethylene copolymer nanofiber suspension, uniformly mixing the chitosan solution and the polyvinyl alcohol-ethylene copolymer nanofiber suspension in proportion and freeze-drying to obtain the nanofiber chitosan porous material. With application of the method, the polyvinyl alcohol-ethylene copolymer nanofibers can be uniformly dispersed on the surface of the inner wall of the chitosan body, the problems that the traditional chitosan porous material is low in strength, prone to dissolution loss, short in service life and the like are solved, and the prepared porous material hasthe appropriate hot water dissolution loss rate, swelling rate, moisture content and compression strength so as to meet the requirements of practical application. The preparation method of the nanofiber chitosan porous material is simple and easy to implement and can meet industrial large-scale production; and the performance of the prepared porous material can be regulated and controlled by adjusting the ratio of the nanofibers to the chitosan so as to adapt to different application scenes, and the application range is wide.

Owner:WUHAN TEXTILE UNIV

Dendritic tryptophan compound, preparation method thereof and application of dendritic tryptophan compound as virus invasion inhibitor

The invention discloses a dendritic tryptophan compound, a preparation method of the dendritic tryptophan compound and application of the dendritic tryptophan compound serving as a virus invasion inhibitor, and belongs to the technical field of dendritic polymer synthesis. According to the technical scheme, the preparation method comprises the following steps: adding a carboxyl-terminated polyamide-amine dendritic compound and alkyl esterified tryptophan into a hydrochloric acid and N, N-dimethylformamide solution, and reacting at 20-60 DEG C for 3-10 days to obtain a compound containing tryptophan groups at the tail end; and carrying out rotary evaporation drying, washing and drying on the compound containing the tryptophan group at the tail end, and carrying out high performance liquid chromatography purification on an obtained residue to obtain a preliminarily purified compound containing the tryptophan group at the tail end. The compound is applied to the aspect of virus invasion inhibitors, can solve the problems of the existing virus invasion inhibitors, and has the characteristics of simple preparation method, good antiviral effect and wide antiviral property.

Owner:WEIHAI CY DENDRIMER TECH

Preparation method of magnesium-based composite material applied to automobile differential support

ActiveCN111804886AReduce material densityFunction increaseCasting cleaning apparatusMagnesium matrix compositeHigh entropy alloys

The invention discloses a preparation method of a magnesium-based composite material applied to an automobile differential support, and relates to a preparation method of a composite material appliedto the automobile differential support. The method aims at solving the technical problem that an existing AZ91D magnesium alloy is not strong enough to replace an aluminum alloy for an automobile differential support. Through spinning spraying and bidirectional stirring, high-entropy alloy particles are added into an AZ91D magnesium alloy melt, the stirring time can be shortened, and the aggregation effect of broken particles is remarkable; X-direction and Y-direction mechanical vibration is conducted simultaneously, aggregation of the particles in a broken side wall area is facilitated, and thus the particles in the side wall area are stirred to the middle of the melt along with shearing to be sufficiently mixed with the melt; and a screen net is placed on the surface of molten metal in amaterial barrel to filter oxidized slag inclusions, and finally an extrusion casting process is conducted to prepare a product. The high-entropy alloy particles are uniformly dispersed, the strengthand hardness of the product are also greatly improved, the interior of the product is free of defects of oxidized slag inclusions, the particles are combined with a base body well, and the applicationsituation of the magnesium-based composite material can be further broadened.

Owner:哈尔滨吉星机械工程有限公司

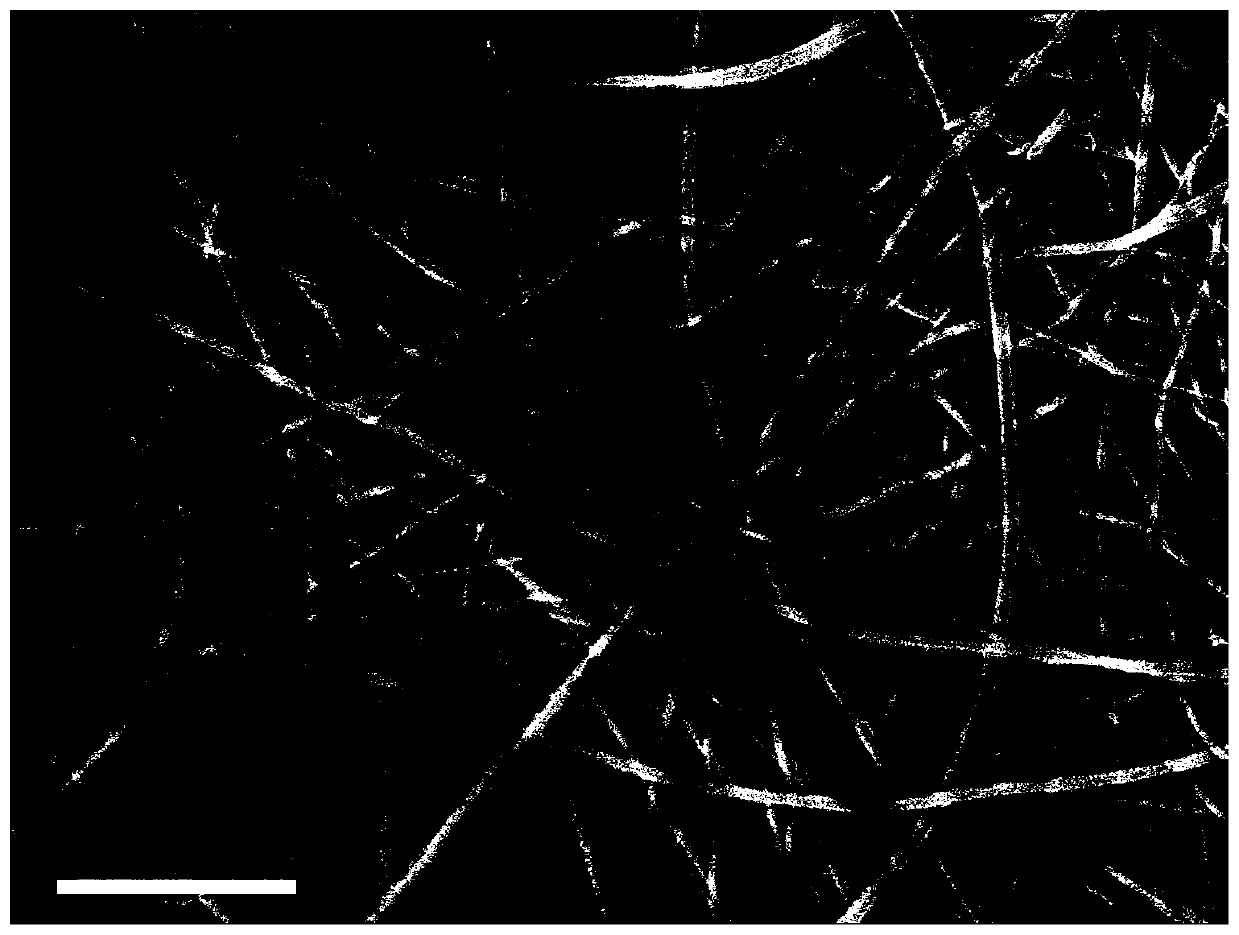

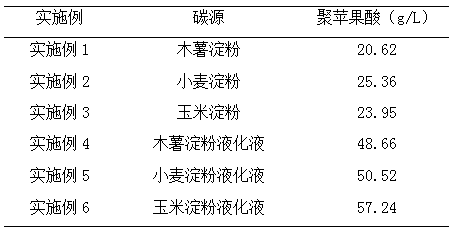

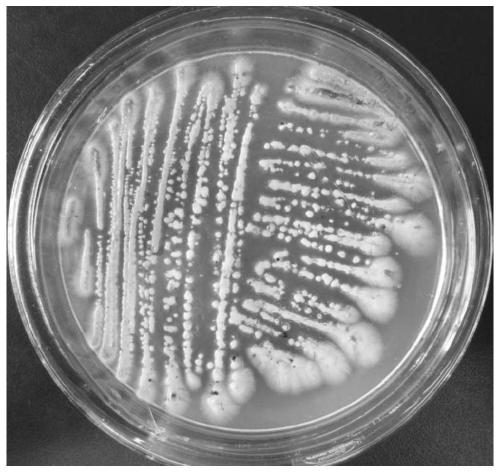

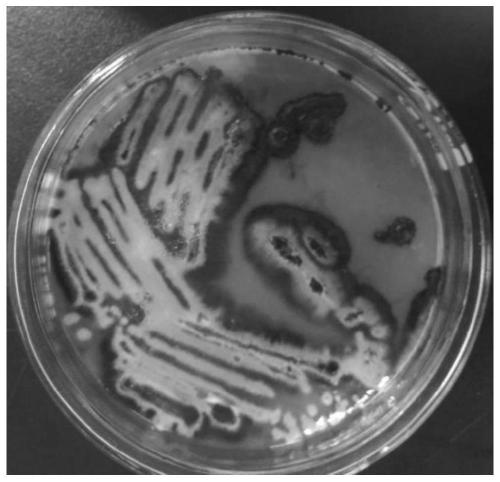

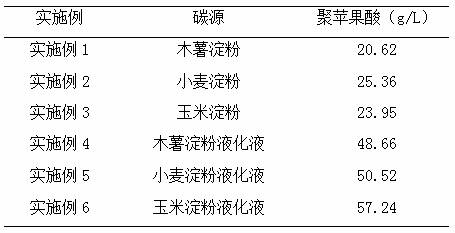

Aureobasidium pullulans strain capable of producing poly-beta-L-malic acid by utilizing starch and application thereof

The invention discloses an Aureobasidium pullulans strain capable of producing poly-beta-L-malic acid by utilizing starch and application thereof. The Aureobasidium pullulans strain is classified andnamed Aureobasidium pullulans GXL-1 under the preservation number of CCTCC NO: M 2018519 at China Center for Type Culture Collection (address: Wuhan University, Wuhan, China) since August 1, 2018. TheAureobasidium pullulans GXL-1 disclosed by the invention can directly use raw starch or a liquefied starch solution as a carbon source to produce poly-beta-L-malic acid at a mass concentration of 57g / L by carrying out batch fermentation at 30 DEG C without addition of a fermentation accelerator and growth factors; and moreover, no melanin is produced during the fermentation process. The Aureobasidium pullulans GXL-1 has the advantages of being low in fermentation cost, easy to realize product purification, and simple in process; and thus, the Aureobasidium pullulans GXL-1 has very great production potentials.

Owner:GUANGXI UNIV

Preparation method for lost foam casting of high-entropy alloy particle-reinforced magnesium-based composite material

PendingCN111719074AGood heredityReduce coarseningFoundry mouldsFoundry coresMagnesium matrix compositeHigh entropy alloys

The invention relates to a preparation method for a magnesium-based composite material, in particular to a preparation method for lost foam casting of a high-entropy alloy particle-reinforced magnesium-based composite material. The method aims to solve the technical problem that in the preparation process of an existing magnesium-based composite material, the addition proportion of magnesium alloywaste is small, and the strength is poor when a large amount of magnesium alloy waste is added. By adopting a lost foam casting method, utilizing two-way shear stirring, adding high-entropy alloy particles and performing ultrasonic treatment in the casting process, structure heredity is effectively improved, uneven dispersion of the particles at different positions of a magnesium alloy melt is avoided, structure coarsening is reduced, grain growth in the solidification process is inhibited, grains are refined, the utilization rate of magnesium alloy waste is increased, and the performance ofthe lost foam casting product is improved. In the method, the utilization rate of AZ91D waste is high, the maximum waste addition amount accounts for 34% of the total mass, raw materials are saved, and costs are reduced. The method is also suitable for continuous production operation and is an environment-friendly method.

Owner:哈尔滨吉星机械工程有限公司 +1

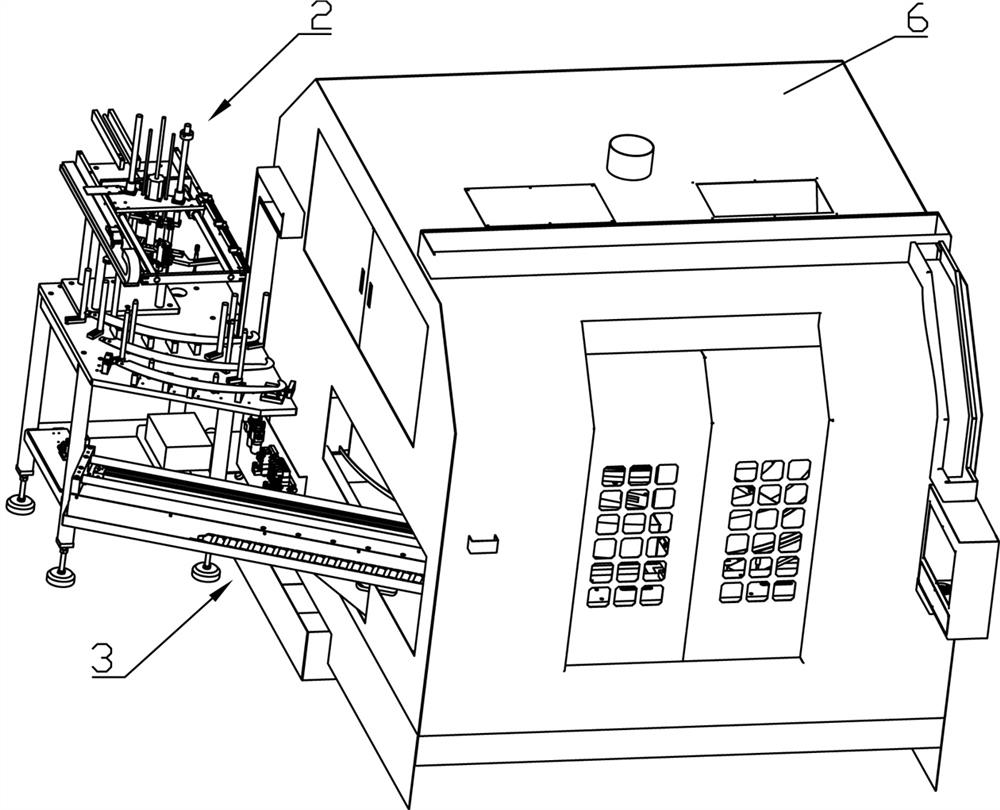

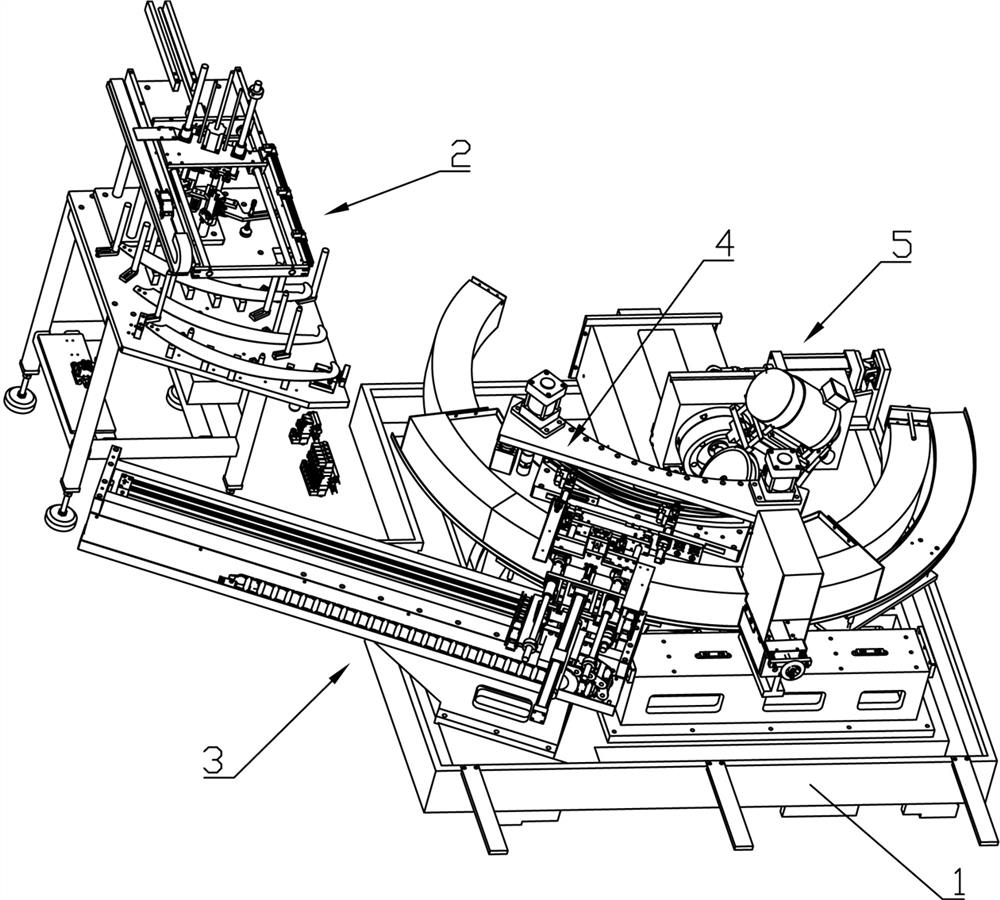

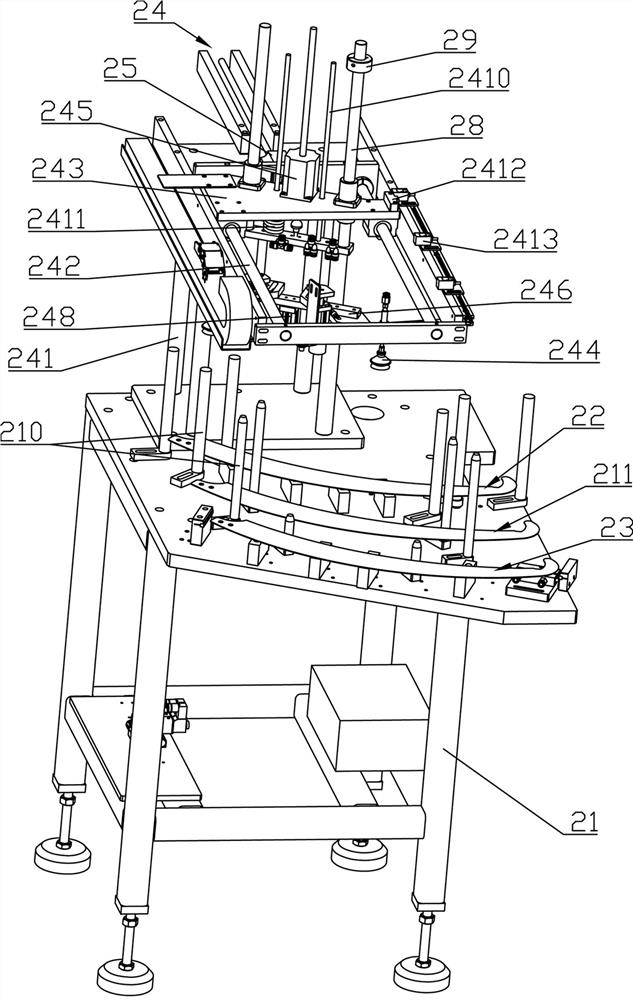

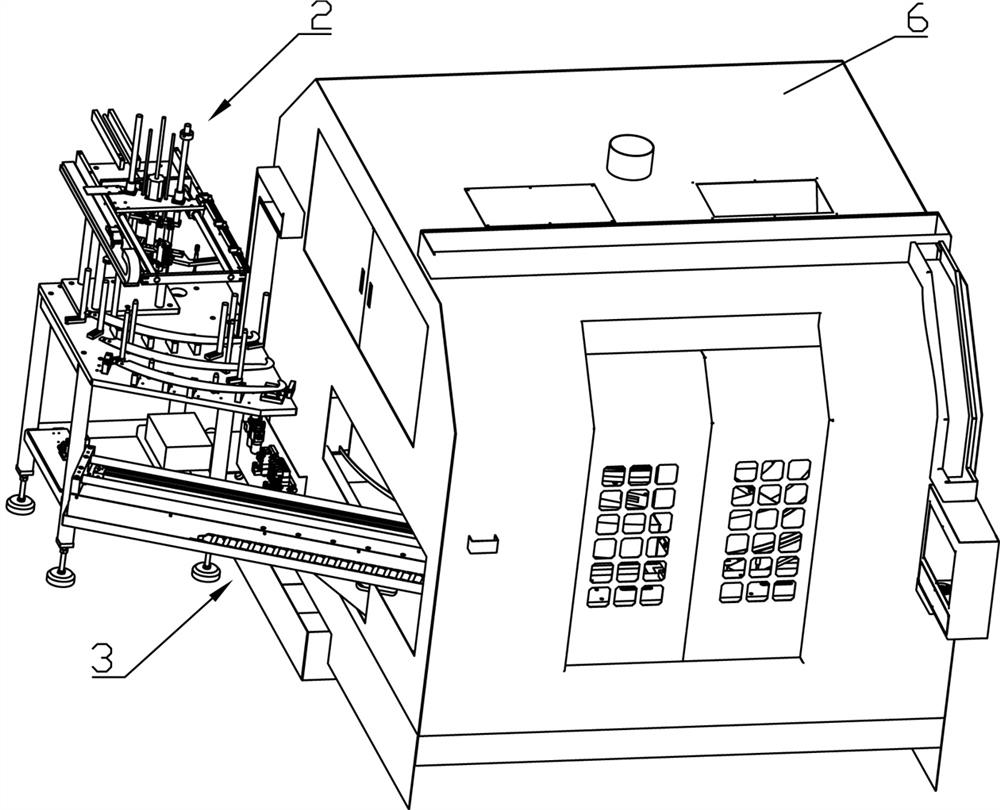

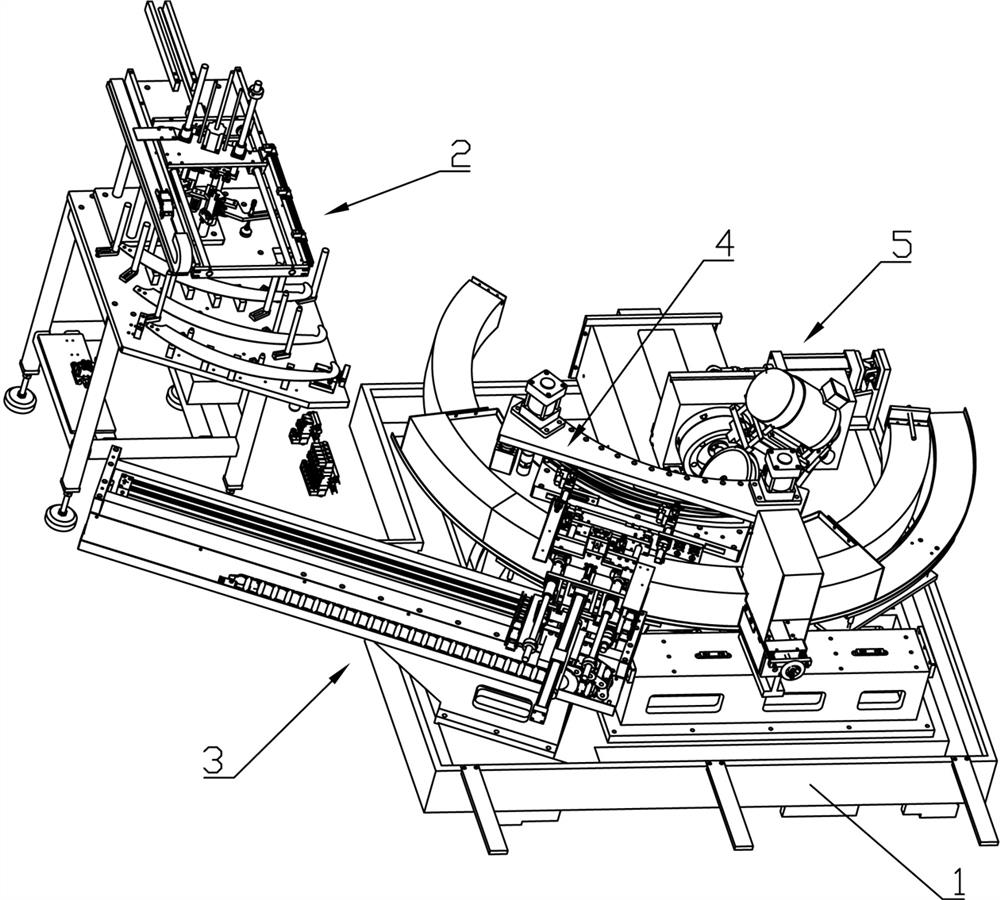

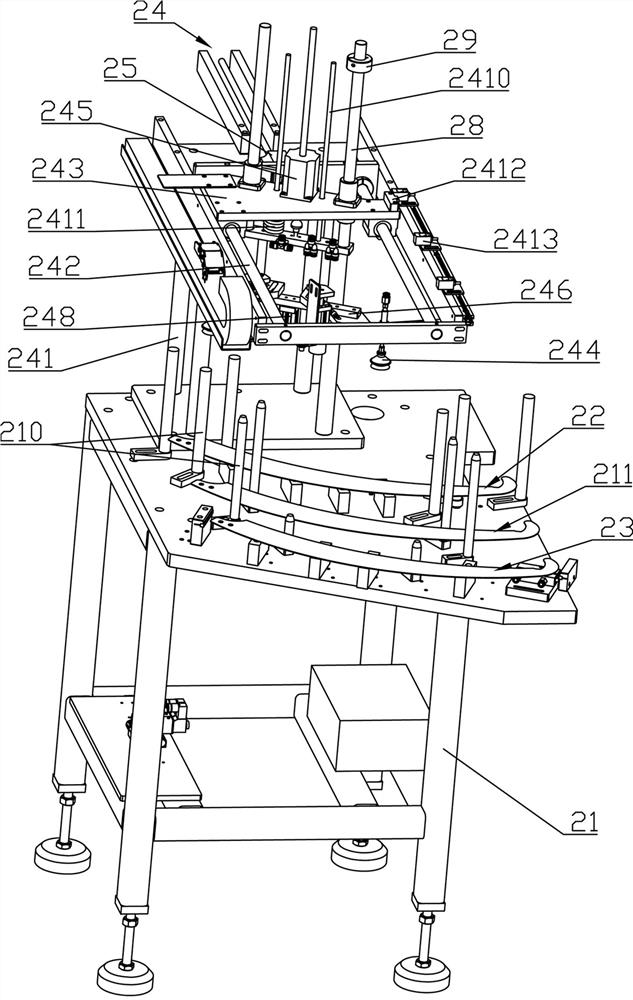

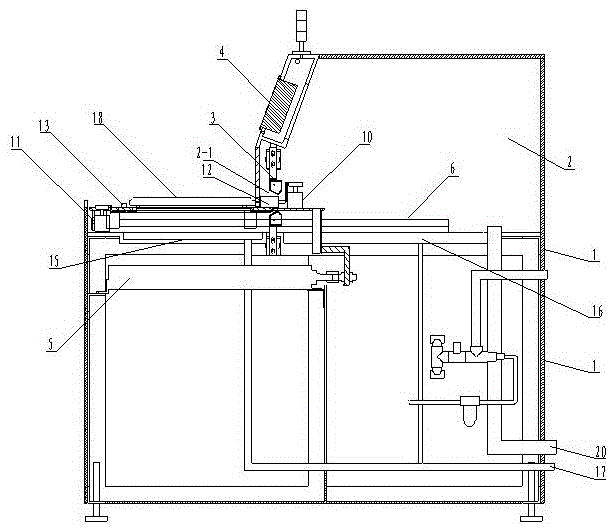

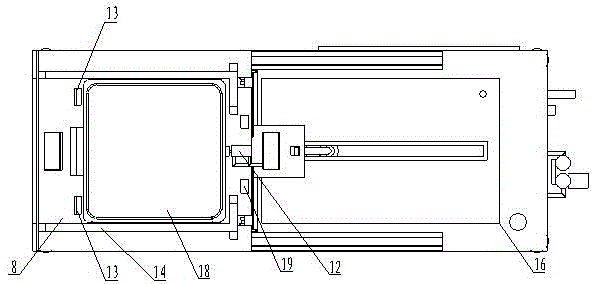

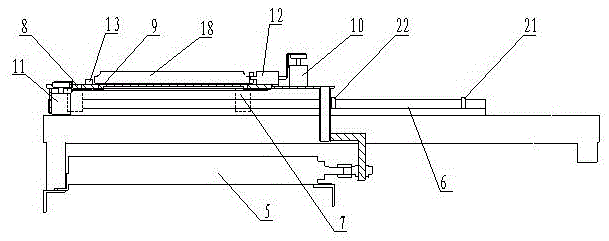

Automatic circular arc saw gear grinding machine

ActiveCN111922431ARealize automatic feeding processRealize automatic grindingMetal sawing tool makingGear grindingHigh volume manufacturing

The invention discloses an automatic circular arc saw gear grinding machine. The automatic circular arc saw gear grinding machine comprises a base, a material temporary storage mechanism, a material moving mechanism and a gear grinding mechanism. The base is provided with an arc-shaped track and a mounting base. The arc-shaped track is slidably provided with a working table. The working table is provided with a positioning device for positioning a workpiece. The arc-shaped track is further provided with a first arc-shaped rack. The mounting base is provided with a first driving motor. The material temporary storage mechanism comprises a first machine base and a sucker device for moving the workpiece from a first station to a second station. The material moving mechanism comprises a first manipulator. The first manipulator comprises a first driver, a first mounting plate and a first clamping device. After grasping the workpiece through the first clamping device, the material moving mechanism reciprocates between the second station and the positioning device. The gear grinding mechanism comprises a third machine base, a gear grinding machine head and a gear grinding wheel. The automatic circular arc saw gear grinding machine realizes the automatic processing of a circular arc saw, meets needs of industrial mass production, and has the advantages of high intelligence degree, production efficiency and precision, safety and reliability.

Owner:NINGBO CHEERY GARDEN TOOLS

A kind of preparation method of anisaldehyde

ActiveCN103497094BHigh content of purificationEasy to purifyCarbonyl compound preparation by oxidationEther preparation by isomerisationForeign matterIsomerization

The invention discloses a preparation method of anisic aldehyde and aims to provide a novel preparation method of anisic aldehyde in order to reduce the production cost of the anisic aldehyde and the environment pollution. The method comprises the following steps: isomerizing; carrying out refrigerated centrifugation; oxidizing; centrifuging; washing; and neutralizing. Estragole is subjected to steps such as isomerization, centrifugation and oxidization in the presence of a catalyst so that electrons in estragole molecules are rearranged, and foreign matters generate required anethole. The anethole is subjected to oxidization reaction under an acidic condition of manganese dioxide and transformed from ketone to aldehyde so that anisic aldehyde is obtained finally. According to the invention, the estragole is used as the raw material, the purification content of the estragole for preparing the anisic aldehyde can be up to over 97% and is about 13% higher than that of the traditional process. The preparation method is capable of remarkably increasing the yield of the anisic aldehyde and meeting the requirement for large-scale industrial production, easier to purify as well as little in equipment corrosion and environment pollution.

Owner:ZITONG HUIQUAN PERFUME CHEM

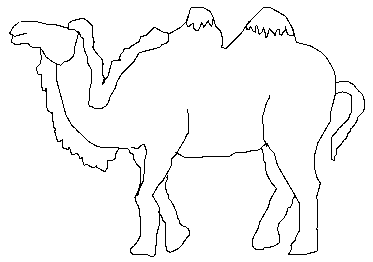

A method for making a hollow glazed camel

ActiveCN107512850BImprove fluencyImprove cooling effectSpecial ornamental structuresGlass blowing apparatusFritSolid structure

The invention discloses a manufacturing method of a hollow coloured glaze camel, belonging to the technical field of coloured glaze preparation. The hollow coloured glaze camel is prepared from transparent glass frit, ceramic white material and brown transparent glass frit. A manufacturing process mainly comprises the steps of preparing materials, nesting materials, manufacturing a hollow structure, manufacturing a solid structure, fine trimming and annealing; wherein in a hollow structure manufacturing process, shaping is carried out according to the order of rear legs, humps, front legs and neck, and the hump parts are manufactured by a manner of combination of blowing, pulling and internal ejecting, so that shape deformation caused by sticky wall appeared at bulging parts and the manufacturing is failed are prevented; the trunk, limbs and the hump parts of the camel are integrally formed to increase the fluency of the whole coloured glaze camel. The coloured glaze camel prepared by the manufacturing method provided by the invention is vivid in figure and color and high in yield, has simple method and is capable of meeting the industrial large-scale batch production; the ornamental value of animal-shaped coloured glaze products is improved.

Owner:淄博赛奥玻璃科技有限公司

An automatic circular arc saw tooth grinding machine

ActiveCN111922431BRealize automatic feeding processRealize automatic grindingMetal sawing tool makingGear grindingRobot hand

The invention discloses an automatic arc saw gear grinding machine, which comprises a base, a material temporary storage mechanism, a material shifting mechanism and a gear grinding mechanism. The base is provided with an arc-shaped track and a mounting seat, and a workbench is slid on the arc-shaped track. , the workbench is provided with a positioning device for positioning the workpiece, the arc track is also provided with a first arc rack, and the mounting seat is provided with a first drive motor; the material temporary storage mechanism includes a first base and a workpiece from the second A sucker device that moves from one station to a second station; the material transfer mechanism includes a first manipulator, and the first manipulator includes a first driver, a first mounting plate, and a first clamping device; the material transfer mechanism grasps through the first clamping device After the workpiece is taken, it goes back and forth between the second station and the positioning device; the gear grinding mechanism includes a third machine base, a gear grinding machine head and a gear grinding mechanism. The invention realizes the automatic processing of the circular arc saw, satisfies industrial mass production, and has the advantages of high intelligence, high production efficiency, high precision, safety and reliability.

Owner:NINGBO CHEERY GARDEN TOOLS

A high-yield polymalic acid Aureobasidium pullulans and its application

ActiveCN107674841BLow costThere is no problem of inhibitionFungiMicroorganism based processesBiotechnologyStarch corn

The invention belongs to the technical field of microorganism application, and in particular relates to Aureobasidium pullulans and its application in producing polymalic acid. A high-yield polymalic acid Aureobasidium pullulans, which is classified as Aureobasidium pullulans GXZ‑6, and the preservation number is CCTCC NO: M 2017517, and the preservation date is September 20, 2017. The preservation unit: China Center for Type Culture Collection, deposit address: Wuhan University, Wuhan, China. Aureobasidium pullulans (Aureobasidium pullulans) GXZ‑6 provided by the present invention can utilize tapioca starch, corn starch, wheat starch, soluble starch, starch saccharification liquid, maltose syrup as carbon source fermentation to produce polymalic acid, compared with utilizing glucose as For the production of polymalic acid by fermentation of carbon sources, the cost of raw materials is lower, and there is no problem that high-concentration carbon sources can inhibit the growth of bacteria.

Owner:GUANGXI UNIV

A kind of Aureobasidium pullulans using starch to produce polymalic acid and its application

The invention discloses a kind of Aureobasidium pullulans that utilizes starch to produce polymalic acid and its application. Aureobasidium pullulans ) GXL‑1, the deposit number is CCTCC NO: M 2018519, the deposit date is August 1, 2018, the deposit unit: China Center for Type Culture Collection, deposit address: China. Wuhan. Wuhan University. The Aureobasidium pullulans of the present invention ( Aureobasidium pullulans ) GXL‑1 can directly use raw starch or starch liquefaction liquid as the carbon source. Without adding fermentation promoters and growth factors, batch fermentation at 30°C can obtain up to 57g / L of polymalic acid, and no fermentation process occurs. The production of melanin has the advantages of low fermentation cost, easy product purification and simple process, and has great potential for industrial production.

Owner:GUANGXI UNIV

A method for preparing magnesium-based composite materials by lost foam casting

ActiveCN110479959BGood dispersionEnhanced interface bindingFoundry mouldsFoundry coresMagnesium matrix compositeHigh entropy alloys

The invention discloses a method for preparing a magnesium-based composite material by lost foam casting, and belongs to the technical field of manufacturing of metal-based composite materials. According to the method, thigh-entropy alloy particles are prepared by pre-dispersing a mixture in magnesium alloy scraps, and the pre-dispersed mixture and magnesium alloy ingots are subjected to melt preparation and lost foam casting through mixing, melting, rotating and stirring, spinning spraying and vertical-direction mechanical vibration to obtain the magnesium-based composite material prepared bylost foam casting. The vickers hardness and compressive strength of the material are increased, the friction coefficient is reduced, and the method has the advantages that the method is scientific and reasonable and the material has good performance.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Mixing extraction device with rotating barrel and extraction method

InactiveCN102671423BSimple and reasonable structureReduce volumeLiquid solutions solvent extractionPhase ratioEngineering

The invention relates to a mixing extraction device with a rotating barrel and an extraction method. The mixing extraction device comprises a fixed outer barrel and an inner barrel, the inner barrel can rotate along a rotating shaft, and slits between the outer barrel and the inner barrel are very small. When equipment runs, the outer barrel is fixed, the inner barrel rotates in the direction of the rotating shaft, and the inner barrel and the outer barrel can move relative to each other. When extraction is carried out, first a motor in a base is started to drive the rotating shaft to rotate, and the inner barrel rotates; heavy phase materials enter from a heavy phase inlet, and light phase materials enter from a light phase inlet; when small holes of an inner barrel wall are opposite to small holes of an outer barrel wall, the heavy phase materials descend, the light phase materials rise, and the heavy phase materials and the light phase materials are sheared and broken; when the small holes of the inner barrel wall are not opposite to the small holes of the outer barrel wall, the heavy phase materials and the light phase materials cannot flow through the holes; and after a period of time, the sheared light phase liquid drops and the sheared heavy phase liquid drops are totally mixed, and extraction is carried out. The extraction device is particularly suitable for an easily-emulsified system with phase ratio of a far cry, and uniform mixing can be achieved in a short time on the condition that two phase interfaces are clear so to as to finish extraction.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

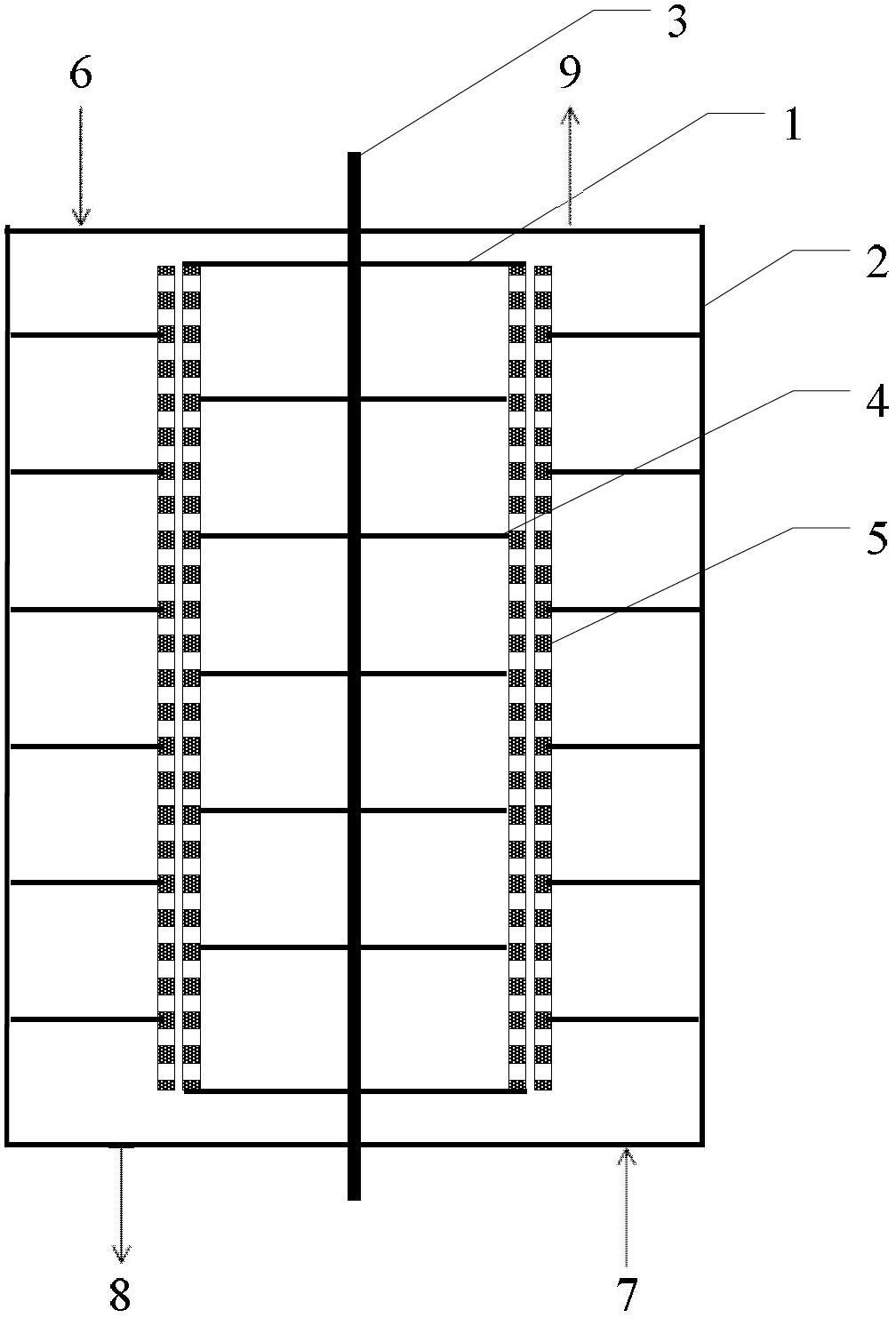

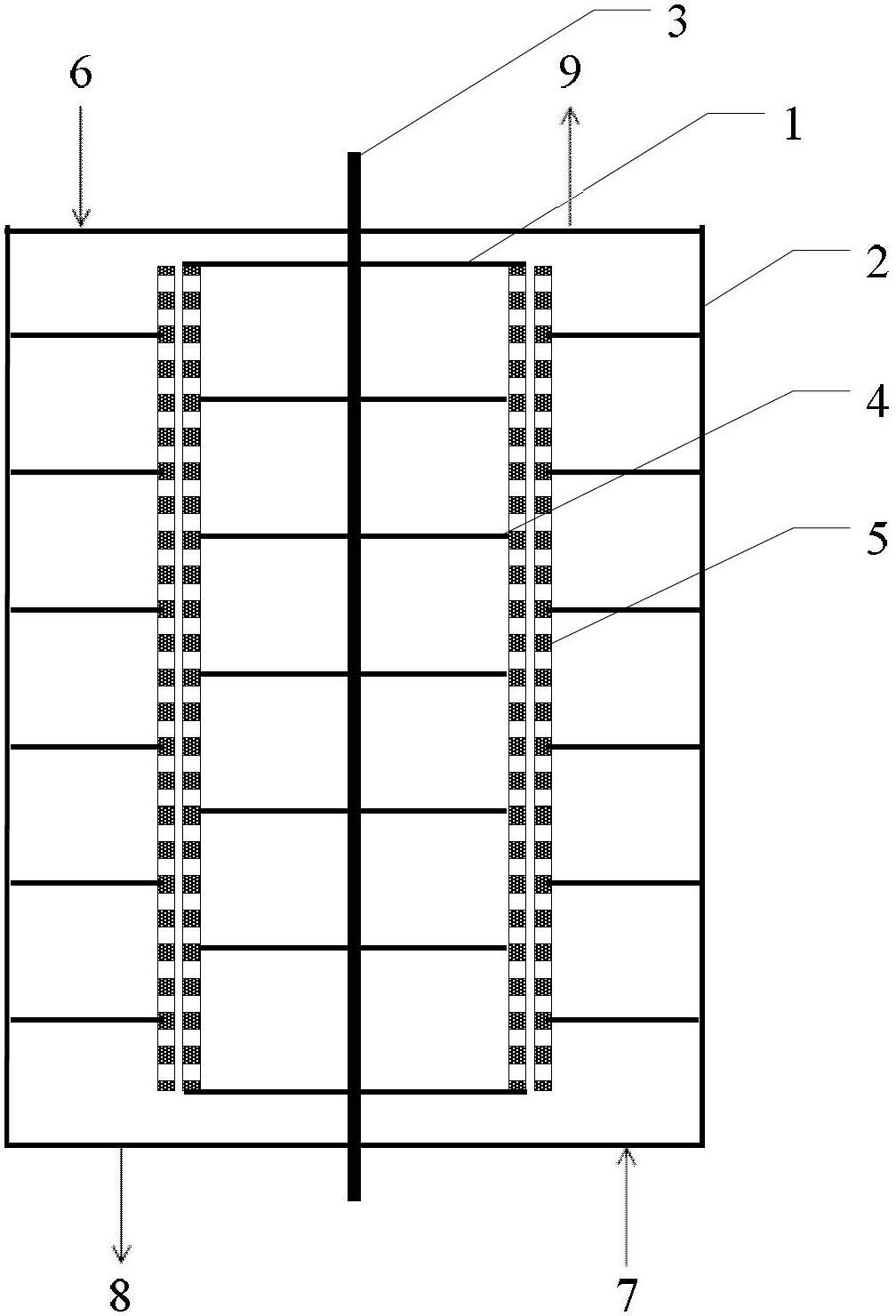

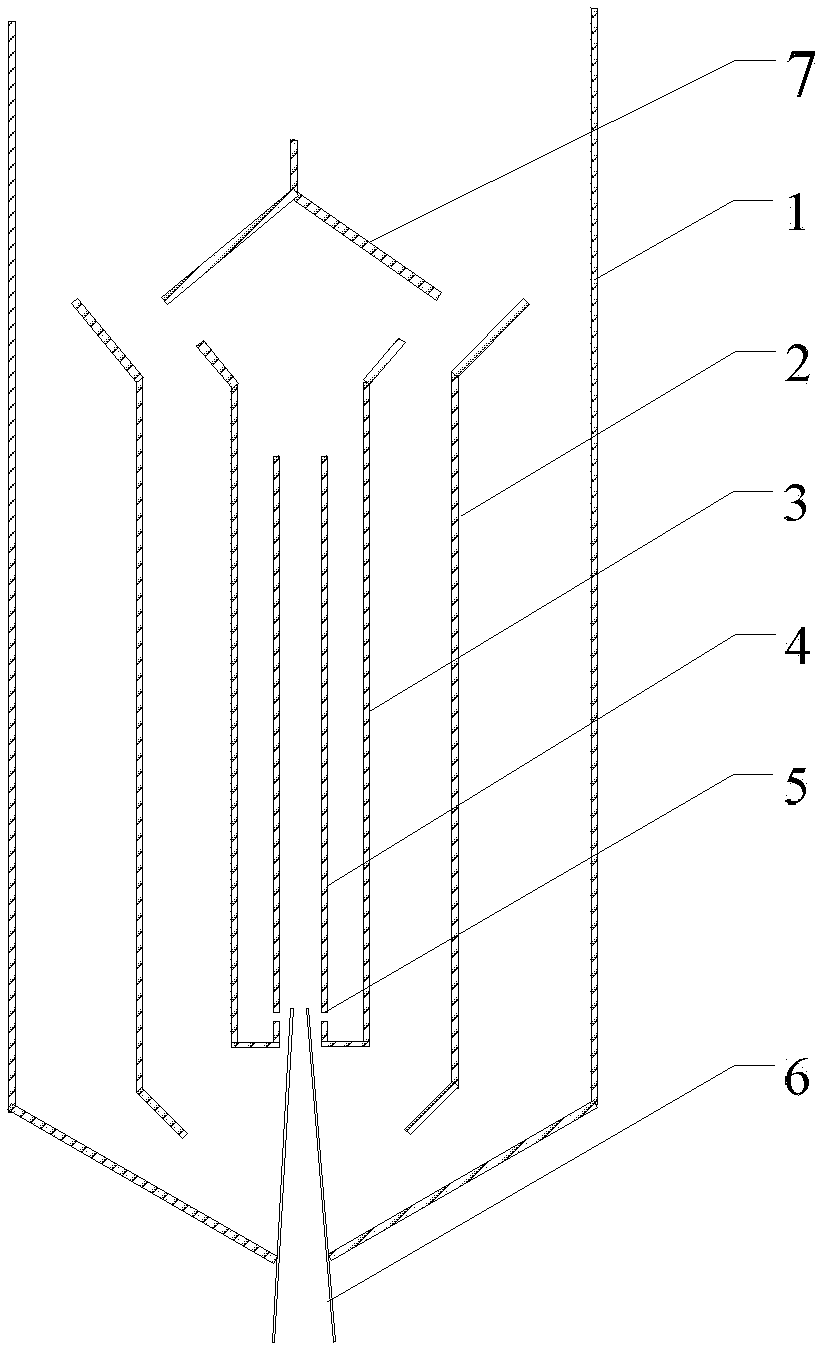

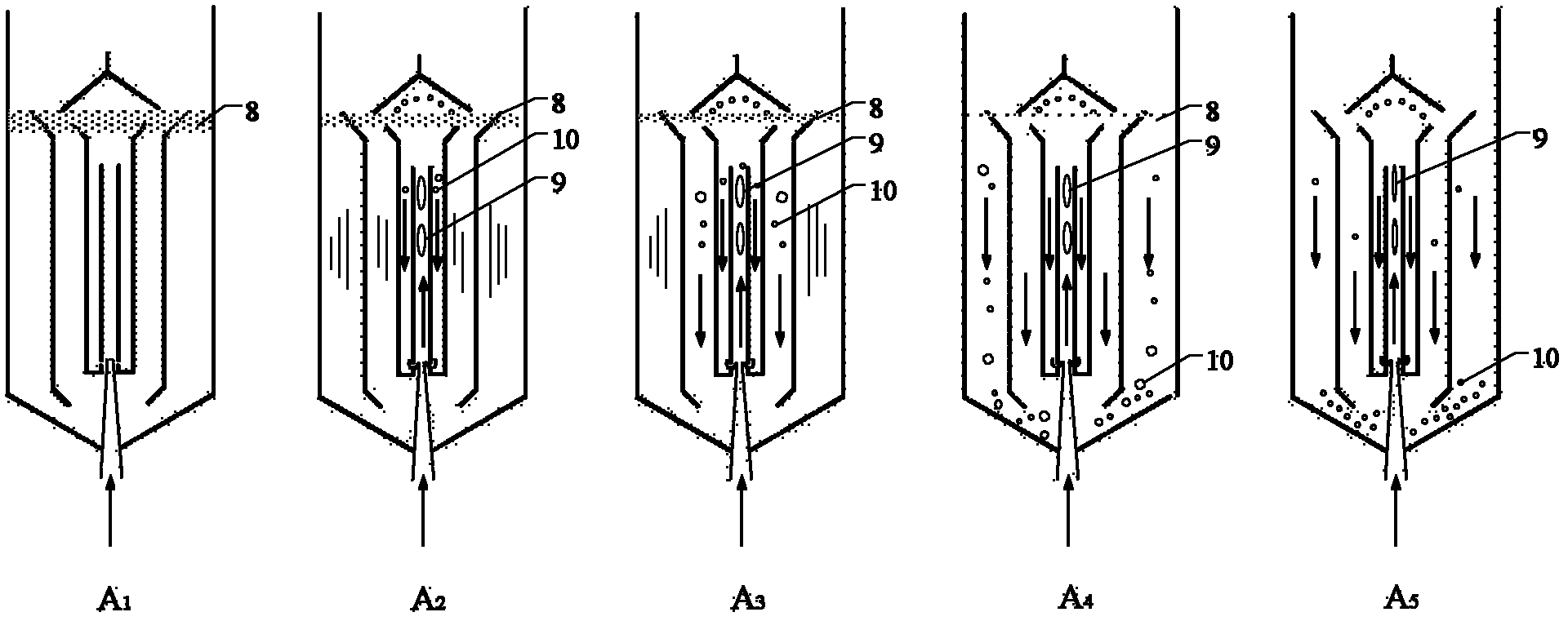

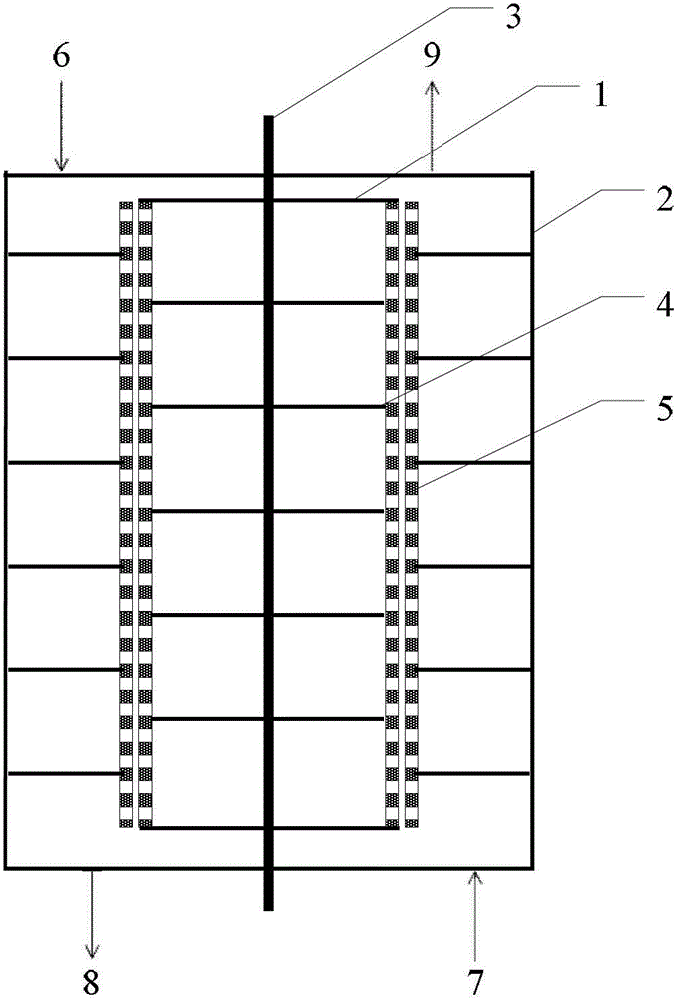

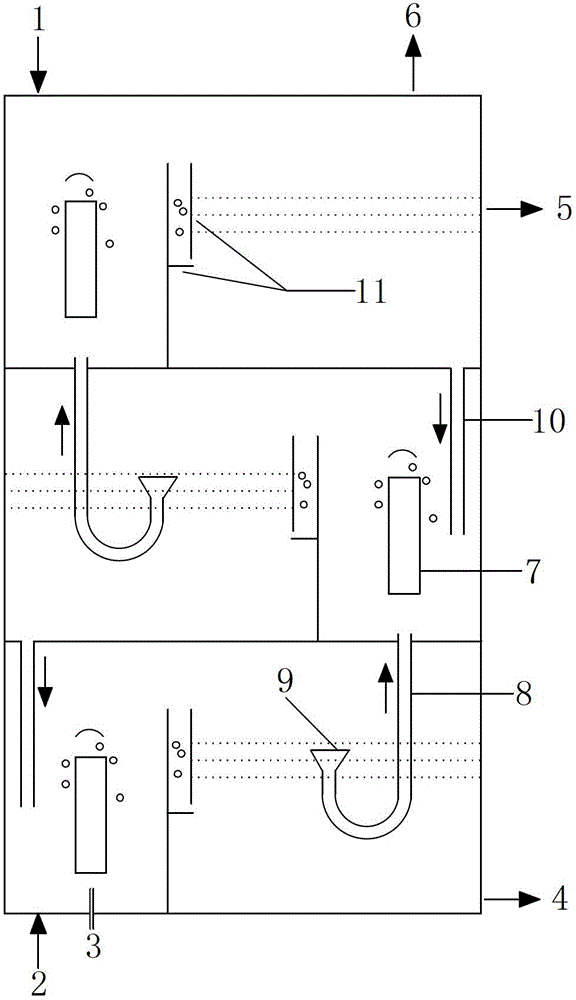

Vertical multi-stage mixing clarifying extracting device by air stirring and extracting method thereof

InactiveCN102772914BAvoid emulsificationMeet industrial mass productionLiquid solutions solvent extractionSolid solvent extractionEngineeringMixing tank

The invention discloses a vertical multi-stage mixing clarifying extracting device by air stirring. The device comprises 3-30 stages of extracting tanks which are stacked via the way of interlacing and are connected in series from bottom to top; each extracting tank is divided into a mixing tank and a clarifying tank; and the mixing tanks and the clarifying tanks are alternatively arranged left and right. An air stirrer is arranged inside the mixing tank. The extracting method comprises the steps that: firstly, air is added through an air inlet; a heavy phase enters into the mixing tank through a heavy phase inlet; a light phase enters into the mixing tank through a light phase inlet; the heavy phase is fallen and the light phase is risen; the heavy phase and the light phase are cut and smashed in the mixing tank; the cut light phase liquid drops and heavy phase liquid drops are completely mixed to be extracted; when the liquid level is higher than a clapboard; the mixing liquid of the heavy phase and the light phase enters into the clarifying tank, so that standing splitting-phase is performed; the light phase overflows into a pipe and is carried to the next-stage mixing tank by the gas; the heavy phase flows into the former-stage mixing tank; and the process is repeated, so that multi-stage extraction is finished. The extracting device is especially suitable for an easily emulsified system; and uniform mixing can be achieved under the condition of the clearness of a two-phase interface, so that the extracting process is finished.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Dendritic epoxy resin, its preparation method and its application

ActiveCN110437424BShort reaction cycleSimple production processEpoxy resin adhesivesEpoxy resin coatingsPolymer scienceAdhesive

The invention discloses a dendritic epoxy resin, a preparation method and an application thereof, and belongs to the field of dendritic polymers. Its technical scheme includes adding aliphatic polyglycidyl ether monomers and monoamino polyhydroxy monomers into the reactor, prepolymerizing at 25°C-100°C for 0.1-10 hours to form polymerized monomers; then raising the temperature to To 50°C-200°C, react for 0.5-120 hours to obtain a dendritic polymer, and prepare a dendritic epoxy resin on this basis. The invention is applied to adhesives or coatings, and solves the problem that the existing dendritic epoxy resins cannot better retain dendritic structures and epoxy groups, thus affecting the application performance of dendritic epoxy resins, and has the ability to perfectly retain Dendritic structure and epoxy group, short reaction cycle, simple production process, low cost, can meet the characteristics of large-scale industrial production, adhesion and bonding performance improvement.

Owner:WEIHAI CY DENDRIMER TECH

A kind of preparation method of magnesium-based composite material applied to automobile differential bracket

ActiveCN111804886BReduce material densityFunction increaseCasting cleaning apparatusMagnesium matrix compositeHigh entropy alloys

The invention relates to a preparation method of a magnesium-based composite material applied to an automobile differential bracket, and relates to a preparation method of a composite material applied to an automobile differential bracket. The invention aims to solve the technical problem that the existing AZ91D magnesium alloy replaces the aluminum alloy and is used for the insufficient strength of the bracket of the differential gear of the automobile. In the present invention, high-entropy alloy particles are added to the AZ91D magnesium alloy melt by rotary blowing and two-way stirring, which can reduce the stirring time, and the effect of agglomeration of the broken particles is remarkable; mechanical vibration in the X and Y directions at the same time is beneficial to the particle agglomeration in the broken side wall area, making the edge The particles in the wall area are stirred into the middle of the melt with shearing and fully mixed with the melt; a screen is placed on the surface of the molten metal in the barrel to filter the oxidized slag inclusions, and finally the extrusion casting process is used to prepare the product. The high-entropy alloy particles of the invention are uniformly dispersed, the strength and hardness of the product are also greatly improved, there is no oxidized slag inclusion defect inside the product, the particles are well combined with the matrix, and the application of the magnesium-based composite material can be further broadened.

Owner:哈尔滨吉星机械工程有限公司

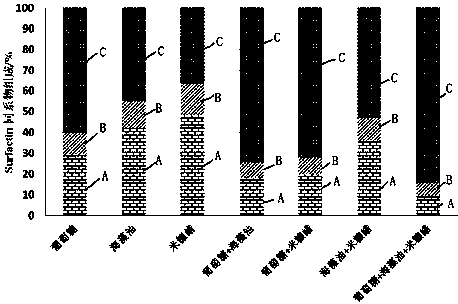

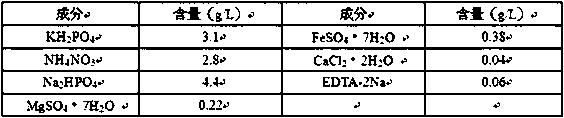

A fermentation culture method capable of increasing the yield of subtilis lipopeptide sodium

ActiveCN106119323BEasy to synthesizeIncrease productionMicroorganism based processesFermentationSubtilisinTert-leucine

Owner:PROYA COSMETICS

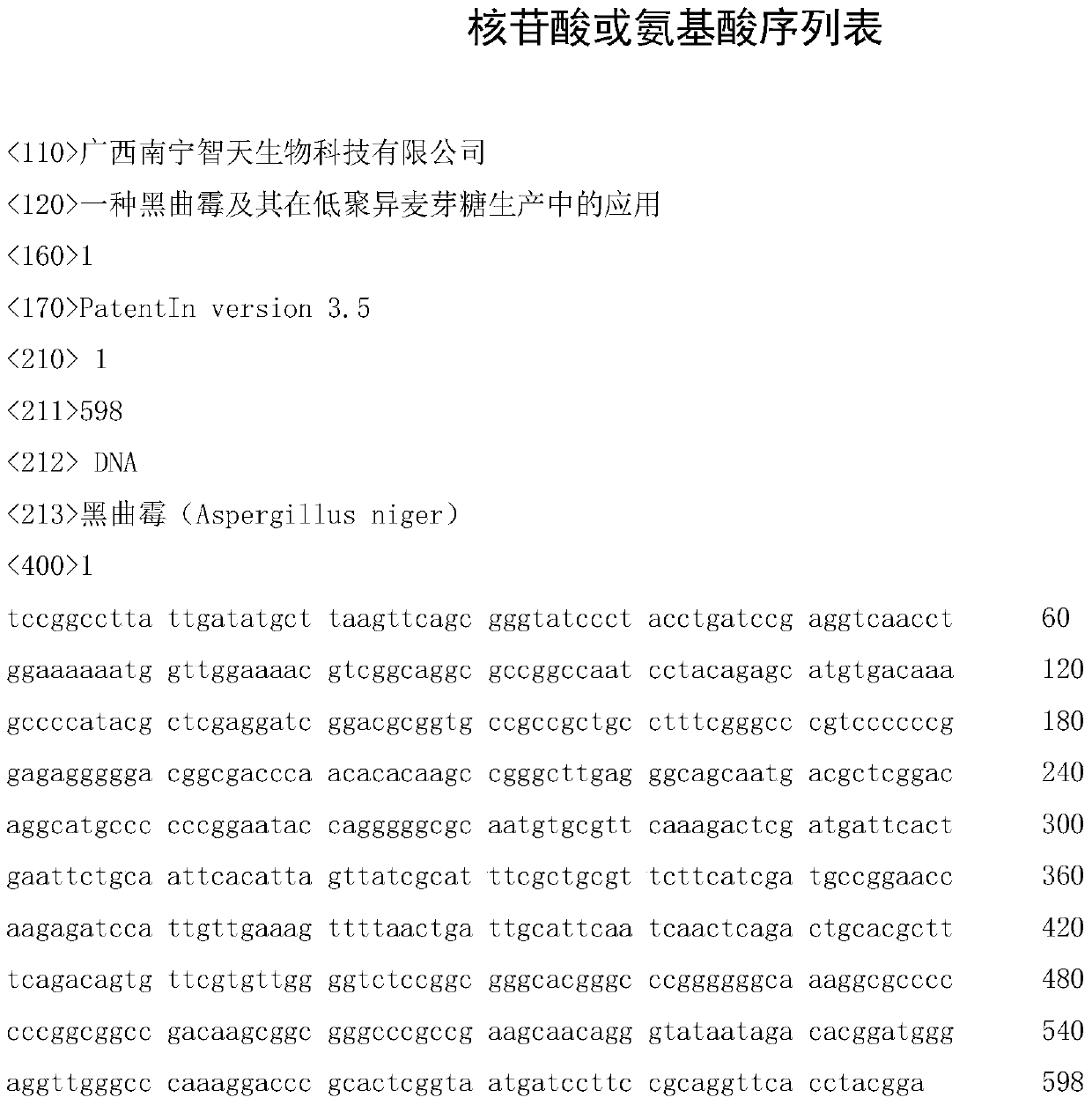

A kind of Aspergillus niger and its application in the production of isomaltooligosaccharide

ActiveCN104877911BSimple nutritional requirementsThe cultivation method is simpleFungiMicroorganism based processesAlgluceraseIsomaltooligosaccharide

The invention discloses an Aspergillus niger, which is classified as Aspergillus niger (Aspergillus niger) M1, the preservation number CCTCC NO: M2014421, and the preservation date is September 23, 2014. The preservation unit: China Center for Type Culture Collection, the Aspergillus niger The α-glucosidase produced by the (Aspergillus niger) M1 strain is an intracellular enzyme, which can produce isomaltooligosaccharides with an effective trisaccharide (IG+P+IG3) content of more than 65% at a high temperature of 55-65 °C, while The reaction time required to prepare IMO‑500 type isomaltooligosaccharide with an effective trisaccharide content of 35% is only half of the reaction time for preparing isomaltooligosaccharide with an effective trisaccharide content of more than 65%. The α-glucosidase produced by the bacterial strain of the present invention has the advantages of excellent temperature characteristics, short glucoside conversion time, high effective trisaccharide content of the product, and the like.

Owner:GUANGXI NANNING ZHITIAN BIOTECH

A kind of nanofiber chitosan porous material and preparation method thereof

ActiveCN110982124BAppropriate hot water dissolution rateAppropriate swelling ratePolymer sciencePolyvinyl alcohol

The invention discloses a nanofiber chitosan porous material and a preparation method thereof. The nanofiber chitosan porous material is obtained by preparing chitosan solution and polyvinyl alcohol-ethylene copolymer nanofiber suspension respectively, mixing them uniformly in proportion, and freeze-drying. Through the above method, the present invention can make polyvinyl alcohol-ethylene copolymer nanofibers evenly dispersed on the inner wall surface of chitosan main body, improve the problems of traditional chitosan porous materials such as low strength, easy dissolution, low service life, etc. The obtained porous material has relatively suitable hot water dissolution rate, swelling rate, water content and compressive strength, so as to meet the needs of practical applications. The preparation method of the nanofiber chitosan porous material is simple and feasible, and can meet industrial large-scale production; and the performance of the prepared porous material can be regulated by adjusting the ratio of nanofibers and chitosan to adapt to different application scenarios , a wide range of applications.

Owner:WUHAN TEXTILE UNIV

Screen Air Dryer

ActiveCN104329926BEnsure safetyGuaranteed safe operationDrying gas arrangementsHigh volume manufacturingPulp and paper industry

Owner:HEBEI JING LONG SUN EQUIP

Refining method of disodium phosphocreatine

ActiveCN102295658BSimple processing methodMild and easy to controlGroup 5/15 element organic compoundsPhysical chemistrySolvent

The invention discloses a refining method of disodium phosphocreatine. The method comprises steps that: a sodium phosphocreatine crude product is dissolved in water, the solution is filtered, and a micro-molecular solvent is dropped into the filtrate while stirring, such that a large amount of oily matters are precipitated; the oily matters are settled and precipitated, a supernatant is removed, methanol is dropped into the oily matters while stirring, a large amount of crystals are precipitated, and the crystals are beaten and filtered; the filter cake is transferred into a reaction bottle, washed by using a micro-molecular solvent while stirring, and is filtered; the filter cake is dried with reduced pressure at a temperature of 40 to 45 DEG C, such that disodium phosphocreatine tetrahydrate with a high quality is obtained. The refining method provided by the invention has advantages of mild technical condition, simple and easy-to-control method, high yield, and stable product quality. The method satisfies the requirement of large-scale productions, and brings in good social and economic benefits.

Owner:重庆莱美隆宇药业有限公司

A kind of dendritic tryptophan compound, its preparation method and its application as antibacterial agent

ActiveCN111574710BShort reaction cycleSimple production processAntibacterial agentsOrganic active ingredientsCarboxyl radicalTryptophan

The invention discloses a dendritic tryptophan compound, its preparation method and its application as an antibacterial agent, and belongs to the technical field of dendritic polymer synthesis. Its technical scheme includes adding carboxyl-terminated polyamide-amine dendrimer and alkyl esterified tryptophan to hydrochloric acid and N,N-dimethylformamide solution, and reacting at 20°C-60°C for 3-10 days, A compound containing a tryptophan group at the end is obtained; the above-mentioned compound containing a tryptophan group at the end is subjected to rotary evaporation, washing and drying, and the obtained residue is purified by high performance liquid chromatography to obtain a preliminary purified tryptophan at the end. compounds with acid groups. The invention is applied to the field of antibacterial agents, solves the problem of poor antibacterial effect when the existing antibacterial agent treats microorganisms with complex composition, and has the characteristics of simple preparation method, good antibacterial effect and broad-spectrum antibacterial property.

Owner:WEIHAI CY DENDRIMER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com